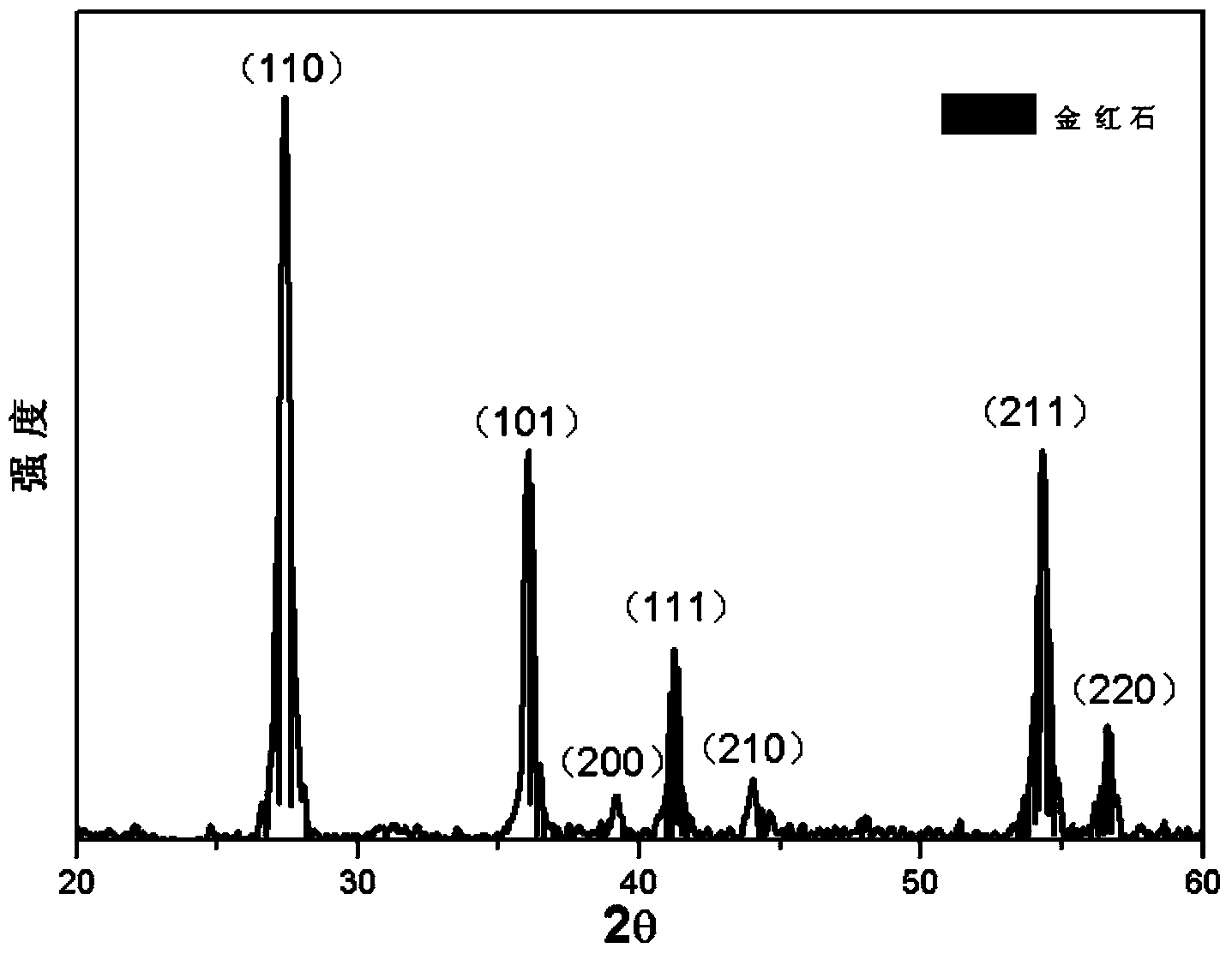

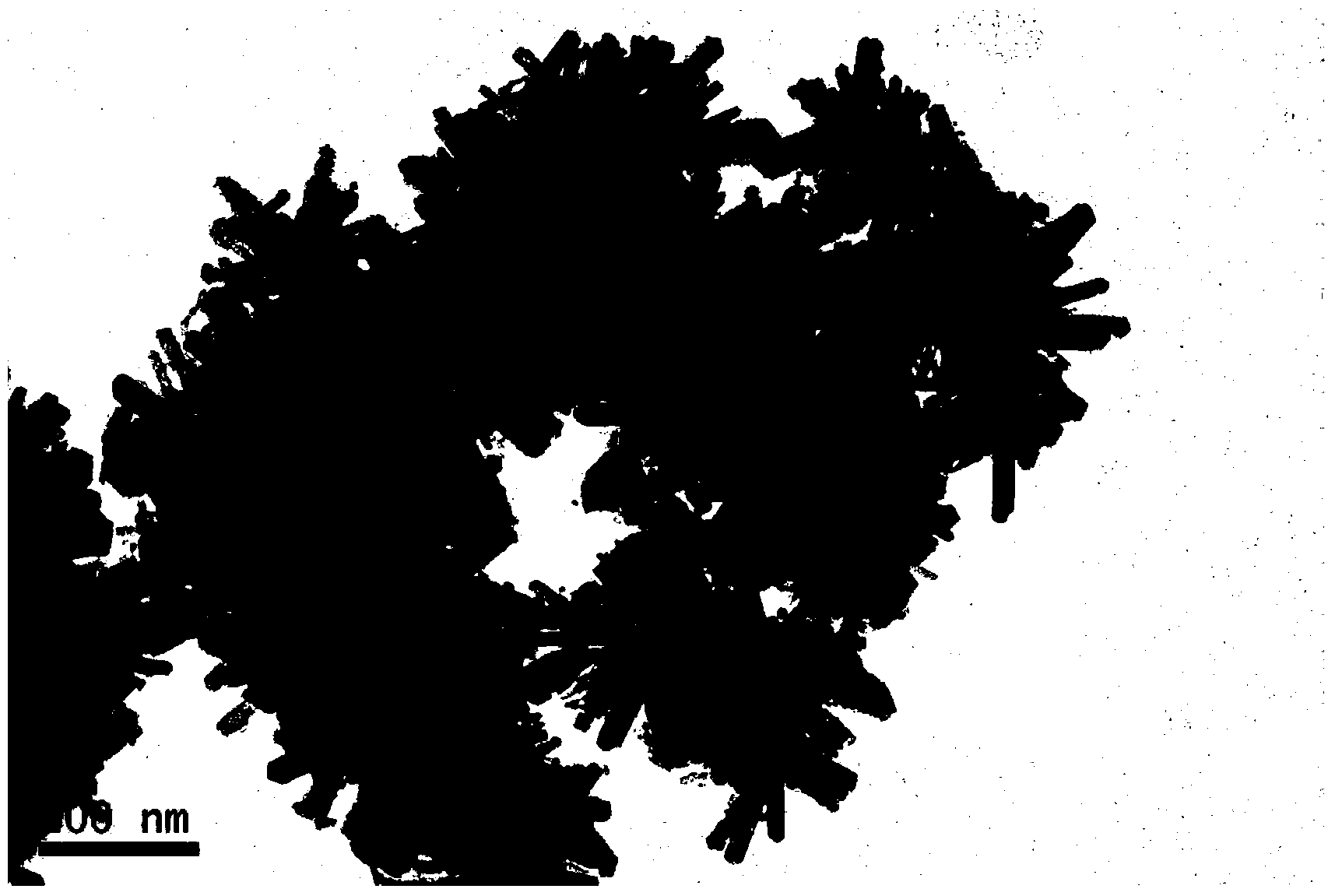

Preparation method of flowery rutile titanium dioxide nanostructure

A titanium dioxide and rutile-type technology, applied in the field of nanomaterials, can solve the problem of large one-time investment and achieve energy saving, avoid high-temperature calcination steps, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of rutile titanium dioxide nano flower structure, characterized in that it comprises the following steps:

[0016] Mix 1ml of titanium tetrachloride, 3mmol of urea, and 2mmol of cetyltrimethylammonium bromide into 30ml of deionized water, stir for 60 minutes, put it into a polytetrafluoroethylene reactor, and place it in an oven at 180°C Insulate for 12 hours, discharge, centrifuge, wash the separated precipitate with alcohol and deionized water alternately for 3 times, and dry at 70°C for 12 hours. The diameter of the obtained product is 200-500nm, and the crystal form is rutile.

Embodiment 2

[0018] A preparation method of rutile titanium dioxide nano flower structure, characterized in that it comprises the following steps:

[0019] Mix 1.5ml of titanium tetrachloride, 4.5mmol of urea, and 3mmol of cetyltrimethylammonium bromide into 45ml of deionized water, stir for 60 minutes, put it into a polytetrafluoroethylene reactor, Keep warm in the oven for 12 hours, discharge, centrifuge, wash the separated precipitate with alcohol and deionized water alternately for 5 times, and dry at 75°C for 13 hours. The diameter of the obtained product is 200-500nm, and the crystal form is rutile. type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com