Nickel cobalt lithium aluminate positive material and preparation method thereof

A technology of lithium nickel cobalt aluminate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc. Performance deterioration and other problems, to avoid uneven distribution of components, high production efficiency, high product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

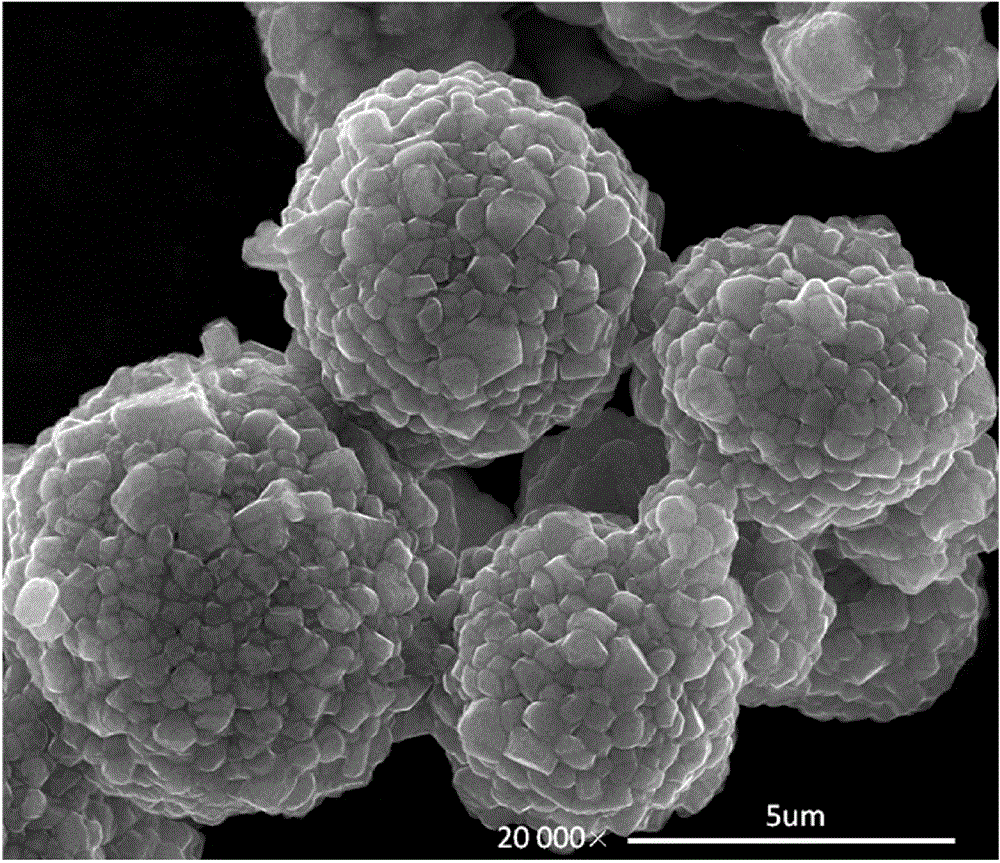

[0026] The molar ratio of Ni:Co:Al is 0.8:0.15:0.05 and nickel hydroxide, cobalt tetraoxide and aluminum oxide are mixed, and then according to the mass ratio of material:ball:water=1:1:5, after ball milling for 5h and mixing evenly, The ball-milled slurry is spray-dried; the dried powder is calcined in oxygen at 500° C. for 4 hours, and the precursor is obtained after cooling.

[0027] Mix the above-mentioned roasted nickel-cobalt lithium aluminate positive electrode material precursor and lithium carbonate according to the ratio of Li:(Ni+Co+Al) of 1.05:1, ball mill for 2 hours and mix evenly, then spray-dry the slurry, and after drying The powder was calcined at 900° C. for 8 hours, the sintering atmosphere was an oxygen atmosphere, cooled, pulverized, and sieved to obtain a nickel-cobalt-lithium-aluminate cathode material.

