Method for comprehensively recovering valuable metals from copper anode sludge silver separating slag

A copper anode slime and valuable metal technology, applied in the direction of improving process efficiency, can solve problems such as difficulty in comprehensive recovery of valuable metals, and achieve the effects of efficient recovery, high metal recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

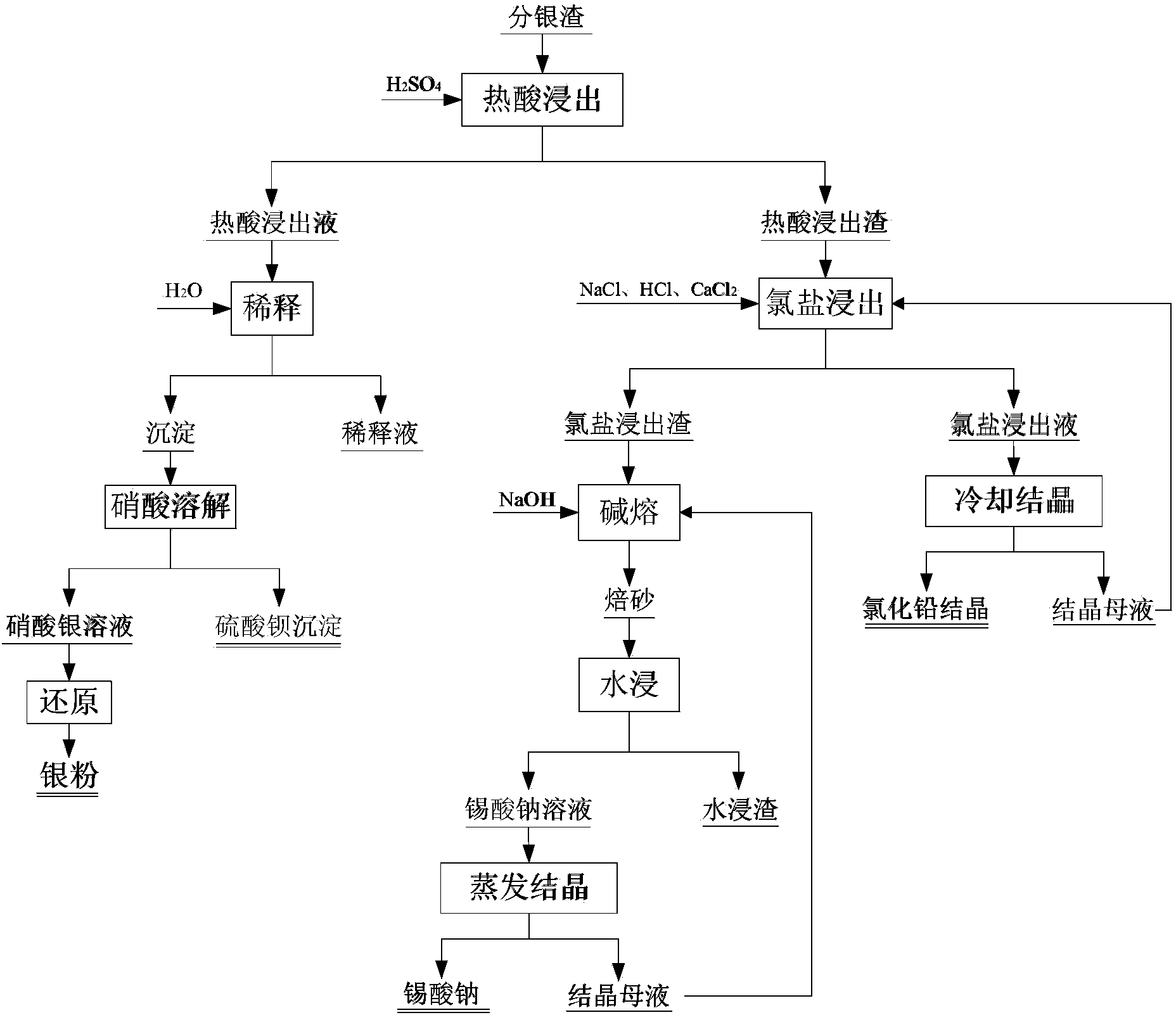

Image

Examples

Embodiment 1

[0021] The main components of the silver separating slag are (%) by weight percentage: Pb16.0, Ag1.86, Sn7.5, Ba31.97.

[0022] Add 750 ml of concentrated sulfuric acid to 500 g of silver-separating slag, and leach for 15 minutes at 350° C. to obtain hot acid leaching solution and hot acid leaching slag.

[0023] The hot acid leaching solution is diluted with 150ml of water, and the diluted solution and precipitate are obtained by filtration; the diluted solution is returned to the copper anode slime pretreatment process, and the precipitate is dissolved with 350ml of 16mol / L nitric acid, and the barium sulfate precipitate and silver nitrate solution are obtained by filtration, and the barium sulfate precipitate is dried. It weighs 263.4g, contains 98.5% barium sulfate, and has a barium recovery rate of 95.5%. The silver nitrate solution is reduced with hydrazine hydrate three times the theoretical value to obtain 8.63g of silver powder, with a purity of 99.5% and a silver reco...

Embodiment 2

[0026] The main components of the silver separating slag are (%) by weight percentage: Pb11.5, Ag5.55, Sn8.5, Ba28.85.

[0027] Add 1000ml of concentrated sulfuric acid to 500g of silver-separating slag, and leaching at 250°C for 25 minutes to obtain hot acid leaching solution and hot acid leaching slag.

[0028] The hot acid leaching solution is diluted with 350ml of water, and the diluted solution and precipitate are obtained by filtration; the diluted solution is returned to the copper anode slime pretreatment process, and the precipitate is dissolved in 500ml of 16mol / L nitric acid, and the barium sulfate precipitate and silver nitrate solution are obtained by filtration, and the barium sulfate precipitate is dried. It weighs 240.5g, contains 98.9% barium sulfate, and has a barium recovery rate of 97.0%. The silver nitrate solution is reduced with hydrazine hydrate 1.5 times the theoretical value to obtain 26.54g of silver powder, with a purity of 99.1% and a silver recover...

Embodiment 3

[0031] The main components of the silver separating slag are (%) by weight percentage: Pb9.78, Ag7.13, Sn10.5, Ba24.95.

[0032] Add 900ml of concentrated sulfuric acid to 500g of silver-separating slag, and leaching at 400°C for 10 minutes to obtain hot acid leaching solution and hot acid leaching slag.

[0033] The hot acid leaching solution is diluted with 300ml of water, and the diluted solution and precipitate are obtained by filtration; the diluted solution is returned to the copper anode slime pretreatment process, and the precipitate is dissolved with 300ml of 16mol / L nitric acid, and the barium sulfate precipitate and silver nitrate solution are obtained by filtration, and the barium sulfate precipitate is dried. It weighs 210.9g, contains 98.7% barium sulfate, and has a barium recovery rate of 98.2%. The silver nitrate solution is reduced with hydrazine hydrate twice the theoretical value to obtain 34.18g of silver powder, with a purity of 99.2% and a silver recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com