Pyrolysis furnace and treatment process for treating waste tire

A pyrolysis furnace and waste tire technology, applied in coking ovens, petroleum industry, recycling technology, etc., can solve the problems of reducing system thermal efficiency, easy leakage of rotating parts and static parts, and non-continuous operation, so as to avoid instability, Uniform heating, highlighting the effect of substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

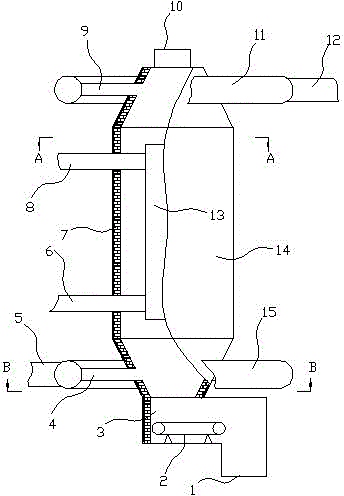

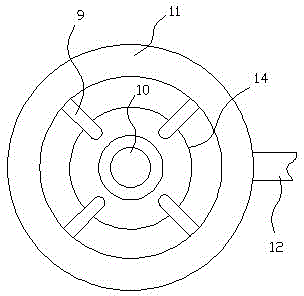

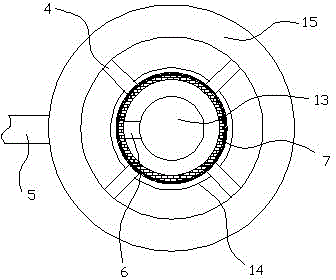

[0025] In order to clearly illustrate the technical characteristics of this scheme, the following is a detailed description of this scheme through a specific implementation method with a processing capacity of 100 kg per hour for waste tires, combined with its accompanying drawings.

[0026]As can be seen from the accompanying drawings, the pyrolysis furnace for pyrolytic treatment of waste tires in this program includes a furnace body 14 with a furnace lining 7, a feed port 10 and a discharge port 1, and the furnace body 14 is made of Q235 carbon The shell made of steel plate is composed of the furnace lining 7 made of aluminum silicate refractory fiber felt and high alumina refractory bricks. The furnace body 14 described in this program is cylindrical, and the ratio of the height to the outer diameter of the furnace body 14 is 2.0-4.0. In this specific embodiment, the outer diameter of the furnace body 14 is 0.9 meters, and the height of the furnace body 14 is 3.6 meters. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com