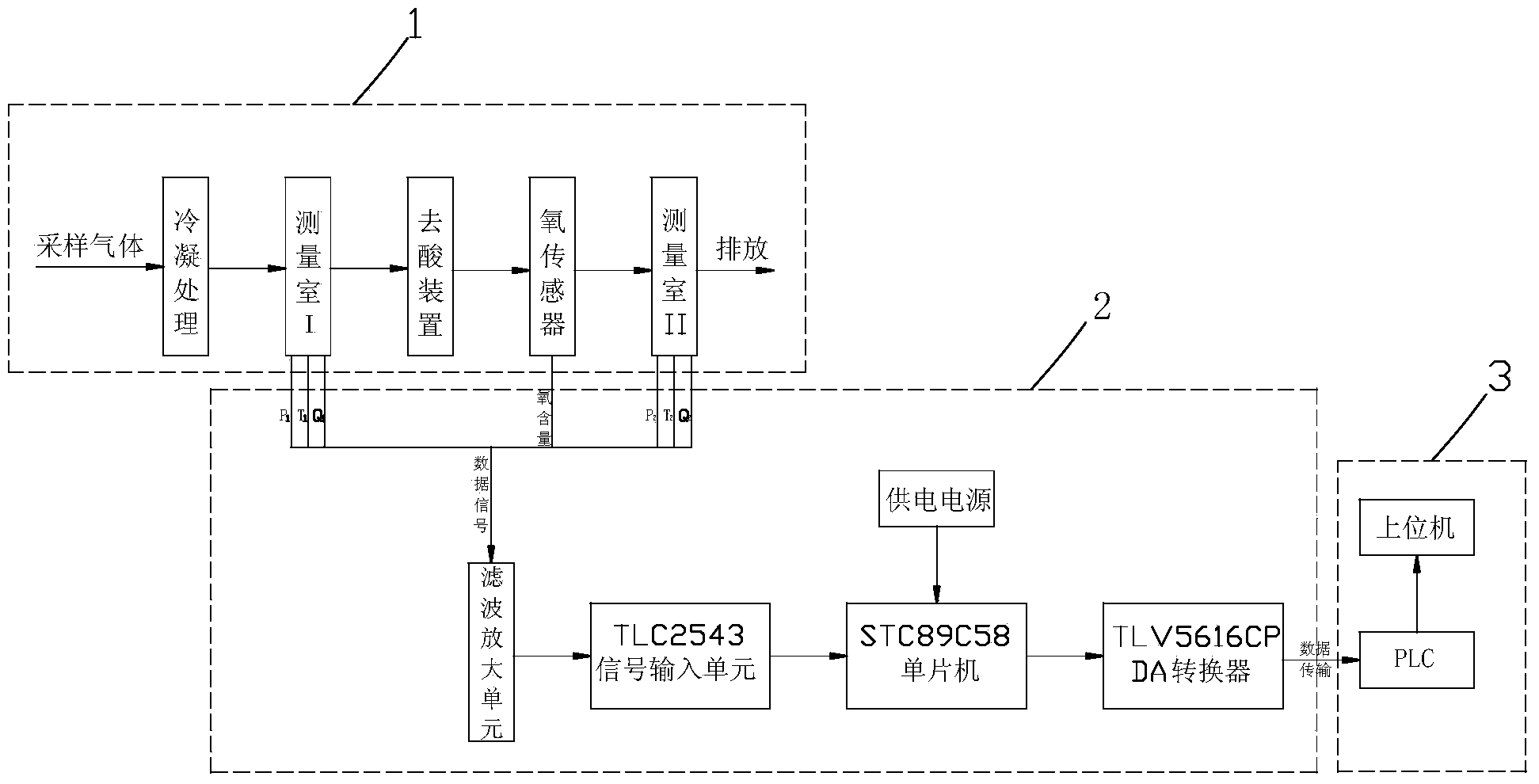

System for monitoring content of residual oxygen in acid regeneration calcinator on line

A technology of residual oxygen content and monitoring system, applied in the direction of material electrochemical variables, chlorine/hydrogen chloride, etc., can solve the problems of incomplete combustion, high cost, high working temperature, etc., to prolong service life, ensure accuracy and stability, and respond short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

