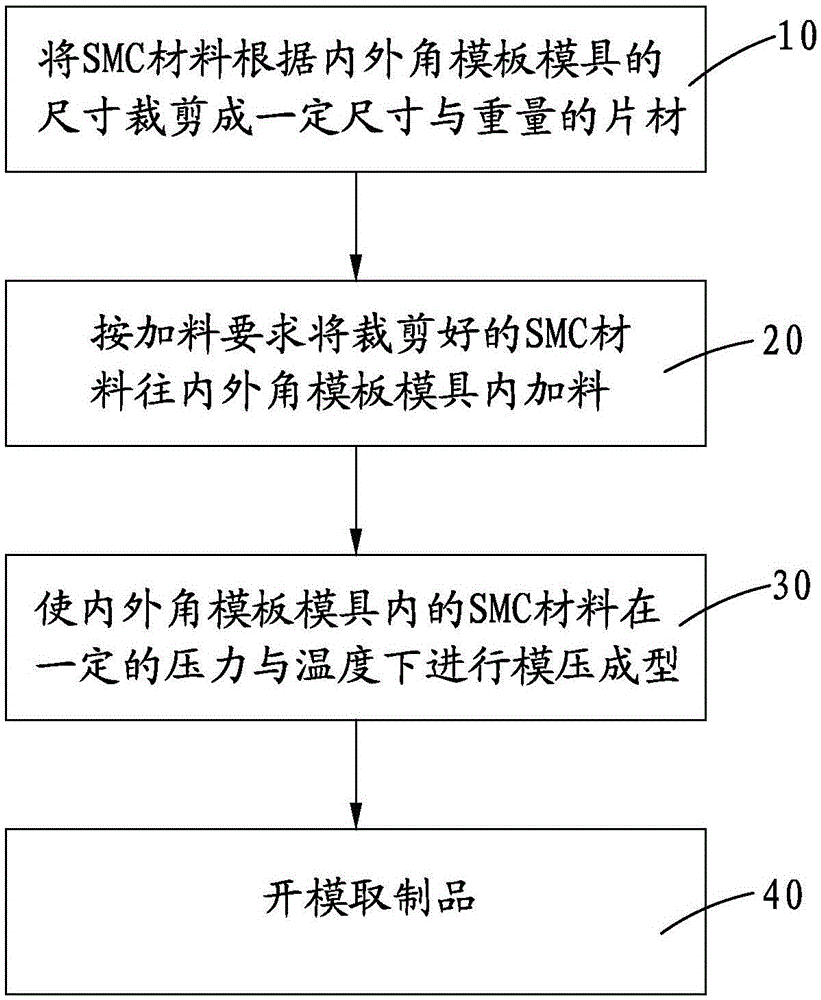

The smc molding process of building inner and outer corner formwork

A technology of molding and corner formwork, applied in the field of manufacturing process of inner and outer corner formwork of buildings, can solve the problems of single material and no significant improvement in performance, and achieve the effects of simple splicing, improved service life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

