Special ammonium phosphate salt for abc dry powder fire extinguishing agent and production method thereof

A dry powder fire extinguishing agent and ammonium phosphate technology, which is applied in the field of phosphate, can solve the problems of a great influence on the production of dry powder fire extinguishing agents, an increase in the cost of dry powder production, and a high cost of 1,000 yuan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

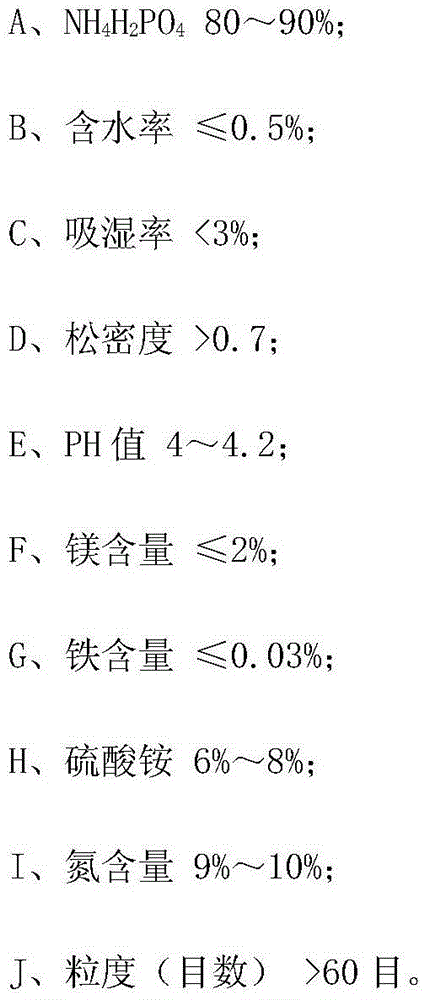

[0013] A kind of special ammonium phosphate salt of ABC dry powder fire extinguishing agent, it is characterized in that, its quality standard is:

[0014]

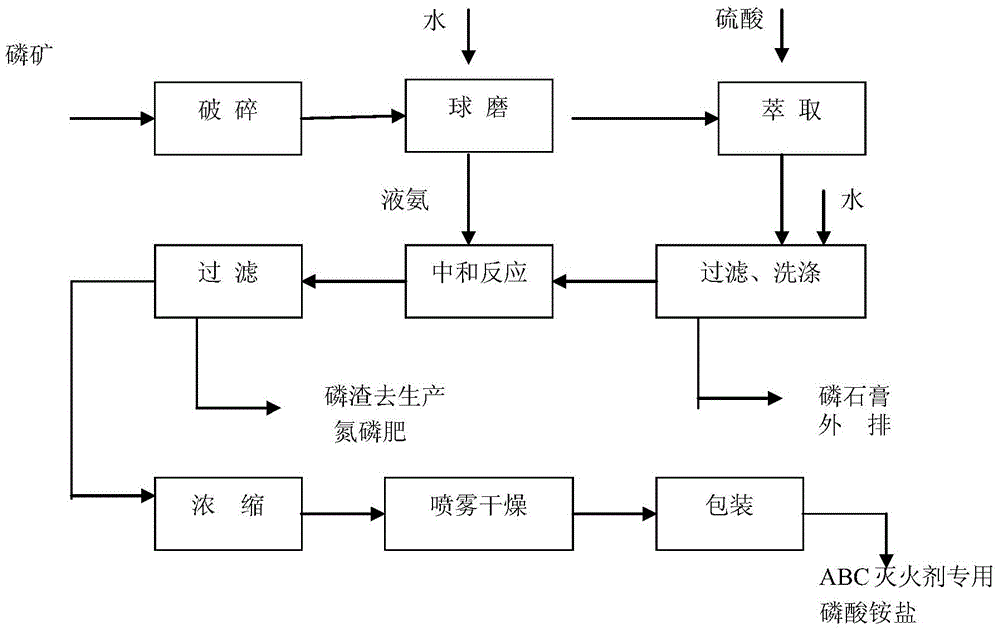

[0015] A kind of method for producing special ammonium phosphate salt of ABC dry powder fire extinguishing agent, comprises the following steps successively:

[0016] E. After the phosphate rock is crushed, add water ball mill;

[0017] F, the material obtained in step A is added to sulfuric acid for extraction, washed, filtered, and concentrated to wet-process phosphoric acid with a concentration of about 25%;

[0018] Add liquid ammonia to the substance obtained in G and B steps for neutralization reaction until the nitrogen content reaches 9% to 10%, and the reaction ends when the pH value is 4 to 4.2;

[0019] H, the material obtained in step C is concentrated and spray-dried to obtain ammonium phosphate special for ABC dry powder fire extinguishing agent.

[0020] The percentages involved in the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com