Flavor-enhancing puffed tobacco stem granules and its preparation method and application

A technology of tobacco stems and granules, which is applied in the field of flavoring puffed tobacco stalk granules and its preparation, can solve the problems of poorly maintaining the consistency of tobacco leaf odor, increasing shutdown accidents, and loss of tobacco leaf raw materials, and achieves the reduction of raw material measurement and mixing The effect of mixing process, reducing production process, and increasing adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Formation of the internal microporous structure of the tobacco stem: Take 200 g of the tobacco stem, spray 20 g of Tris-HCl buffer solution (0.02 g of pectinase and 0.02 g of cellulase in the buffer solution) on the surface of the tobacco stem; Constant temperature enzymatic hydrolysis for 4 hours.

[0036] (2) Fixing and shaping of the internal microporous structure of the tobacco stem: spread the tobacco stem obtained through enzymatic hydrolysis on a microwave oven, and microwave it under high fire conditions (120° C.) for 90 seconds.

[0037] (3) Re-fixation of the internal microporous structure of the tobacco stem: adding 0.1% aqueous gum arabic solution to the puffed tobacco stem and soaking for 1 hour.

[0038] (4) Drying and crushing of the fixed tobacco stems: drying the tobacco stems in a constant temperature oven for 30 minutes at 70° C.; crushing the tobacco stems with a pulverizer. Remove the granular pulverized matter below 30 mesh and above 60 mesh, ...

Embodiment 2

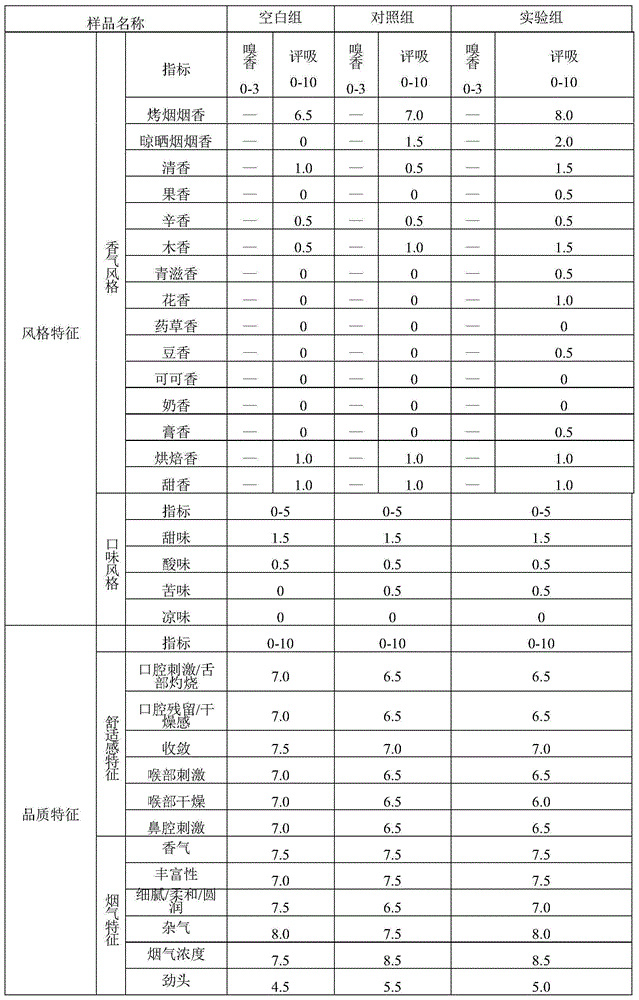

[0041] The experiment was divided into blank group, control group and experimental group. In the blank group, no filter material is added to the filter tip, in the control group, ordinary tobacco stem particles are added to the filter tip, and in the experimental group, tobacco stem particles prepared by the method described in Example 1 are added to the filter tip.

[0042] Table 1

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com