Method for purifying penicillin production waste liquid and recycling sodium sulfate

A technology of sodium sulfate and penicillin is applied in chemical instruments and methods, alkali metal sulfite/sulfate purification, energy and wastewater treatment, etc. Significant economic and environmental benefits, reducing governance difficulty and costs, and recycling green effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

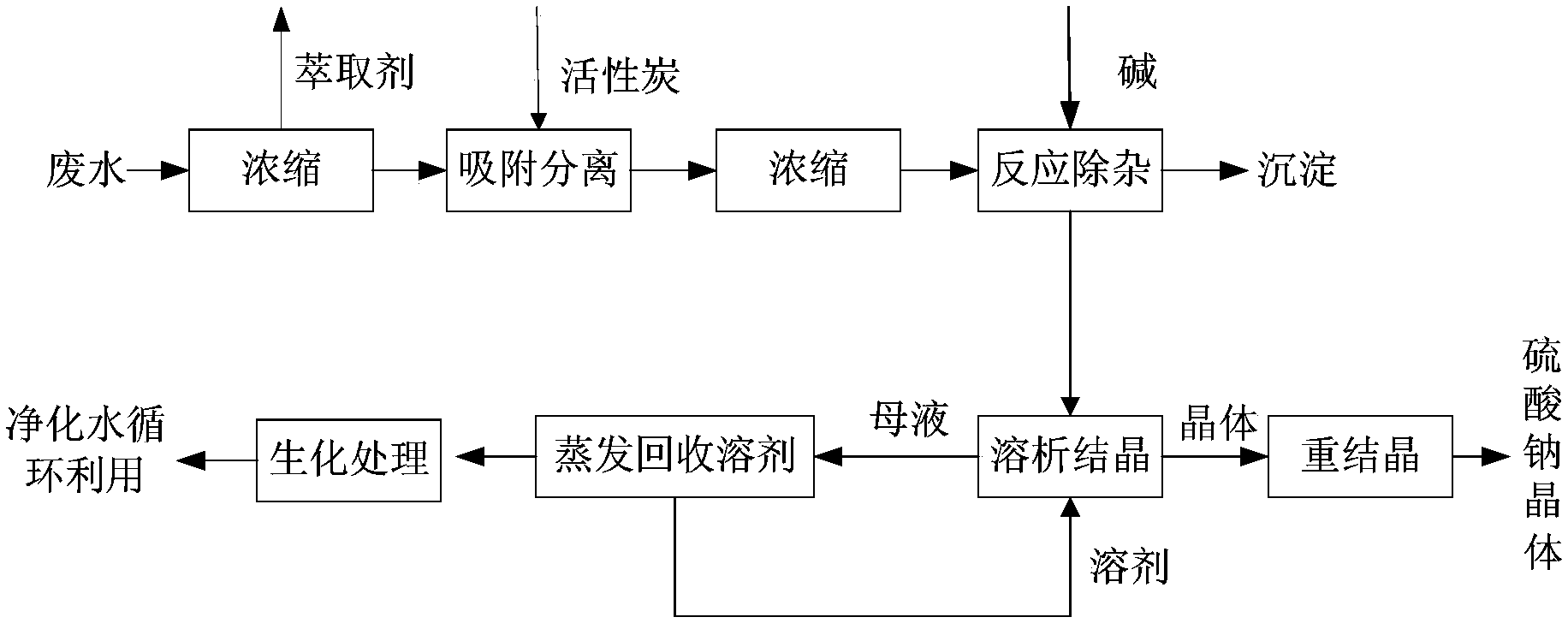

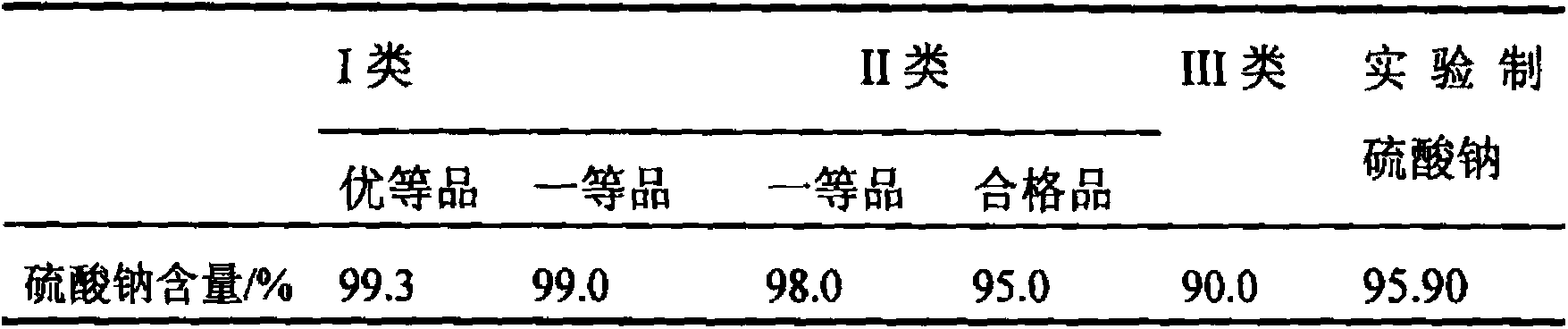

[0023] The process of purifying penicillin production waste liquid and recovering sodium sulfate, such as figure 1 shown.

