Regeneration and cyclic utilization method for linen laundry wastewater

A waste water and linen technology, applied in other washing machines, chemical instruments and methods, applications, etc., can solve the problems of complex waste water composition, lack of skilled workers, low modernization level, etc., to avoid oxygen bleaching holes and damage, process Simple, Governance Targeted Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

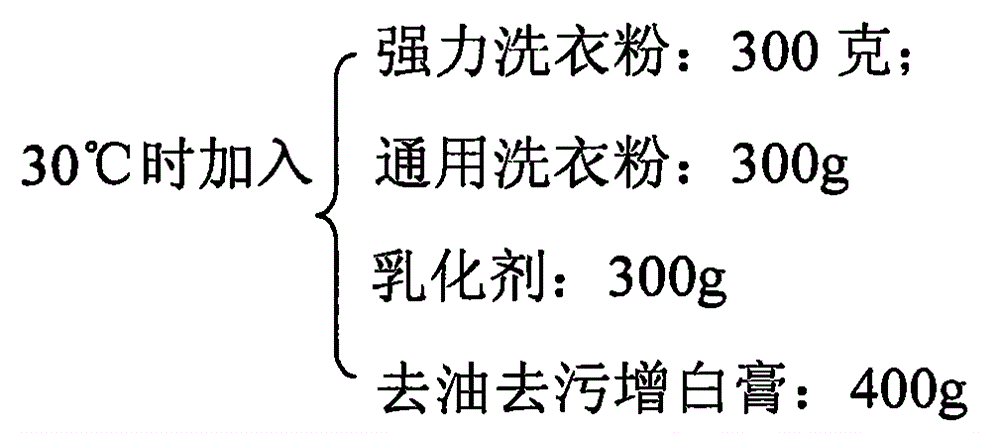

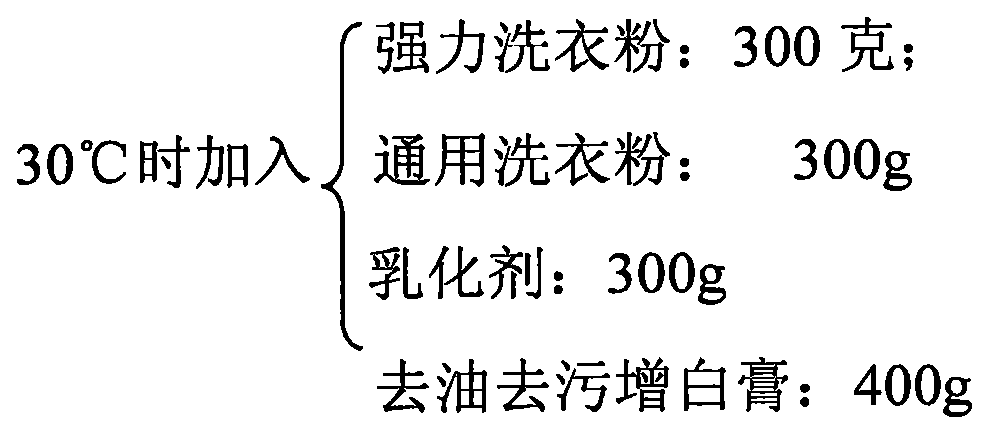

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Flocculation and separation of main wash preparation wastewater

[0040] According to the method of the content of the invention (2), weigh 2.0g of general washing powder, add 870ml of water, heat to 70°C, add 1.0g of color bleaching powder, dissolve and keep warm for 15 minutes, add 1.0ml of polymaleic acid after cooling, add 5g after stirring / L cationic organic polymer flocculant E130ml, the total volume is about 1L, after stirring, let it stand for 15 minutes, use qualitative filter paper as the filter material for static filtration, recover about 850ml of filtrate, test the pH value of the filtrate is 6, and the light transmittance is 98.0 %, the turbidity is 4.83NTU, and the surface tension is 35.6mN / m.

Embodiment 2

[0041] Example 2: Flocculation and separation of main wash wastewater for sports socks

[0042] According to the method of the content of the invention (2), take 7 sports socks weighing 100g, weigh 2.0g of general-purpose washing powder, add 870ml of water, put them into the sports socks, stir and heat to 70°C, add 1.0g of oxygen bleaching powder to dissolve, stir and keep warm for 15 minutes , take out the sports socks, the remaining raffinate is about 770ml, after cooling, add 1.0ml polymaleic acid and stir, then add 20.0g / L cationic organic polymer flocculant E125ml, stir and stand for 15 minutes, then add 1.0g / L auxiliary Coagulant 150ml, total volume about 1L, after stirring, leave standstill for 10 minutes, carry out floc separation by the method for summary of the invention (4), reclaim about 900ml of filtrate, measure filtrate pH value to be 6-7, light transmittance is 96.7%, The turbidity is 5.93 NTU and the surface tension is 61.4 mN / m.

Embodiment 3

[0043] Example 3: Flocculation and separation of single detergent components in main wash preparation wastewater

[0044] Weigh 1.25g of soap according to the method of the content of the invention (2), dissolve it in 700ml of water at 50°C, heat to 70°C, add 1.0g of color bleaching powder, dissolve and keep warm for 15 minutes, add 1ml of polymaleic acid after cooling, and stir for 10 minutes Minutes later, add 5g / L cationic organic polymer flocculant E300ml, a total of about 1L, stir and let stand for 15 minutes, filter with qualitative filter paper, measure the pH of the filtrate to be 6, the light transmittance is 99.0%, and the turbidity is 4.05 NTU, the surface tension is 65.9mN / m; Weigh 2.0g of strong washing powder, dissolve it in 720ml of water, heat to 70°C, add 1.0g of color bleaching powder, dissolve and keep it for 15 minutes, add 0.5ml of polymaleic acid after cooling After stirring for 5 minutes, add 5g / L cationic organic polymer flocculant E280ml, a total of ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com