Method for rapidly producing high-quality organic fertilizer by virtue of high-temperature aerobic secondary fermentation

A technology of secondary fermentation and high temperature fermentation, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, which can solve the problems of wasting resources, polluting the atmosphere, and affecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

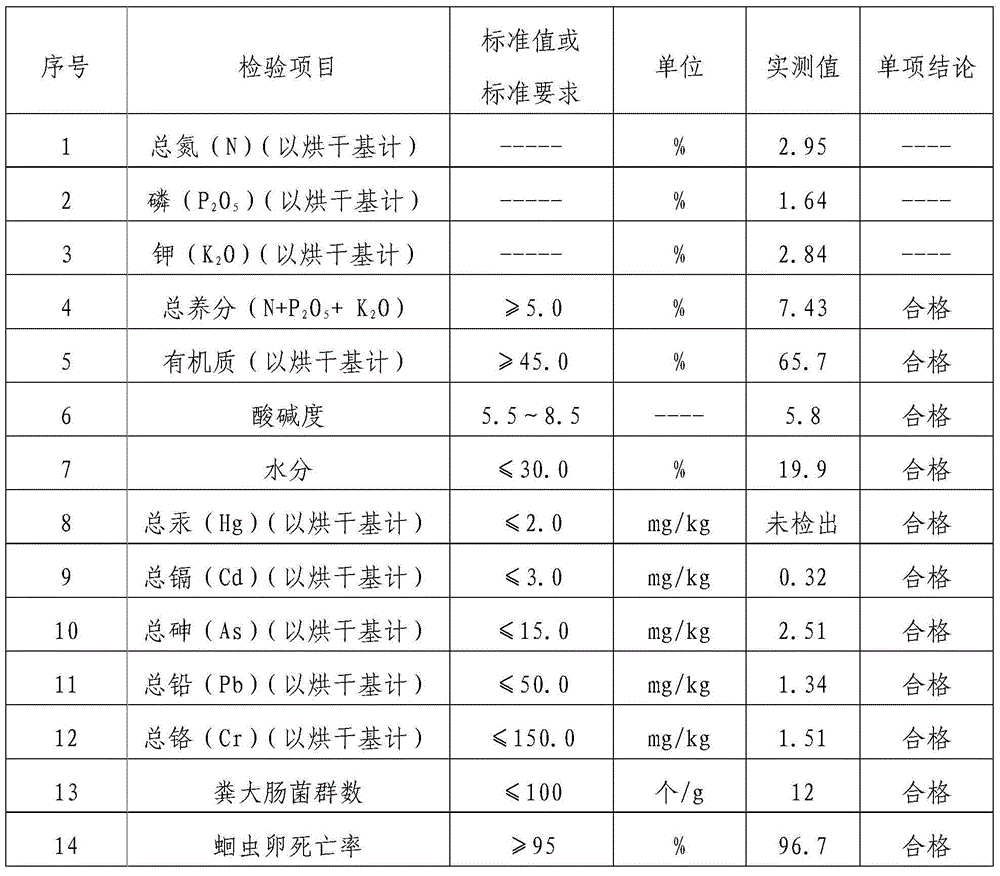

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment, the present invention will be further described. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

[0040] The high-temperature aerobic secondary fermentation method of the present embodiment produces the method for high-quality organic fertilizer rapidly, and its technological process is as follows:

[0041] A. Raw material pretreatment:

[0042] Crush the organic waste to be treated [including one or more of organic waste, kitchen waste, straw, plant (including trees, shrubs, grass, etc.) branches and leaves, human and animal manure, etc.) to 35 meshes, and add carbon or For nitrogen-containing raw materials, adjust the carbon-to-nitrogen ratio to 30:1, adjust the water content to 45%, and adjust the pH value to 5.5 to become raw materials to be processed and set aside;

[0043] B. Production of fermentation agent:

[0044] a. Production of high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com