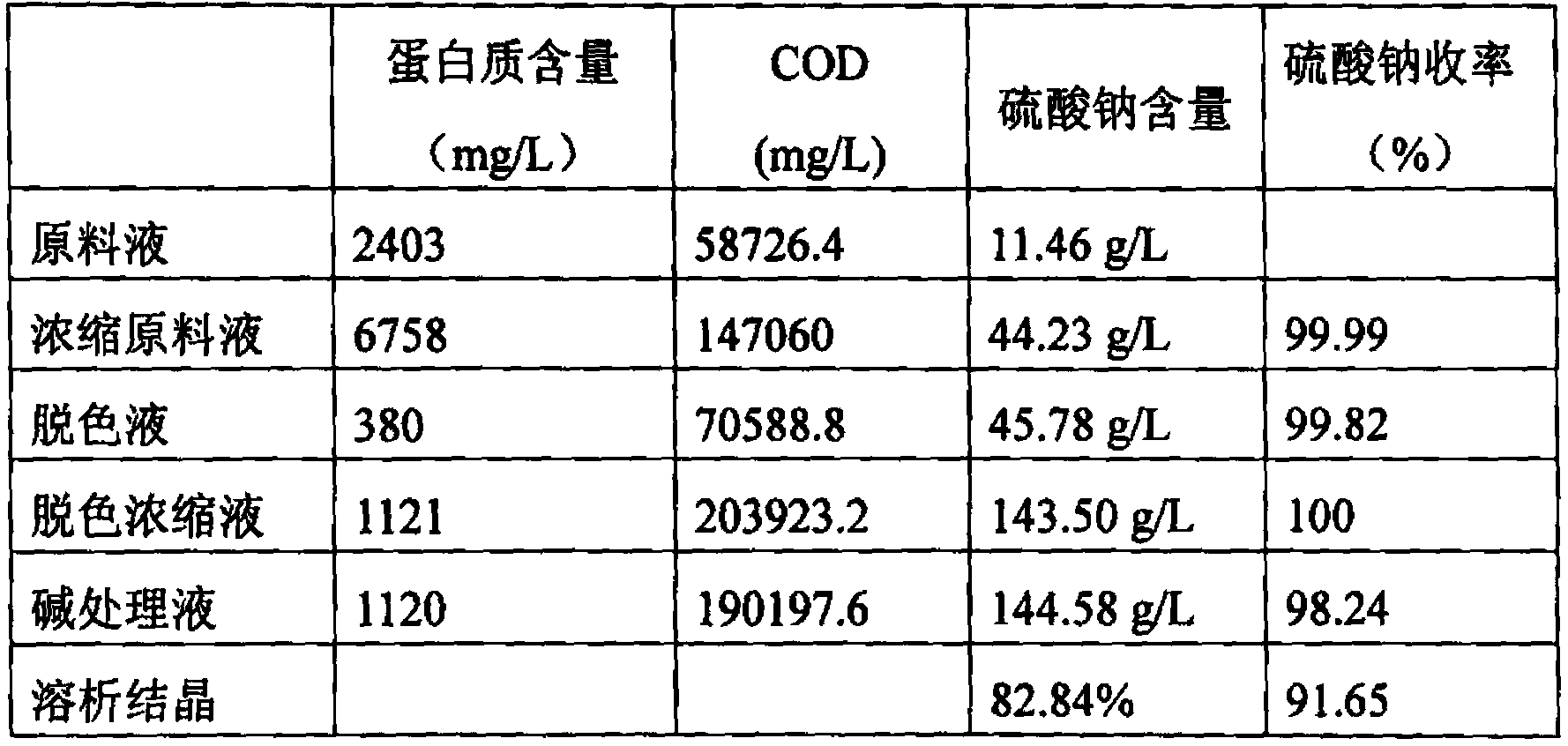

[0024] The content of sodium sulfate in the penicillin wastewater used in the experiment was 11.4618g / L.

[0025] Concentrate the raw material waste liquid by a certain number of times (volume is about 1 / 4 of the raw material liquid), so as to fully remove the butyl acetate in the raw material liquid. Add 1 g of powdered activated carbon to the concentrated raw material solution per 100 mL of waste liquid, heat and stir at 80 ° C for 1 h, and filter to obtain a decolorized solution. The decolorizing solution is heated, evaporated and concentrated, and the concentration is stopped when the volume is about one-third of the decolorized solution, and the decolorized concentrated solution is cooled. Add solid NaOH to the decolorized concentrated solution and keep stirring until the liquid changes from acidic to neutral, with a pH of about 7.0-7.2, and filter...

Embodiment 2

[0034] A method for purifying penicillin production waste liquid and reclaiming sodium sulfate, such as figure 1 shown, including the following steps:

[0035] (1) the penicillin production waste liquid first flows into the evaporator and carries out preliminary evaporation, evaporates the extractant butyl acetate in the fermentation filtrate, and continues to evaporate to obtain the concentrated raw material solution that the sodium sulfate concentration is 40g / L;

