Method for catalytic degradation of hexachlorobenzene

A technology of catalytic degradation and hexachlorobenzene, applied in chemical instruments and methods, ammonium halide, organic chemistry, etc., can solve problems such as difficult mass production, low solubility, diffusion, etc., and achieve the effect of large processing capacity and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

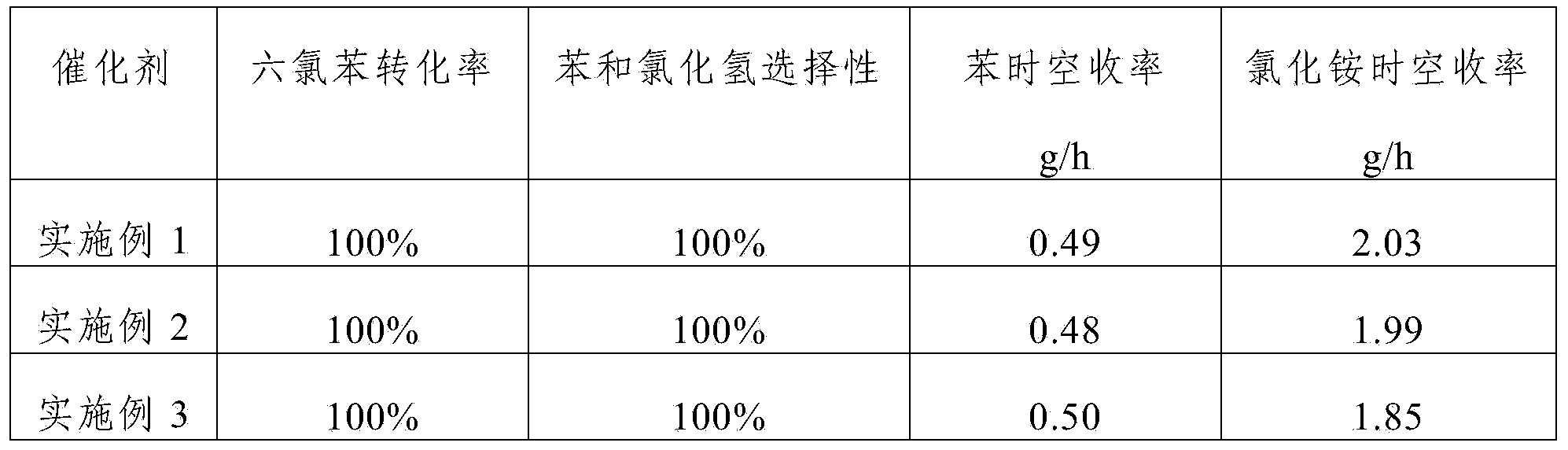

Embodiment 1

[0034] The catalyst of this example includes Al 2 o 3 Carrier, loaded on Al 2 o 3 Active component Pt and auxiliary agent Na on the support; The mass percent composition of active component Pt in the described catalyst is 0.1%, the mass percent composition of auxiliary agent Na is 2.5%; The Al 2 o 3 The carrier is γ-Al 2 o 3 , Al 2 o 3 The particle size of the carrier is 3mm, and the specific surface area is 150m 2 / g.

[0035] The preparation method of catalyst comprises the following steps:

[0036] Step 1, dissolving platinum chloride containing 0.1 g of platinum and sodium chloride containing 2.5 g of sodium in hydrochloric acid with a mass concentration of 5% and mixing uniformly to obtain solution A, adjusting the pH value of solution A to 0.1;

[0037]Step two, 97.4g Al 2 o 3 The carrier is placed in an aqueous citric acid solution with a mass concentration of 0.01%, and soaked at 50°C for 4 hours;

[0038] Step 3, the soaked Al in step 2 2 o 3 The carrie...

Embodiment 2

[0041] The catalyst of this example includes Al 2 o 3 Carrier, loaded on Al 2 o 3 Active component Ru and auxiliary agent Fe on the carrier; the mass percentage of active component in the catalyst is 3%, and the mass percentage of auxiliary agent is 0.01%; the Al 2 o 3 The carrier is γ-Al 2 o 3 , Al 2 o 3 The particle size of the carrier is 0.5mm, and the specific surface area is 280m 2 / g.

[0042] The preparation method of catalyst comprises the following steps:

[0043] Step 1, dissolving ruthenium trichloride containing 3 g of ruthenium and ferric nitrate containing 0.01 g of iron in hydrochloric acid with a mass concentration of 10% and mixing uniformly to obtain solution A, and adjusting the pH value of solution A to 2.0;

[0044] Step two, 96.99g Al 2 o 3 The carrier is placed in an aqueous sodium citrate solution with a mass concentration of 10%, and soaked at 98°C for 0.5h;

[0045] Step 3, the soaked Al in step 2 2 o 3 The carrier was taken out and pla...

Embodiment 3

[0048] The catalyst of this example includes Al 2 o 3 Carrier, loaded on Al 2 o 3 The active component Ag and auxiliary agent Mg on the support; The mass percent composition of active ingredient in the described catalyst is 0.3%, the mass percent composition of auxiliary agent is 0.05%; The Al 2 o 3 The carrier is γ-Al 2 o 3 , Al 2 o 3 The particle size of the carrier is 1mm, and the specific surface area is 200m 2 / g.

[0049] The preparation method of catalyst comprises the following steps:

[0050] Step 1, dissolving silver chloride containing 0.3g of silver and magnesium carbonate containing 0.05g of magnesium in sulfuric acid with a mass concentration of 10% and mixing uniformly to obtain solution A, adjusting the pH value of solution A to 3.0;

[0051] Step two, 99.65g Al 2 o 3 The carrier is placed in an aqueous sodium hydroxide solution with a mass concentration of 5%, and soaked at 90°C for 1 hour;

[0052] Step 3, the soaked Al in step 2 2 o 3 The carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com