Polypropylene microporous membrane with three-layer compound structure and preparation method thereof

A polypropylene microporous film, three-layer structure technology, applied in the field of microporous film, can solve problems such as poor safety and inability to ensure battery safety, achieve low closed-cell temperature, prevent abnormal battery temperature rise, and avoid internal short circuits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

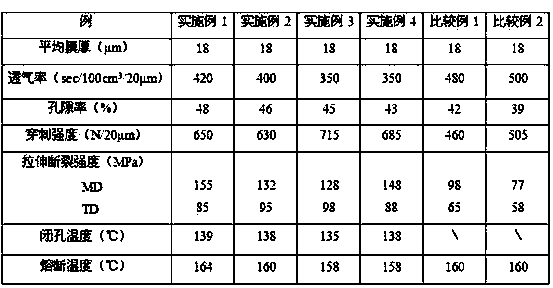

Examples

Embodiment 1

[0023] 1) 0.1% by weight of terephthalic acid, 0.1% by weight of barium oxide and 99.8% by weight of homopolypropylene were mixed and extruded to obtain β-crystal homopolypropylene, and its β-crystal content was measured to be 82%, the melt index is 8, the crystallinity is 62%, and the melting point is 165°C.

[0024] 2) 0.1% by weight of terephthalic acid, 0.1% by weight of barium oxide and 99.8% by weight of ethylene-propylene copolymerized polypropylene were mixed and extruded to obtain β-crystal copolymerized polypropylene, and the content of β-crystal form was measured to be 79%, the melt index is 15, the crystallinity is 51%, and the melting point is 141°C.

[0025] 3) The above-mentioned β-crystal homopolypropylene is used as the raw material of the surface layer A and surface layer C, and the above-mentioned β-crystal copolymerized polypropylene is used as the raw material of the core layer B, which are respectively melted and kneaded at 220°C and then compounded by th...

Embodiment 2

[0029] 1) Mix and extrude 0.5% by weight of azelaic acid, 1% by weight of calcium stearate and 98.5% by weight of homopolypropylene to obtain β-crystal homopolypropylene, and measure its β-crystal content It is 89%, the melt index is 7, the crystallinity is 60%, and the melting point is 162°C.

[0030] 2) Mix and extrude 0.5% by weight of azelaic acid, 1% by weight of calcium stearate and 98.5% by weight of ethylene-propylene-butylene ternary copolymerized polypropylene to obtain β-crystalline copolymerized polypropylene, and measure its β-crystalline The molar content is 78%, the melt index is 16, the crystallinity is 44%, and the melting point is 140°C.

[0031] 3) The above-mentioned β-crystal copolymerized polypropylene is used as the raw material of the surface layer A and the surface layer C, and the above-mentioned β-crystal homopolypropylene is used as the raw material of the core layer B, which are respectively melted and kneaded at 210°C and then compounded by three ...

Embodiment 3

[0035] 1) 1% by weight of adipic acid, 2% by weight of calcium carbonate and 97% by weight of homopolypropylene were mixed and extruded to obtain β-crystal homopolypropylene I, and its β-crystal content was measured to be 88%, the melt index is 6.5, the crystallinity is 58%, and the melting point is 163°C. 1.5% by weight of phthalimide, 3% by weight of magnesium oxide and 95.5% by weight of homopolypropylene were mixed and extruded to obtain β-crystal homopolypropylene II, and its β-crystal content was measured It is 85%, the melt index is 7.2, the crystallinity is 60%, and the melting point is 160°C.

[0036] 2) Mix and extrude 1% by weight of adipic acid, 2% by weight of calcium carbonate and 97% by weight of ethylene-propylene-butylene ternary copolymerized polypropylene to obtain β-crystal form copolymerized polypropylene, and measure its β-crystal form content It is 80%, the melt index is 18, the crystallinity is 43%, and the melting point is 138°C.

[0037] 3) The above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com