Preparation method of surface coating for colored thin film solar cell

A technology of thin-film solar cells and solar cells, applied in coatings, metal material coating processes, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

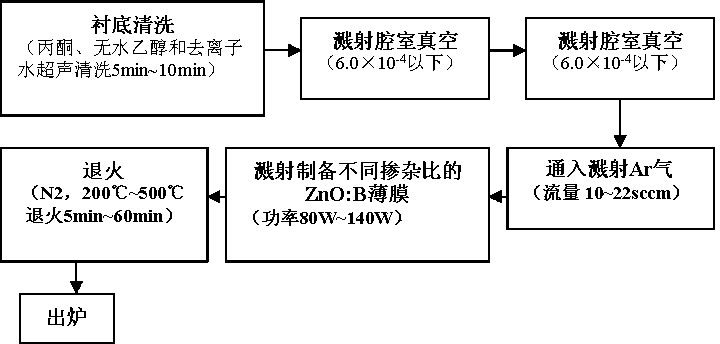

[0021] This embodiment follows the steps:

[0022] Sequentially use acetone, absolute ethanol and deionized water to ultrasonically clean the flat glass substrate for 10min~15min, rinse with absolute ethanol, and blow dry with N2;

[0023] JCP-450 three-target magnetron sputtering coating system is adopted, with a doping concentration of 2%~13%ZnO:B ceramic target as the raw material, and the sputtering gas is Ar gas with a purity of 99.99%;

[0024] The substrate temperature is room temperature~300℃, the background vacuum is 4.0×10-5pa~6.0×10-5pa, the flow rate of Ar gas is 10sccm~22 sccm, the sputtering pressure is adjusted to 0.5pa~1.5pa, and the power is 80w ~140w (0.4~1.2A,

[0025] 66~300V), the sputtering time is 5min~30min, and the ZnO:B thin film is prepared on the substrate by sputtering;

[0026] Put the ZnO:B film sample into the RTP-500 photothermal rapid annealing furnace, and perform rapid annealing at a temperature of 200°C~500°C for 5min~60min under N2 atm...

Embodiment 2

[0029] This embodiment follows the steps:

[0030] Sequentially use acetone, absolute ethanol and deionized water to ultrasonically clean the flat glass substrate for 10-15 minutes, rinse with absolute ethanol, and blow dry with N2;

[0031] The JCP-450 three-target magnetron sputtering coating system is adopted, the ZnO:B ceramic target with a doping concentration of 5%~25% is used as the raw material, and the sputtering gas is Ar gas with a purity of 99.99%;

[0032] The substrate temperature is from room temperature to 300°C, the background vacuum is 4.0×10-5pa~6.0×10-5pa, Ar gas with a purity of 99.999% is introduced, the gas flow is 10sccm~30sccm, and the sputtering pressure is adjusted to 0.5pa~ 1.5pa, the power is 80w~140w (0.4~1.2A, 66~300V), the sputtering time is 10min~30min, and the ZnO:B thin film is prepared on the substrate by sputtering;

[0033] Put the ZnO:B film into the RTP-500 photothermal rapid annealing furnace, and perform rapid annealing at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com