Nickel cerium catalyst as well as preparation method and application thereof

A catalyst, nickel-cerium technology, applied in chemical instruments and methods, physical/chemical process catalysts, combustion methods, etc., can solve the problem of low combustion activity of methane, and achieve the effects of low cost, simple preparation steps, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

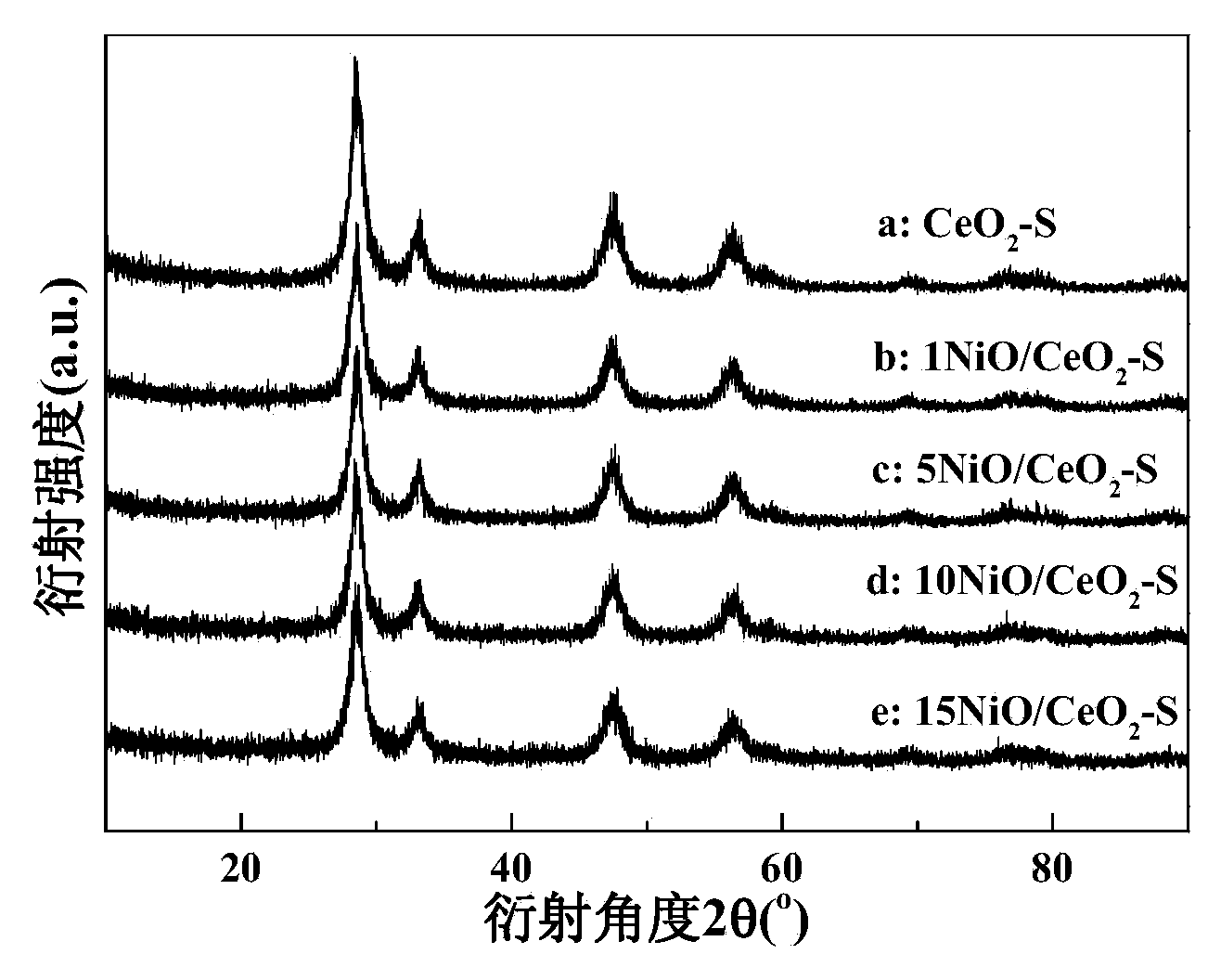

[0024] 1) 3.474g Ce(NO 3 ) 3 ·6H 2 O and 50mL benzyl alcohol (both pure in AR) were added to a 150mL round-bottomed flask, placed in an oil bath, heated to reflux and stirred evenly; when the oil temperature rose to 120°C, open the round-bottomed flask for 10 minutes to remove water After continuing to reflux for 12h, the mixture was cooled to room temperature, centrifuged and washed with ethanol several times, dried at 90°C for 12h, and calcined at 450°C for 2h.

