Method for testing seawater corrosion of low-alloy steel under stress state

A low-alloy steel, stress state technology, applied in the direction of weather resistance/light resistance/corrosion resistance, using stable tension/pressure test material strength, measuring devices, etc., can solve the problem that there are no identical or similar technical records or literature reports, Can not use seawater natural environment test and other problems to achieve the effect of favorable corrosion research means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

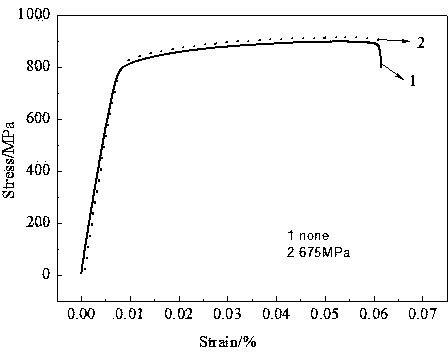

[0025] Choose 316L stainless steel to process the outer support 7 and the inner support 5, and the inner fulcrum 3 and the outer fulcrum 2 adopt Bakelite with a diameter of 5 mm. The test material is TC4, and the size of sample 4 is 2×15×110mm. Clamp the sample 4 between the inner fulcrum 3 and the outer fulcrum 2, insert the tightening rod 8 into the end of the screw micrometer positioning bolt 6, rotate the tightening rod 8 around, so that the spiral micrometer positioning bolt 6 is lifted by 4mm, calculate according to the formula It is obtained that the stress on the sample is 675Mpa. Connect the wires at both ends of the sample 4 to the potential measuring device 9, soak the constant strain loading test device in natural seawater, and start the potential measurement. image 3 It is a comparison chart of stress-strain curves tested in this embodiment.

Embodiment 2

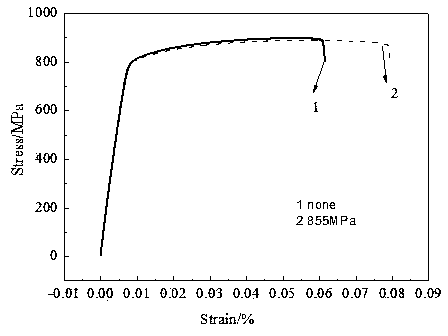

[0027] Choose 316L stainless steel to process the outer support 7 and the inner support 5, and the inner fulcrum 3 and the outer fulcrum 2 adopt Bakelite with a diameter of 5 mm. The test material is TC4, and the size of sample 4 is 2×20×110mm. Clamp the sample 4 between the inner fulcrum 3 and the outer fulcrum 2, insert the tightening rod 8 into the end of the screw micrometer positioning bolt 6, and rotate the tightening rod 8 around to lift the screw micrometer positioning bolt 6 by 6.2mm, according to the formula The calculated stress on the sample is 855Mpa. Install 6 sets of samples 4 under stress state according to the above steps, install 6 sets of constant strain loading devices on the sample holder 10, fix the position with the fixing buckle 12, connect the wires at both ends of the sample 4 to the multi-channel potential detection instrument , place the sample rack 10 in the full immersion area of Qingdao Maidao Seawater Test Station, and start the potential in-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com