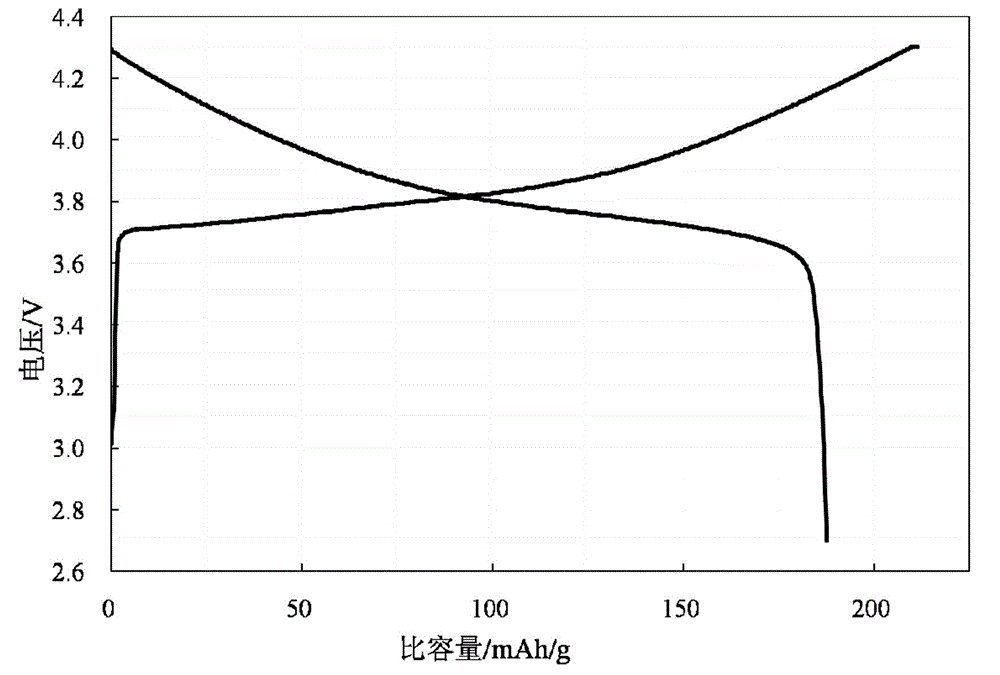

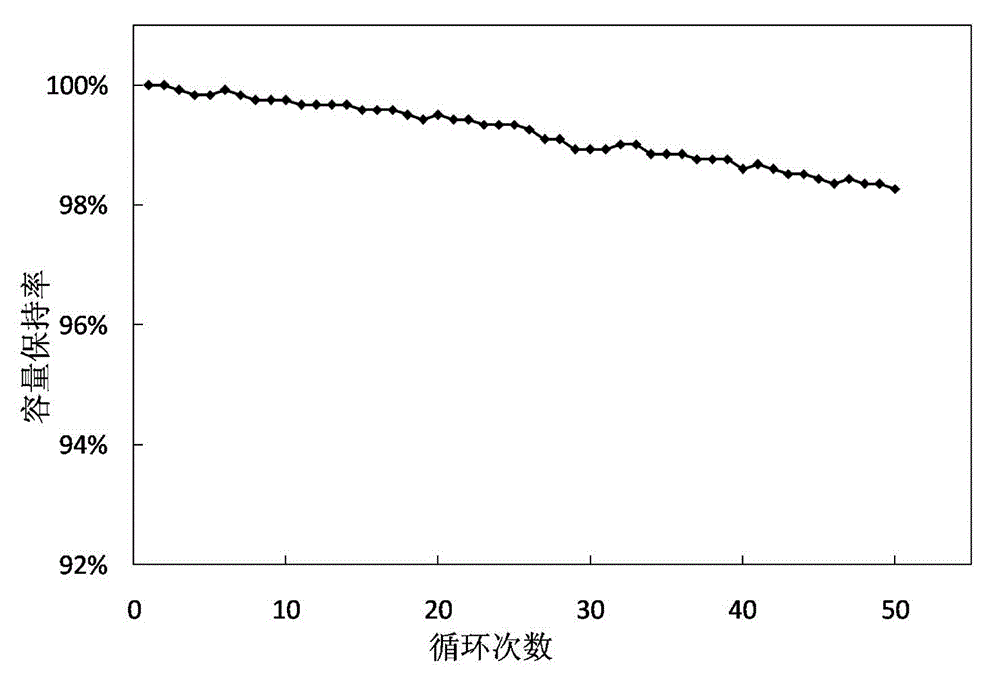

[0028] The electrochemical performance test of the material is tested at 25°C with the blue battery test system, and the test voltage range is 2.7V to...

Embodiment 2

[0030] The molar ratio of Ni:Co:Al is 0.75:0.2:0.05 and nickel hydroxide, cobalt tetraoxide and aluminum oxide are mixed, and then according to the mass ratio of material:ball:water=1:1:5, ball milling is carried out for 6h after mixing evenly, The ball-milled slurry was spray-dried; the dried powder was calcined in oxygen at 600° C. for 4 hours, and the precursor was obtained after cooling.

[0031] Mix the above-mentioned roasted nickel-cobalt lithium aluminate positive electrode material precursor and lithium carbonate according to the ratio of Li:(Ni+Co+Al) of 1.05:1, ball mill for 3 hours and mix evenly, then spray-dry the slurry, and after drying The powder was calcined at a high temperature of 950°C for 6 hours, the sintering atmosphere was an oxygen atmosphere, cooled, pulverized, and sieved to obtain a nickel-cobalt-lithium-aluminate positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com