[0025] 2) Using the equal-volume impregnation method, the cerium oxide carrier was impregnated in the ethanol solution of nickel precursor salt compound according to the catalyst ratio (NiO loading was 1mol%) for 12h, then dried at 90°C for 12h, and calcined in air atmosphere at 450°C 2h, the nickel precursor salt compound is Ni(NO 3 ) 2 ·6H 2 O: Grind and press the calcined catalyst, and take 40-80 mesh after sieving, and the prepared catalyst is abbreviated as 1NiO / CeO 2 -S.

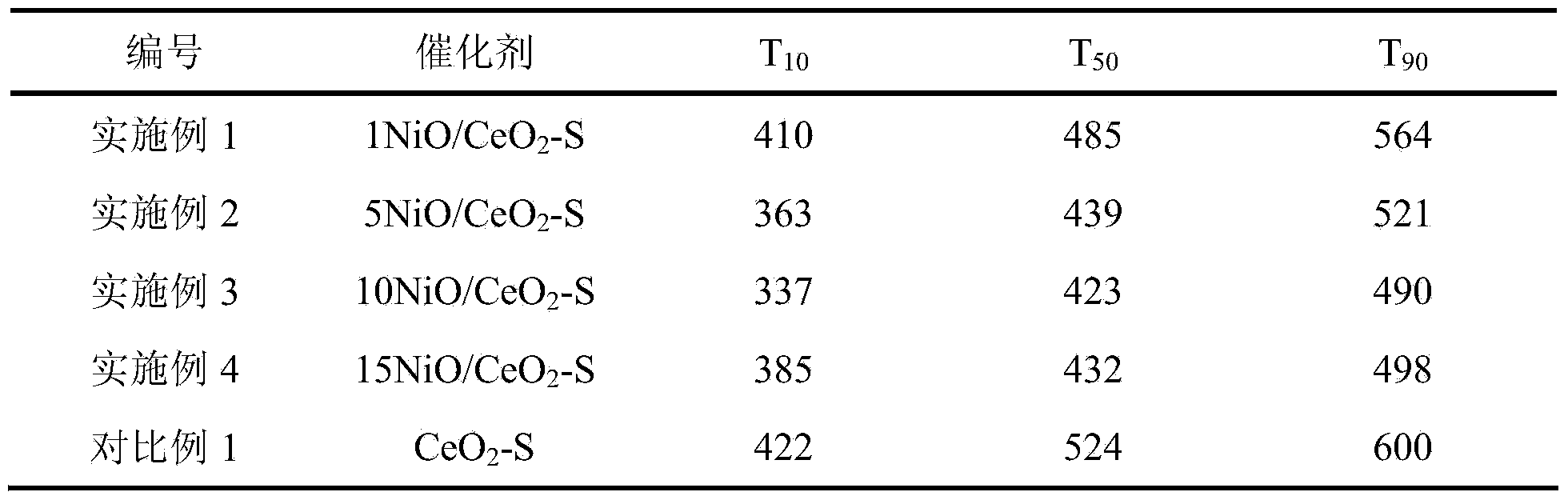

[0026] The activity evaluation...

Embodiment 2

[0028] 1) Same as step 1) in Example 1.

[0029] 2) Change the NiO loading in step 2) of Example 1 to 5mol%, and the rest of the steps are the same as in Example 1, and the resulting catalyst is abbreviated as 5NiO / CeO 2 -S. The activity evaluation results of the catalysts are shown in Table 1.

Embodiment 3

[0031] 1) Same as step 1) in Example 1.

