Method for separating methoxamine from distillation liquid by using electrodialysis

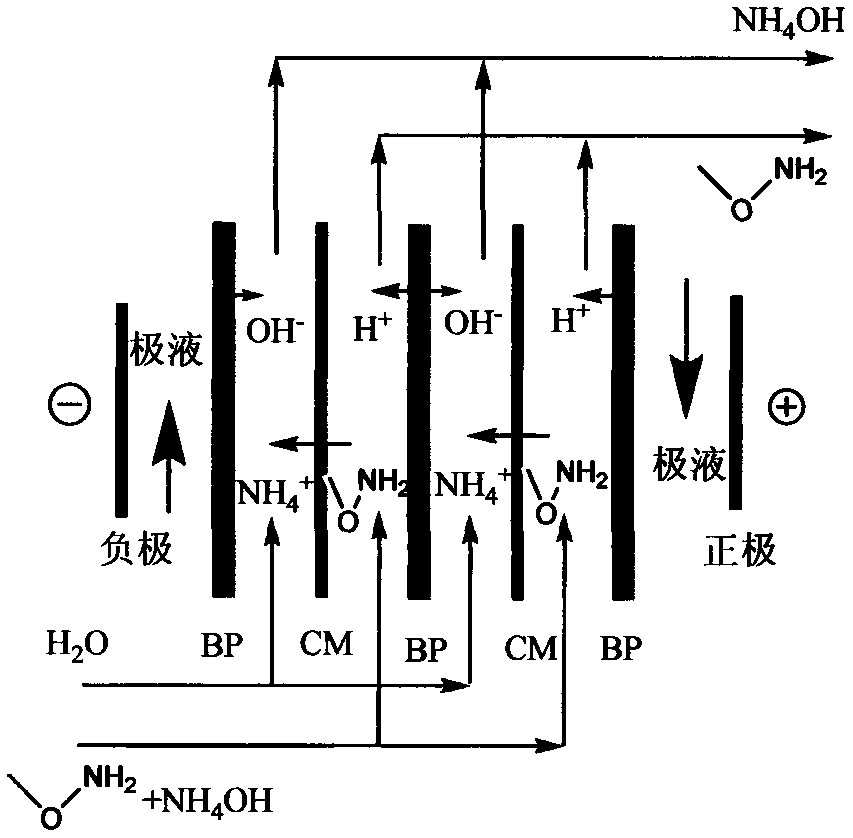

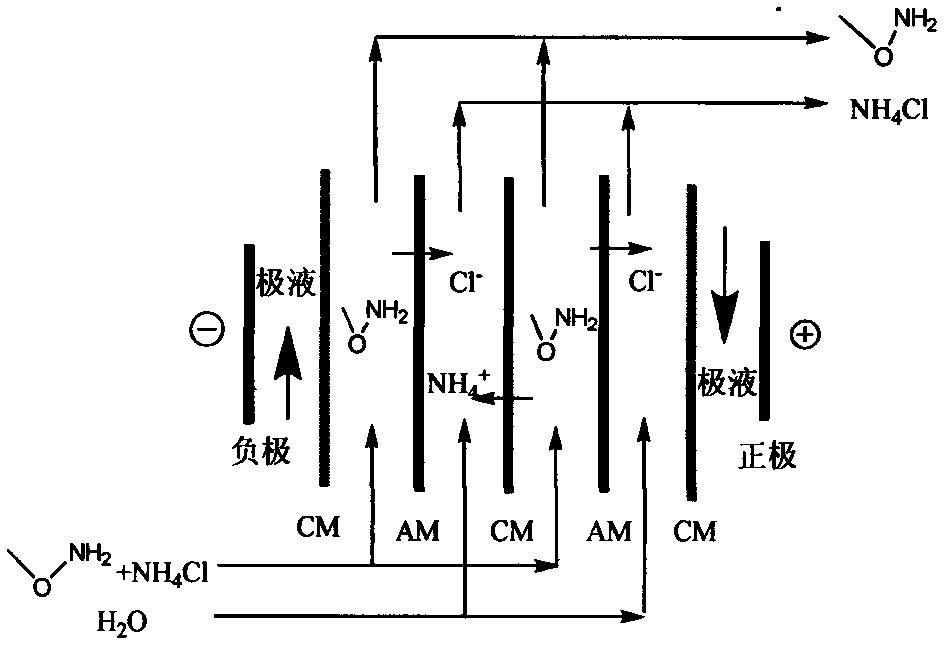

A technology of methoxyamine and electrodialysis, applied in the direction of electrodialysis, etc., can solve the problems of high energy consumption and low quality of methoxyamine separation, achieve the effects of reducing energy consumption, reducing environmental pollution, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

