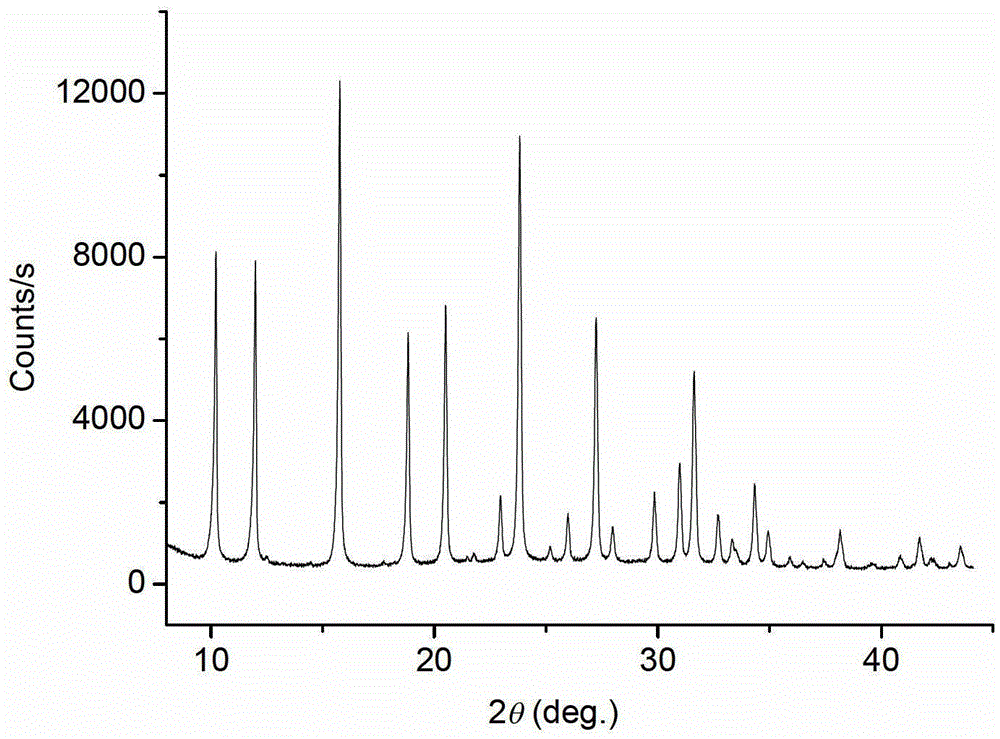

A rare earth ultra-stable Y-type molecular sieve and its preparation method

A molecular sieve and rare earth technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of poor thermal stability and dispersibility, human and environmental toxicity, and poor retention rate, and achieve dispersibility and stability. Good properties, strong conversion of heavy oil and moderate rare earth content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take 500ml of fresh NaY crystallization slurry, and maintain the crystallization slurry temperature at 60°C. Filter and separate the molecular sieve crystallization slurry on a simulated belt filter. When the filter cake is not cracked, wash the molecular sieve filter cake with 300ml of 0.02mol / l (pH 12.3) NaOH solution (50°C), dry it, and record the sample for S-1.