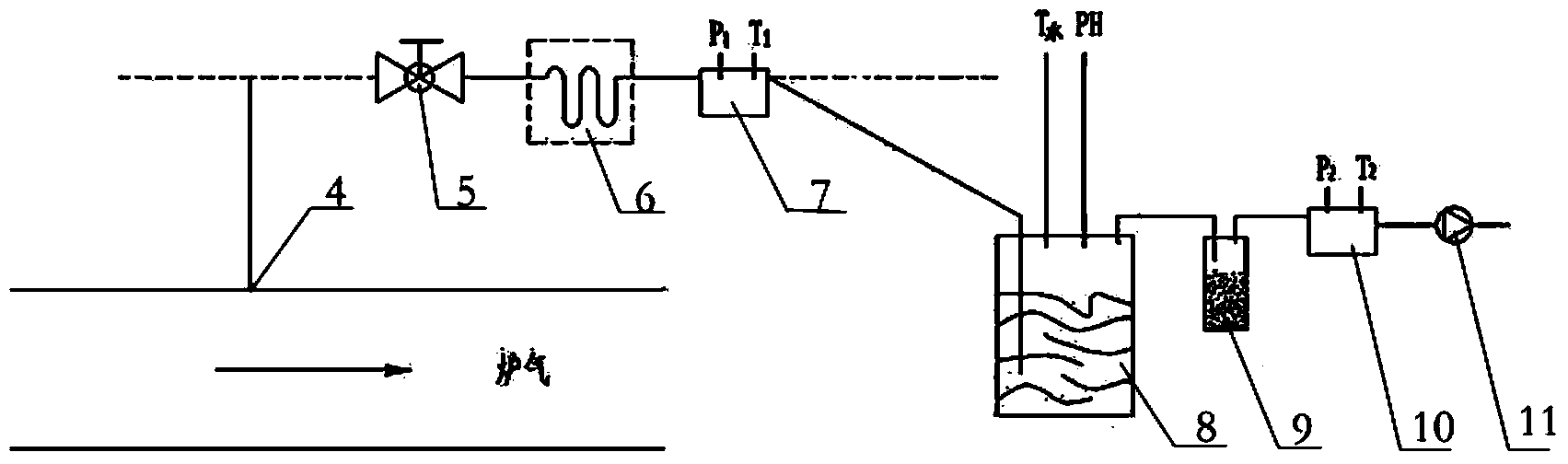

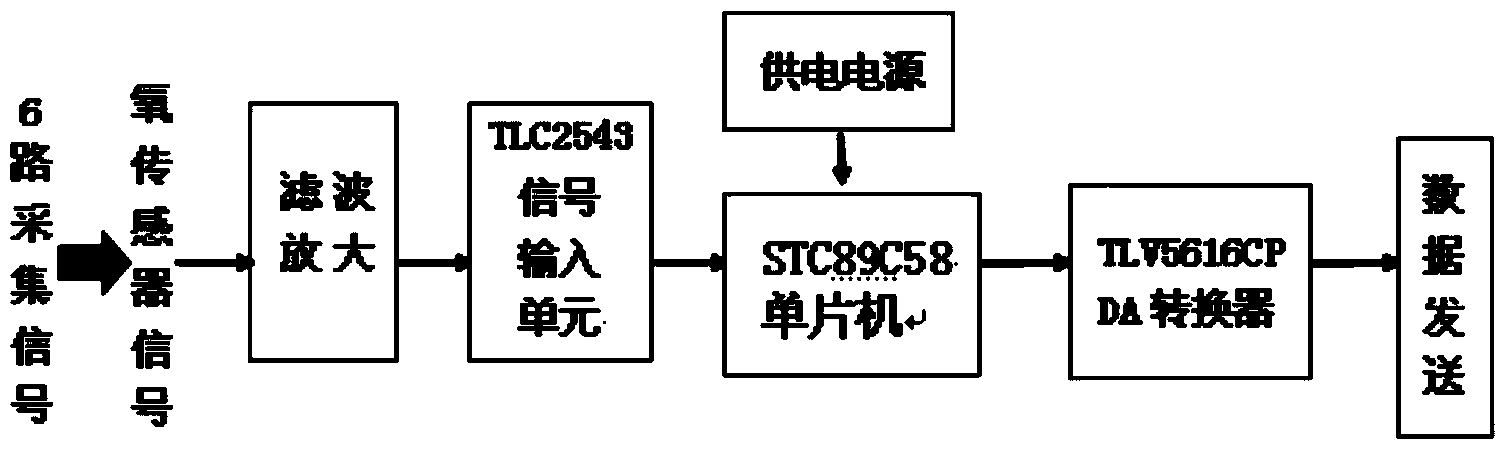

Method used

Image

Examples

Embodiment 1

[0102][Example 1] Using the online monitoring system for the residual oxygen content of the acid regeneration roaster of the present invention, continuous monitoring was carried out for 96 hours at Xinmeida Science and Technology Materials Co., Ltd., Boxing County, Binzhou, Shandong, and the measurement point was at the five-layer roaster of the acid regeneration unit. At the top outlet pipe. The field test results are shown in the table below:

[0103] On-site oxygen content parameter table of Shandong Xinmeida

[0104]

[0105]

Embodiment 2

[0106] [Example 2] Using the online monitoring system for the residual oxygen content of the acid regeneration roaster of the present invention, continuous monitoring was carried out for 72 hours in Tianjin Jianglin Science and Technology Development Co., Ltd., and the measurement point was at the outlet pipe at the top of the five-layer roaster of the acid regeneration unit. The field test results are shown in the table below:

[0107] Tianjin Jianglin site oxygen content parameter table

[0108]

[0109]

[0110] It can be seen from the above data that the oxygen content data range measured by Shandong Xinmeida is between 0.9% and 1.4%, and the oxygen content data range measured by Tianjin Jianglin is between 1.1% and 2.0%.

[0111] The on-line monitoring system for the residual oxygen content of the acid regeneration roaster of the present invention is calibrated experimentally through uniform mixing of nitrogen and oxygen gas, and the accuracy of the oxygen content m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com