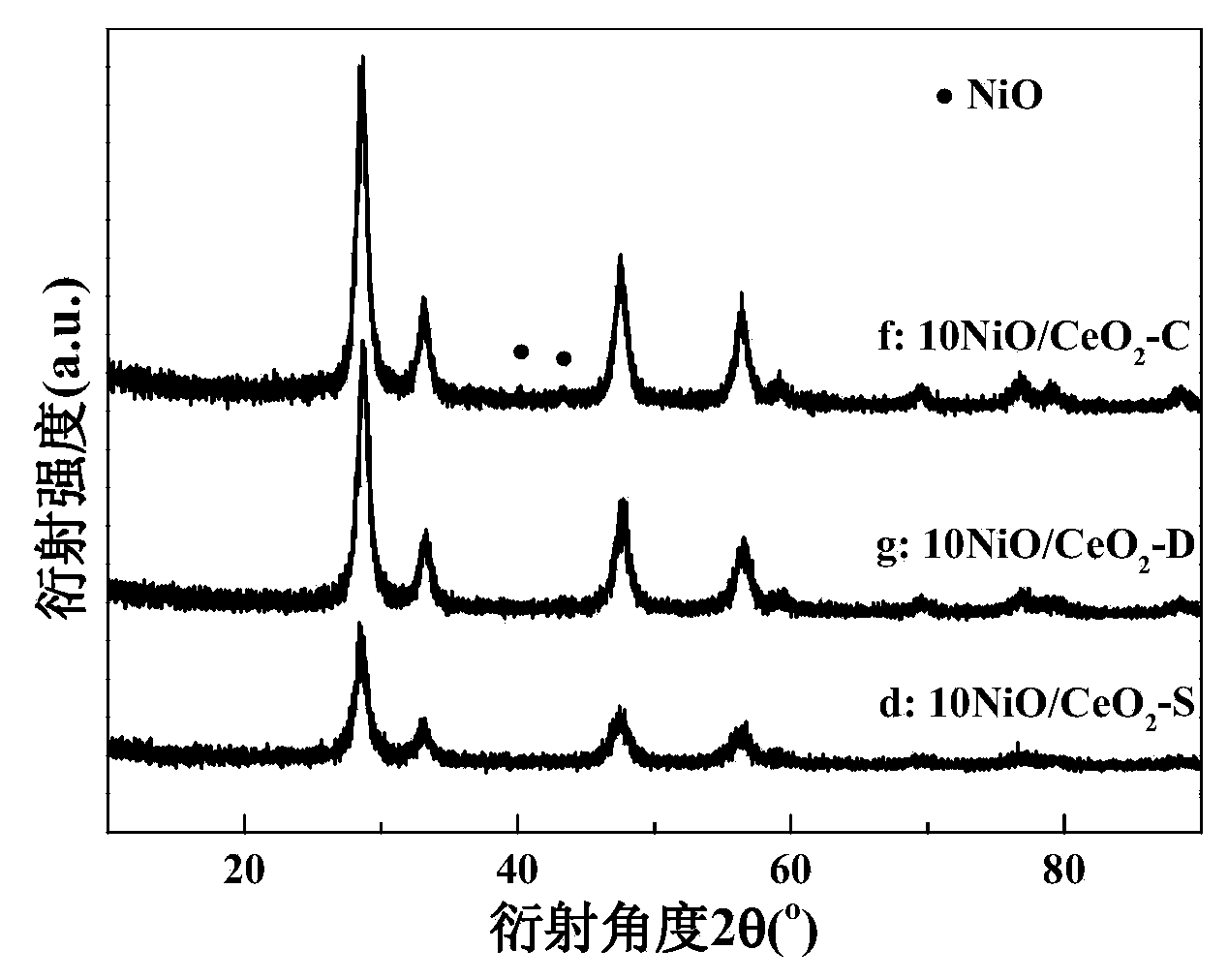

[0032] 2) Change the NiO load in step 2) of Example 1 to 10mol%, and the rest of the steps are the same as in Example 1, and the resulting catalyst is abbreviated as 10NiO / CeO 2 -S. The activity evaluation results of the catalysts are shown in Table 1. Where methane ignition temperature T 10 is 337°C, the half-transformation temperature T 50 is 423°C, the complete conversion temperature T 90 It is 490°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com