Manufacturing method of high-temperature energy-saving type xonotlite composite heat insulation plate

A technology of xonotlite and its manufacturing method, which is applied in the direction of chemical instruments and methods, thermal insulation, heat exchange equipment, etc., can solve the problems of large equipment investment, large heat energy loss, and poor heat insulation effect, so as to reduce logistics costs and withstand The effect of high temperature and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

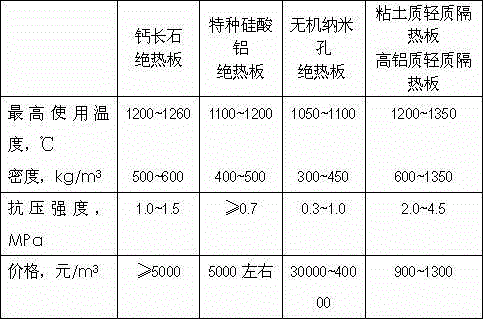

[0026] (1) On a large surface of a 95 mm thick xonotlite thermal insulation board, evenly spray a layer of 810 organic glue, and stick a layer of anorthite thermal insulation board with an equal area of 20 mm thick to form a composite. The overall thickness of the complex is 115 mm. The density of anorthite insulation board is 525 kg / m 3 , the compressive strength is 1.1 MPa, and the heat-resistant temperature is 1200°C. The compressive strength of the xonotlite thermal insulation board used is ≥0.7 MPa.

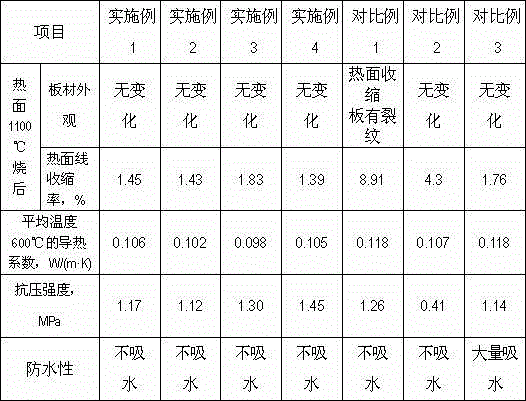

[0027] (2) Evenly spray a layer of 810 adhesive on the outer surface of the composite in step (1), and cover the whole with aluminum foil. After curing, the finished high-temperature and energy-saving xonotlite composite insulation board is obtained. The properties of the plates are shown in Table 2.

Embodiment 2

[0029] (1) Prepare the same complex as in Example 1.

[0030] (2) Mix evenly zirconium silicate powder with a mixture of water glass and water to make a coating. The weight ratio that zirconium silicate powder accounts for the mixture of water glass and water is 20%, and water glass: the weight ratio of water is 0.1.

[0031] (3) Spray evenly a layer of coating obtained in step (2) on the two large surfaces outside the complex obtained in step (1), and let it dry. The amount of spraying is 30 g / m2 as dry powder 2 .

[0032] (4) Evenly spray a layer of 810 adhesive on the outer surface of the composite in step (3), and cover the whole with aluminum foil. After curing, the finished high-temperature and energy-saving xonotlite composite insulation board is obtained. The properties of the plates are shown in Table 2.

Embodiment 3

[0034] (1) On a large surface of a 75 mm thick xonotlite thermal insulation board, evenly spray a layer of silica sol, and stick a layer of 15 mm thick special aluminum silicate thermal insulation board with an equal area, special silicic acid Aluminum insulation panels have a density of 485 kg / m 3 , the compressive strength is 1.3 MPa, and the heat-resistant temperature is 1100°C. The compressive strength of the xonotlite thermal insulation board used is ≥0.7 MPa.

[0035] (2) Mix the mixture of titanium dioxide, water glass and water evenly to form a paint. The weight ratio that titanium dioxide accounts for the mixture of water glass and water is 50%, and water glass: the weight ratio of water is 0.2.

[0036] (3) Spray evenly a layer of the coating obtained in step (2) on the two large surfaces outside the complex obtained in step (1), and dry it. The amount of spraying is 120 g / m2 as dry powder 2 .

[0037] (4) Put the complex in step (3) into an aluminum foil bag, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com