Modification method of lithium-enriched manganese-based solid solution lithium battery cathode material

A lithium-rich manganese-based, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as affecting the discharge specific capacity of the material, and achieve the advantages of transmission, controllable thickness of the coating, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

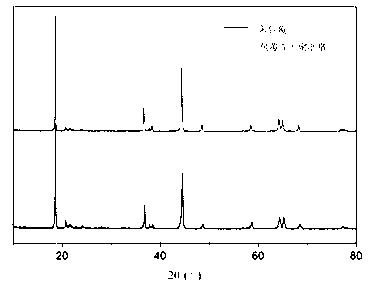

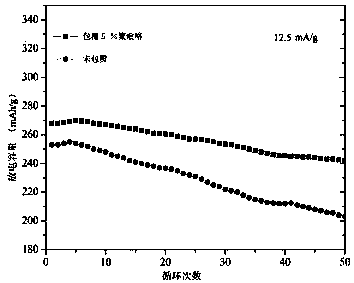

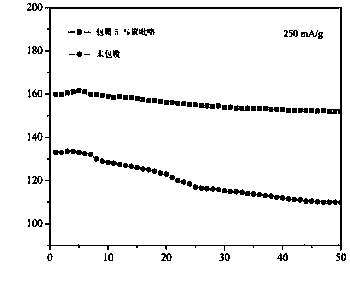

[0032] This embodiment is 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 The preparation method of coating 5% polypyrrole lithium battery cathode material specifically comprises the following steps:

[0033] (1) Weigh NiSO according to the molar ratio of Ni: Co: Mn=1: 1: 4 4 、CoSO 4 , MnSO 4 , to obtain a metal salt mixture after mixing;

[0034] (2) Dissolve the above metal salt mixture in deionized water to prepare 200 mL of a solution with a total metal ion concentration of 1mol / L;

[0035] (3) Prepare 200 mL of sodium carbonate solution with a concentration of 1 mol / L, add ammonia water as a complexing agent, and the concentration of ammonia water is 0.1 mol / L;

[0036] (4) Continuously input the metal salt solution and sodium carbonate solution into the reaction flask with a peristaltic pump, the flow rate is 5mL / min, the water bath temperature of the reactor is 55°C, the slurry pH=7-8, and the stirring speed is 600 rpm;

[0037] (5) After the reaction, the preci...

Embodiment 2

[0043] This embodiment is 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 The preparation method of coated 2% polypyrrole lithium battery cathode material specifically comprises the following steps:

[0044] Steps (1)-(6) are the same as in Example 1;

[0045] (7) Weigh 10 g of the prepared 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 and 0.2g of pyrrole monomer are dispersed in 100 mL of perchloric acid aqueous solution with a concentration of 0.1mol / L, and the ultrasonic dispersion is uniform;

[0046] (8) According to the molar ratio of ferric p-toluenesulfonate to the above-mentioned pyrrole as 1:1, weigh 2 g of ferric p-toluenesulfonate to make 100 mL ferric p-toluenesulfonate perchloric acid solution with a concentration of 0.1mol / L, Then this p-toluenesulfonate ferric perchloric acid solution is added in the solution of the above-mentioned step (7), stirred and reacted for 8h;

[0047] (9) After the reaction product was filtered, centrifuged, washed, and d...

Embodiment 3

[0049] This embodiment is 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 The preparation method of coating 7% polyaniline lithium battery cathode material specifically comprises the following steps:

[0050] Steps (1)-(6) are the same as in Example 1;

[0051] (7) Weigh 10 g of the prepared 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 and 0.7g of aniline monomer were dispersed in 100 mL of hydrochloric acid aqueous solution with a concentration of 0.2mol / L, and the ultrasonic dispersion was uniform;

[0052] (8) According to the molar ratio of ammonium persulfate to the above-mentioned aniline as 1:2, weigh 0.86 g of ammonium persulfate to prepare 100 mL of ammonium persulfate hydrochloric acid solution with a concentration of 0.2mol / L, and then dissolve the hydrochloric acid of ammonium persulfate The solution was added to the solution of the above step (7), and the reaction was stirred for 12h;

[0053] (9) After the reaction product was filtered, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com