[0036] Among them, the penicillin fermentation feed liquid is separated from the solid and liquid to obtain the filtrate, and the filtrate is extracted with butyl acetate, and the raffinate is the penicillin production waste liquid. The content of sodium sulfate in the penicillin production cost is 9g / L, and the protein content It is 1.8g / L, COD is 40000mg / L.

[0037] (2) Add activated carbon to the concentrated raw material solution, add 0.5 g of activated carbon to every 100 ml of concentrated raw material solu...

Embodiment 3

[0043] A method for purifying penicillin production waste liquid and reclaiming sodium sulfate, such as figure 1 shown, including the following steps:

[0044] (1) the penicillin production cost first flows into the evaporator for preliminary evaporation, evaporates the extractant butyl acetate in the fermentation filtrate, and continues to evaporate to obtain the concentrated raw material solution that the sodium sulfate concentration is 50g / L;

[0045] Among them, the penicillin fermentation feed liquid is obtained after solid-liquid separation, and the filtrate is extracted with butyl acetate, and the raffinate is the penicillin production waste liquid. The content of sodium sulfate in the penicillin production waste liquid is 15g / L, and the protein The content is 3g / L, and the COD is 65000mg / L.

[0046] (2) Add activated carbon to the concentrated raw material liquid, add 2 g of activated carbon to every 100 ml concentrated raw material liquid, heat to 85 ° C, and stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com