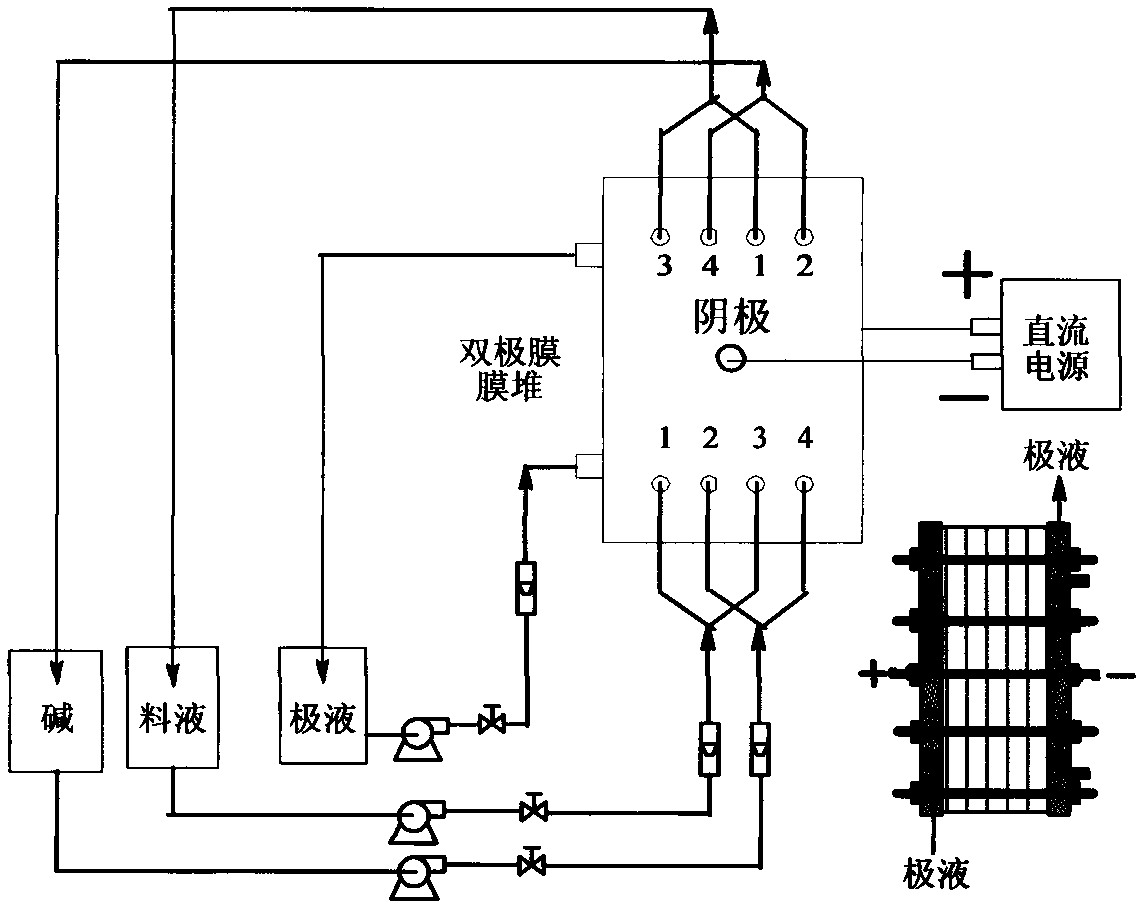

Embodiment 1

[0017] Take 0.5L of the methoxyamine extraction solution after microporous filtration, containing 9.42% of methoxyamine and 1% of ammonia, and pump it into five groups of 9*21cm two-compartment bipolar membrane electrodialysis membrane stacks for salt chamber, pump 0.5L pure water into the alkali chamber, pump 0.5L sodium sulfate with a concentration of 3% into the electrode solution chamber, seal all compartments, and circulate at a flow rate of 25L / h, connect the DC power line to the membrane stack Turn on the positive and negative poles of the DC power supply, keep the temperature at 25°C, and control the current density to 50A / m 2 , stop when the conductance of the alkali chamber rises to 5.5ms / cm, and react for 2 hours. The content of methoxyamine obtained in the salt room was 9.14%, the ammonia was trace, and the recovery rate reached 97%, and the ammonia content in the alkali room was 0.96%. Example 2

Embodiment 2

[0018] Take 0.5L of the methoxyamine extraction solution after microporous filtration, containing 9.42% of methoxyamine and 1% of ammonia, and pump it into five groups of 9*21cm two-compartment bipolar membrane electrodialysis membrane stacks for salt room, add a small amount of hydrochloric acid, pump 0.5L pure water into the alkali room, pump 0.5L sodium sulfate with a concentration of 3% into the electrode solution room, seal all compartments, and circulate at a flow rate of 25L / h, and connect the DC power line Connect to the positive and negative poles of the membrane stack, turn on the DC power supply, keep the temperature at 25°C, and control the current density to 50A / m 2 , stop when the conductance of the alkali chamber rises to 5.5ms / cm, and the reaction lasts for 1.8h. The content of methoxyamine obtained in the salt chamber is 9.02%, the ammonia is trace, the recovery rate reaches 95.8%, and the ammonia content in the alkali chamber is 0.95%.

Embodiment 3

[0020] Take 0.5L of the methoxyamine extraction solution after microporous filtration, adjust the pH to 5.5, containing 9.42% of methoxyamine and 1% of ammonia, and pump it into 5 groups of 9*11cm two-compartment electrodialysis membrane stacks Dilute chamber, pump 0.5L pure water into the concentrated chamber, pump 0.5L sodium sulfate with a concentration of 3% into the electrode solution chamber, seal all compartments, and circulate at a flow rate of 25L / h, connect the DC power line to the membrane For the positive and negative electrodes of the stack, turn on the DC power supply, keep the temperature at 25°C, and control the current density to 100A / m 2 , Stop when the conductance of the feed solution drops to 0.5ms / cm, and react for 2 hours. The content of methoxyamine obtained in the thin chamber is 8.98%, the amount of ammonia is trace, the recovery rate reaches 95.3%, and the content of ammonium chloride in the thick chamber is 2.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com