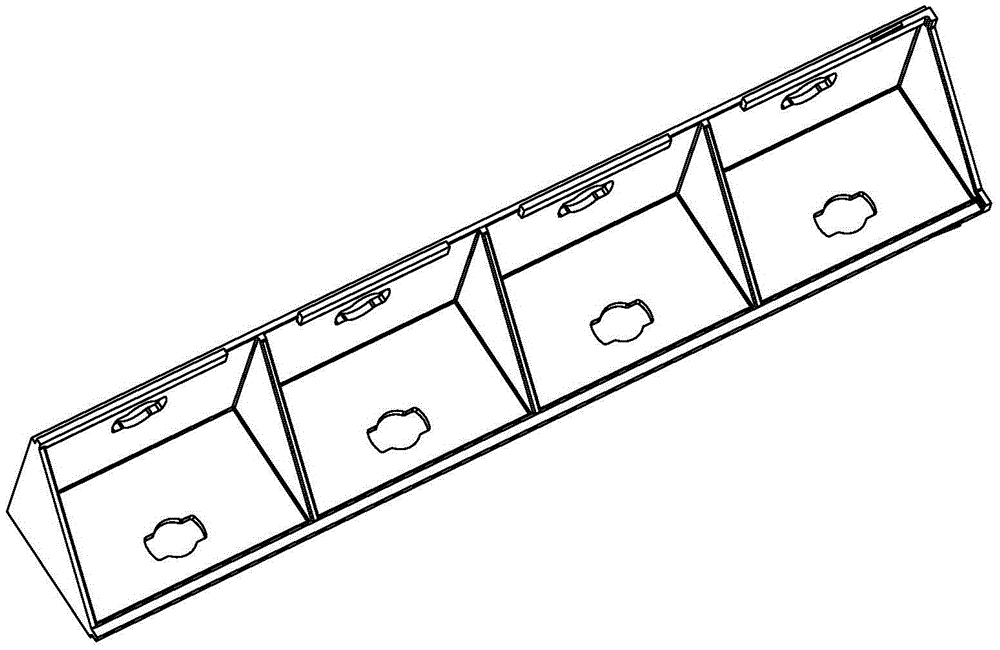

[0031] Such as figure 2 As shown, the size of the molded inner corner formwork of the present embodiment 1-3 is 100mm×600mm×100mm, and the size of the inner corner formwork mold is 102mm×603mm×102mm. Then the cutting size of the SMC material in step 10 is: length 550-600mm, width 90-100mm; weight 1.05-1.23kg.

[0032] Available in 3 SMC materials:

[0033] A. The parameters of the SMC material are as follows: oriented glass fiber contains 30% of the total mass of the SMC material, the molding temperature of the SMC material is 135-150°C, the molding pressure is 80-100bar, and the density is 1.9g / cm 3 , Shrinkage = 0.15%, shrinkage 0 after molding, linear expansion coefficient 1.2×10 -6 / k, heat distortion temperature > 200°C, glass transition temperature 170°C, long-term use temperature 165°C, Young's modulus 12GPa, tensile strength 98MPa, flexural strength 220MPa, flexural modulus 12GPa, impact strength 75KJ / m 2 , oxygen index 27%, water absorption <0.5.

[0034] B. The ...

Embodiment 4-6

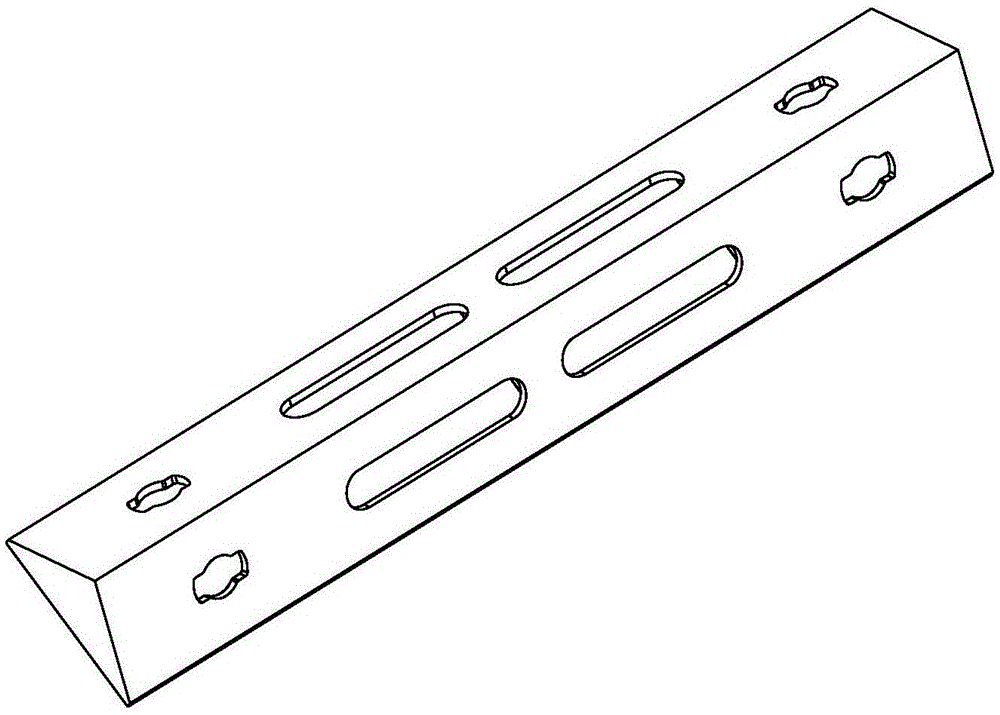

[0040] Such as image 3 As shown, the size of the molded outer corner formwork of Example 4-6 is 80mm×600mm×80mm, and the size of the outer corner formwork mold is 82mm×603mm×82mm. Then the cutting size of the SMC material in step 10 is: length 550-600mm, width 90-100mm; weight 1.05-1.23kg.

[0041] The following table is the parameters with differences in Examples 4-5.

[0042]

[0043] It can be seen that the performance of the inner corner formwork prepared by the above-mentioned Examples 4-6 is greatly improved, and the service life is long, which is beneficial to repeated use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com