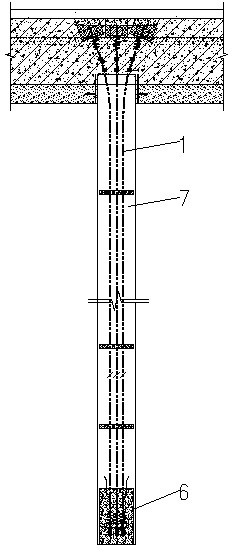

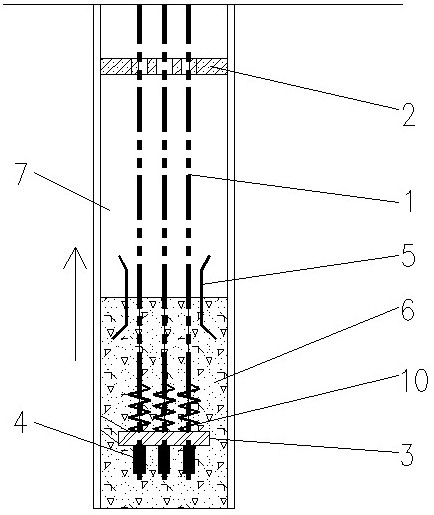

Prestressed anti-corrosion anti-floating anchor rod and construction method

A technology of anti-floating anchor rods and construction methods, which is applied in the direction of basic structure engineering, buildings, sheet pile walls, etc., can solve the problems of reduced tensile bearing capacity, difficulty in waterproofing, and failure of anti-floating components, so as to avoid failure and avoid The effect of being corroded by water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

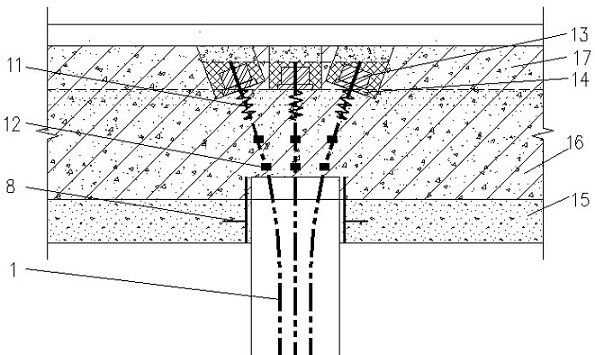

[0033] Embodiment 2, in step c, continue to pour the second column on the first column cast in step a outside the drilled hole, and the second column and the first column are integrally connected through the first water stop ring, Then re-insert the above part into the drilled hole and proceed to step d after additional pouring. All the other are with embodiment 1.

[0034] Different from the prior art, the prestressed anti-corrosion and anti-floating anchor rod and its construction method of the present invention adopt slow bonded prestressed steel strands, and prevent the entire anchor rod from being corroded by water through a new waterproof structure and construction method, and avoid the occurrence of anti-floating anchors. The problem of rod failure, the service life is as long as 50 years or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com