Copper sulfate double-effect automatic plate-type vacuum evaporation device

A technology of vacuum evaporation and copper sulfate, applied in the direction of multi-effect evaporation, process efficiency improvement, photography process, etc., can solve the problems of difficult steam source, high operating cost, circulating water, circulating water pollution and steam consumption, etc., and achieve simple operation and cleaning , the effect of device environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

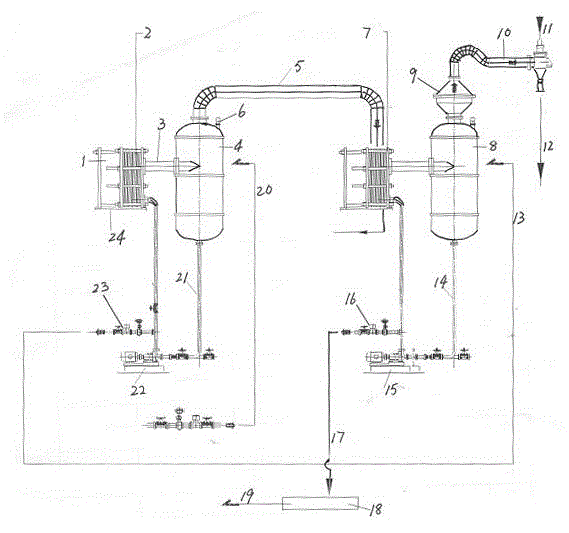

[0012] In conjunction with the accompanying drawings, the description is as follows:

[0013] The structure of the copper sulfate two-effect full-automatic plate vacuum evaporation device of the present invention comprises: a steam inlet pipe, a first-effect heating plate heat exchanger, a vapor-liquid mixture connecting pipe, a first-effect vapor-liquid separation tank, a first-effect secondary steam pipe, a liquid Level meter, second-effect heating plate heat exchanger, second-effect vapor-liquid separation tank, foam catcher, second-effect secondary steam pipe, cooling water inlet pipe, water injector, primary concentrated liquid discharge pipe, second-effect evaporation material-liquid circulation Pipe, two-effect evaporation circulation pump, control valve two, secondary concentrate discharge pipe, semi-open chute, finished product concentrate discharge pipe, copper sulfate stock solution feed pipe, one-effect evaporation feed liquid circulation pipe, one-effect evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com