Embodiment 2

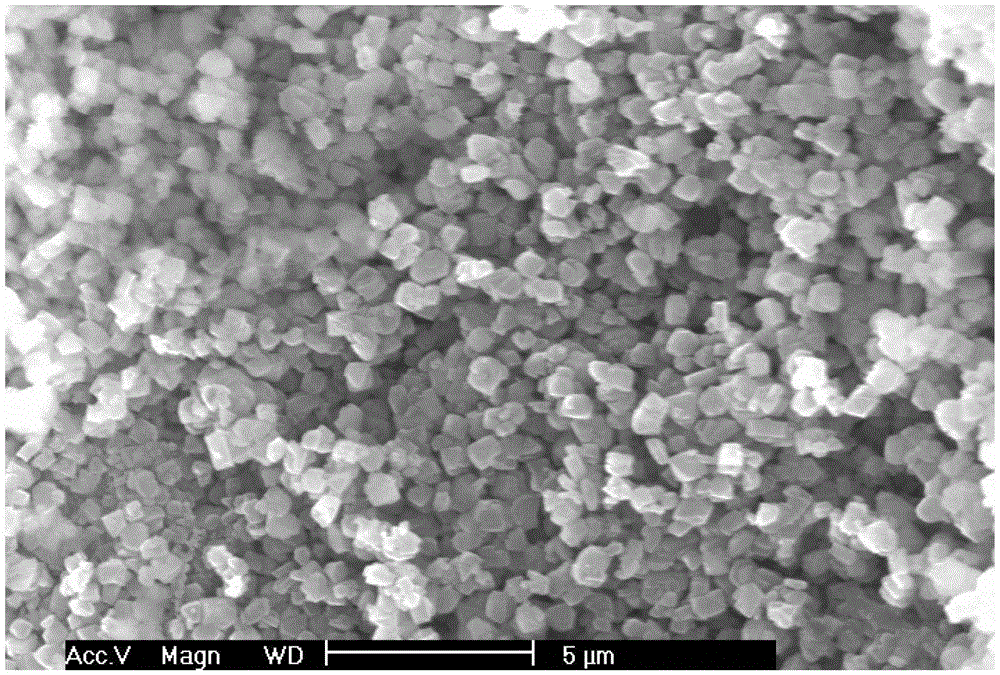

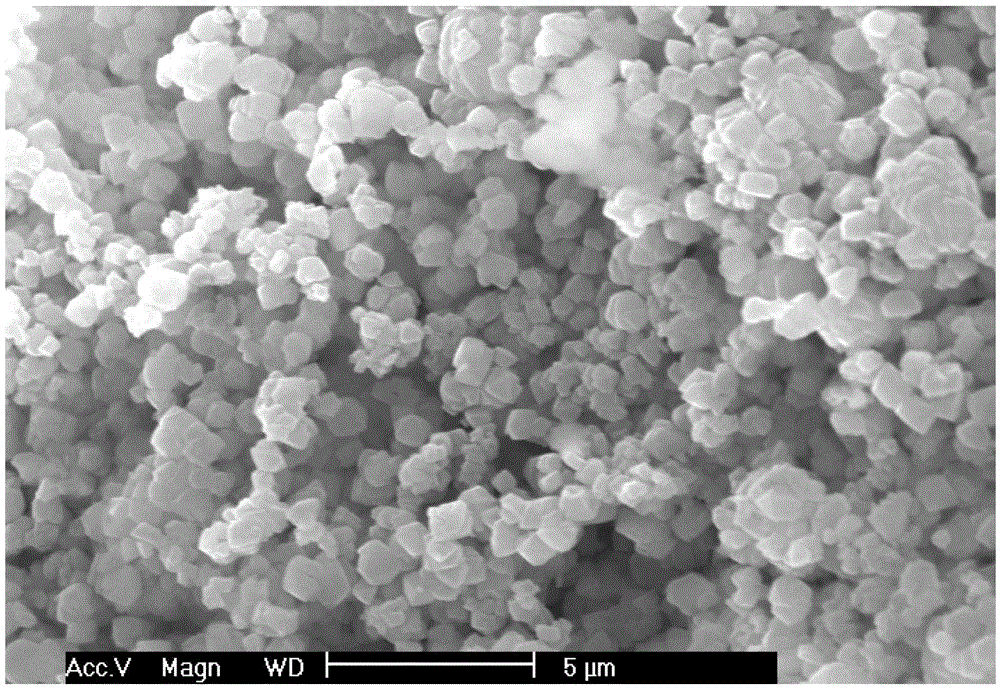

[0061] Using S-1 molecular sieve as raw material, cross-baked RE, H(Na)Y molecular sieve was prepared. The molecular sieve cross-baking process is as follows: at room temperature, use 250g distilled water to beat 50g S-1 molecular sieve (on a dry basis), after the S-1 is evenly dispersed, add 2.1ml dilute hydrochloric acid (13-15wt%), NaY molecular The pH of the slurry was 4.0, and the reaction was carried out at room temperature for 30 min. After the reaction is finished, the molecular sieve slurry is rapidly heated to 95°C, and 6.7ml of lanthanum nitrate solution (La 2 o 3 , 298.2g / l), react at 95°C for 60min. At the end of the reaction, filter and separate the molecular sieve on a simulated belt filter, and when the molecular sieve filter cake is not cracked, add 54ml of 140g / l ammonium chloride solution (90°C) and 250ml of distilled water (90°C) to wash the molecular sieve filter cake . The filter cake was collected and the molecular sieve filter cake was roasted on a ...

Embodiment 3

[0071] Example 3 Using S-1 molecular sieve as raw material, adopting the exchange process of S-2 sample, filtering and separating on a simulated belt filter to obtain RE, NH 4 (Na)Y filter cake. The molecular sieve filter cake was roasted on a rotary furnace, the roasting temperature was 600°C, the residence time of the samples was 120 min., and the roasting atmosphere was 100% water vapor. The sample obtained by roasting is cross-calcined molecular sieve, and the sample is recorded as S-3.

[0072] Table 4: Effects of cross-baking conditions on the physical and chemical properties of molecular sieves

[0073] sample

[0074] Table 4 shows the physical and chemical properties of cross-baked molecular sieves. It can be seen from Table 4 that the use of two-stage temperature-controlled rotary furnace roasting can improve the crystallinity of molecular sieves and reduce the Na in molecular sieves. 2 O content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com