A method for reducing coal consumption and water recovery of coal-fired generating units by using coal drying and exhaust steam

A technology for generator set and coal drying, which is used in drying solid materials, drying, lighting and heating equipment, etc. It can solve the problem of unrecovered water vapor and heat from drying exhaust gas, and achieve the effect of completely controllable oxygen content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

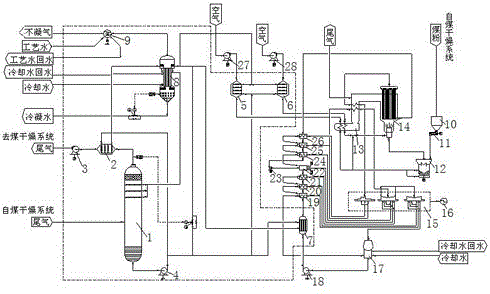

[0030] The technical scheme of the present invention will be further detailed below in conjunction with the accompanying drawings:

[0031] A method for using coal drying exhaust steam to reduce coal consumption and water recovery of coal-fired generator sets is to add a heat and water vapor recovery system between the coal drying system and the coal-fired generator set.

[0032] The dried tail gas (containing a large amount of water vapor, a small amount of non-condensable gas and a small amount of coal dust) from the coal drying system 90~120℃ after dust removal enters the absorption tower 1 (the conventional method is directly discharged into the atmosphere), and the 30~60℃ circulating cooling water is The top spray of the absorption tower 1 and the dry tail gas conduct countercurrent direct contact heat exchange. The large amount of water vapor contained in the dry tail gas is carried by the gas through the absorption tower 1 and converted into hot water, which is condensed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com