Diesel engine test-drive platform circulated water treatment method

A technology of a circulating water system and a treatment method, which is applied in the testing of engines, testing of machinery/structural components, measuring devices, etc., can solve problems such as rainwater microbial pollution, scaling, and corrosion of diesel engine benches, and achieve reliability, reliability, and reliability. The effect of solving the rust and scaling of parts and avoiding the contamination of rainwater and microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

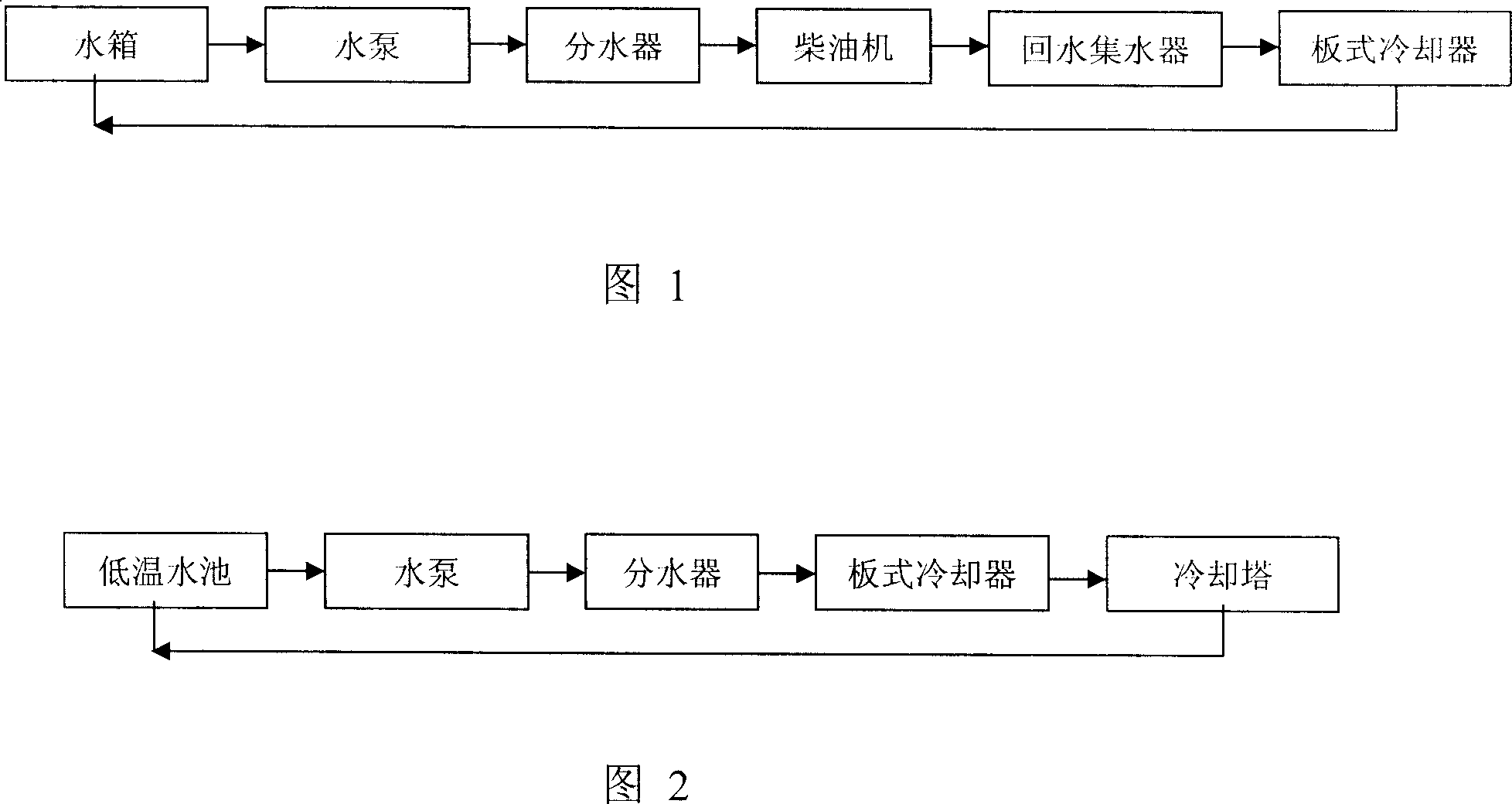

[0015] According to the technical solution of the present invention, the present invention adopts a closed circulating water system to separate the high and low temperature water systems of the diesel engine, and the independent high and low temperature circulating water systems are composed of water tanks, plate coolers, and cooling towers. The process of implementing the cooling water treatment of the diesel engine test run is as follows: firstly, the cooling water circulation system of the diesel engine is washed and pre-filmed to ensure the cleanliness of the cooling water circulation system. Be prepared for the addition of cooling water corrosion inhibitors.

[0016] Add the cooling water corrosion inhibitor provided by Nanjing Ocean Shipping Supply Co., Ltd. to the water tank of the diesel engine cooling water circulation system, according to the requirements for the first use of the water treatment agent: water = 1 (liter): 80 (liter). Measure and control the pH value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com