Method for determination of aflatoxin

A technology of aflatoxin and determination method, which is applied in the field of determination of aflatoxin and achieves the effects of high safety, reduced pollution and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Sample extraction: Weigh 10.0346g of edible vegetable oil, add acetonitrile-water extract and stir for 30 minutes, where the volume ratio of acetonitrile and water is 84:16, and then filter with qualitative filter paper.

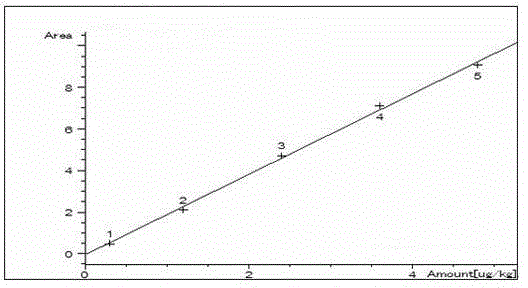

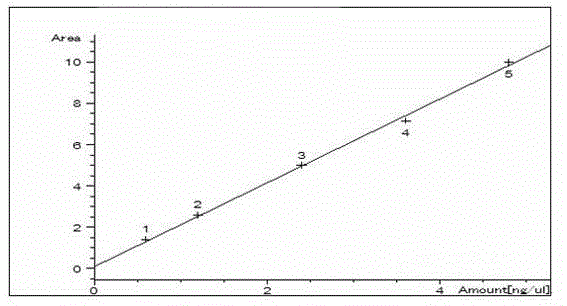

[0028] (2) Determination of standard solution: take aflatoxin B 1 , G 1 Standard stock solution 10μg / mL, dilute to 5mL with acetonitrile, mix well, and store at 2-8°C for three months; when using, acetonitrile is formulated into 0.025μg / mL, 0.05μg / mL, 0.1μg / mL, 0.15μg / mL , 0.2μg / mL, 0.25μg / mL series standard solutions, draw 200μL of each standard series solution, blow dry under nitrogen in a water bath at 60°C, add 200mL n-hexane and 100mL trichloroacetic acid and mix, after 30s, derivatize in a 40°C oven for 15min , put it in a desiccator for 1min at room temperature, dissolve it with 200uL of water-acetonitrile, mix it evenly, and put it into an automatic sampling bottle. figure 2 , the aflatoxin G1 curve is shown in image 3 .

[0029] (3)...

Embodiment 2

[0038] (1) Sample extraction: Weigh 10.1679g corn flour, add acetonitrile-water extract and stir for 30 minutes, where the volume ratio of acetonitrile and water is 84:16, and then filter with qualitative filter paper.

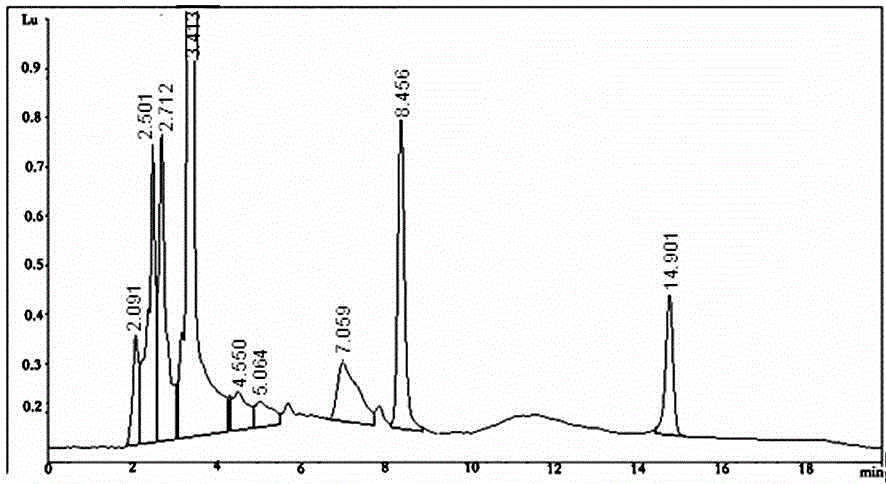

[0039] (2) Sample determination: use high performance liquid chromatography to detect aflatoxin in the sample

[0040] Chromatographic conditions: column: Agilent SB C-18 (25cm×4.6mm); mobile phase: 85% acetonitrile and 15% water by volume; column temperature: 30°C, injection volume: 25mL; flow rate: 1.0mL / min.

[0041] Take 8mL of extraction filtrate to Mycosep TM 228 multifunctional purification column, transfer 2 mL of purification solution into the derivatization bottle in the collection tank of the purification column, after nitrogen blowing at 60 °C, add 200 mL of n-hexane and 100 mL of trichloroacetic acid and mix well, after 30 s, derivatize in a 40 °C oven for 15 min, at room temperature After drying for 1min, dissolve it with 200uL water-acetonitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com