Compound type water treatment flocculating agent and preparation method thereof

A water treatment and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of long-term storage instability of polysilicon flocculant, prolonged polysilicic acid gelation time, and unsatisfactory phosphorus removal effect. , to achieve the effect of excellent flocculation performance, low price and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

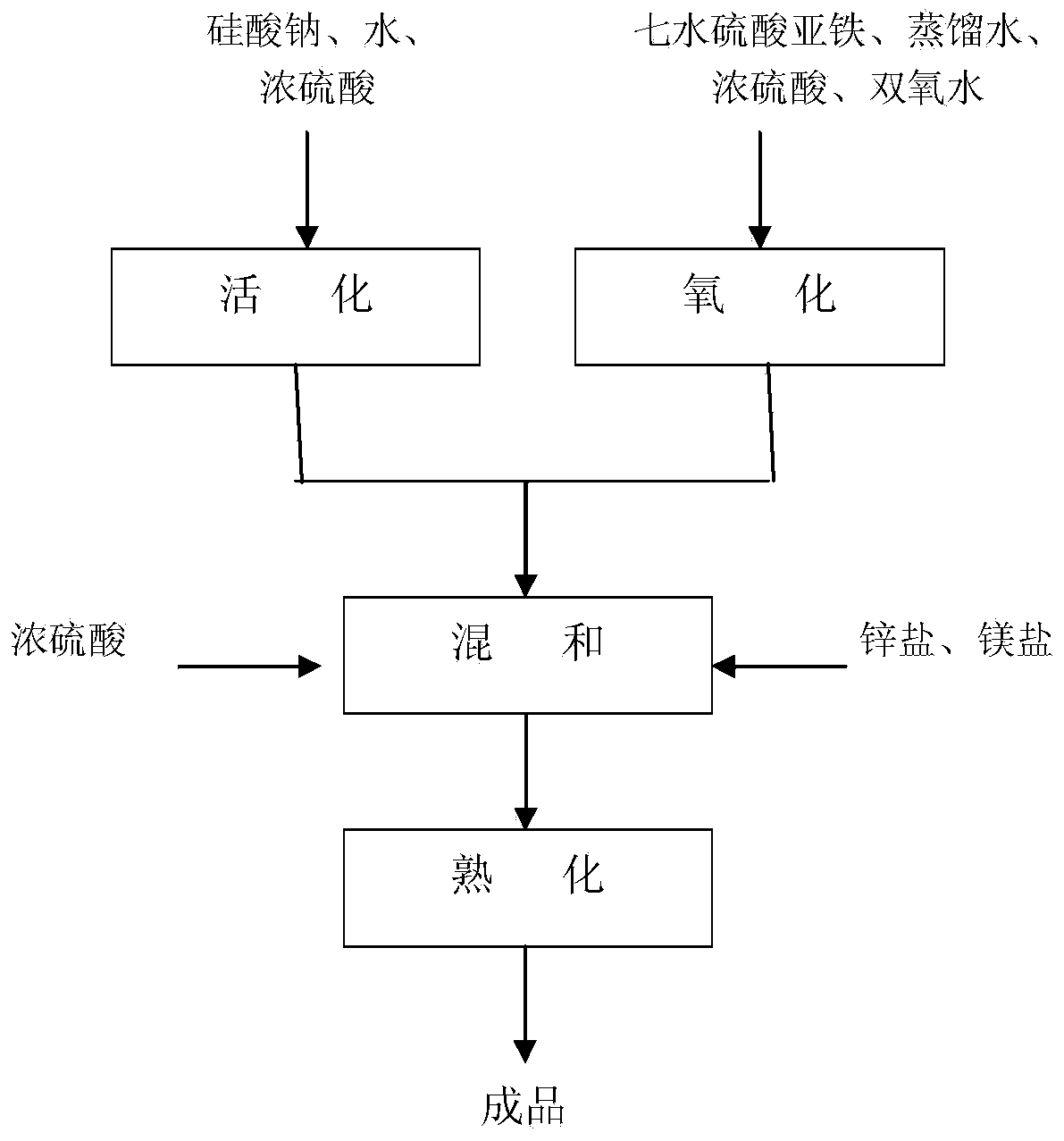

Method used

Image

Examples

Embodiment 1

[0035] Add 18 kg of distilled water to No. 1 reaction tank, start stirring, control the reaction temperature at about 25°C, weigh 6.5 kg of sodium silicate and add it to No. 1 reaction tank, add 2.2 kg of concentrated sulfuric acid, and react for 2 hours to make the silicic acid A certain degree of polymerization is obtained to obtain a semi-finished product A; add 16 kg of distilled water to the No. 2 reaction tank, start stirring, weigh 50 kg of ferrous sulfate and add it to the No. 2 reaction tank, add 1.1 kg of concentrated sulfuric acid, and slowly add 1.2 kg of hydrogen peroxide dropwise To red-yellow-brown, ferrous ions are completely oxidized into ferric ions, and semi-finished product B is obtained; add semi-finished product B to No. 1 reaction tank, start stirring, control the reaction temperature at about 40°C, and add 0.5 kg of zinc sulfate and 0.5 kg of zinc acetate in sequence , 0.5 kg of zinc nitrate, 0.5 kg of magnesium sulfate, 0.5 kg of magnesium chloride, and...

Embodiment 2

[0037] Add 35 kg of distilled water to No. 1 reaction tank, start stirring, control the reaction temperature at about 25°C, weigh 8.0 kg of sodium silicate and add it to No. 1 reaction tank, add 2.0 kg of concentrated sulfuric acid, and react for 2 hours to make the silicic acid A certain degree of polymerization is obtained to obtain a semi-finished product A; Add 20 kg of distilled water to the No. 2 reaction tank, start stirring, weigh 60 kg of ferrous sulfate and add it to the No. 2 reaction tank, add 2.0 kg of concentrated sulfuric acid, and slowly add 1.8 kg of hydrogen peroxide dropwise To red-yellow-brown, ferrous ions are completely oxidized into ferric ions, and semi-finished product B is obtained; add semi-finished product B to No. 1 reaction tank, start stirring, control the reaction temperature at about 40°C, and add 0.7 kg of zinc sulfate and 1.0 kg of zinc acetate in sequence , 1.8 kg of magnesium sulfate, and 1.0 kg of concentrated sulfuric acid to obtain semi-f...

Embodiment 3

[0039]Add 26 kg of distilled water to No. 1 reaction tank, start stirring, control the reaction temperature at about 25°C, weigh 7.2 kg of sodium silicate and add it to No. 1 reaction tank, add 2.8 kg of concentrated sulfuric acid, and react for 2 hours to make the silicic acid A certain degree of polymerization is obtained to obtain a semi-finished product A; Add 22 kg of distilled water to the No. 2 reaction tank, start stirring, weigh 53 kg of ferrous sulfate and add it to the No. 2 reaction tank, add 1.5 kg of concentrated sulfuric acid, and slowly add 1.3 kg of hydrogen peroxide dropwise To red-yellow-brown, ferrous ions are completely oxidized into ferric ions to obtain semi-finished product B; add semi-finished product B to No. 1 reaction tank, start stirring, control the reaction temperature at about 40°C, and add 0.7 kg of zinc sulfate and 0.8 kg of zinc nitrate in sequence , 1.3 kilograms of magnesium chloride, 1.2 kilograms of concentrated sulfuric acid to obtain sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com