Method for preparing photovoltaic material cuprous sulfide (Cu2S) film

A technology of cuprous sulfide and photovoltaic materials, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of silicon solar cells, environmental pollution, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Substrate cleaning: After cleaning the CdS / ITO substrate with Triton solution, rinse it with deionized water, then ultrasonically clean it in acetone, alcohol, and deionized water for 10 minutes, repeat the above ultrasonic cleaning process 3 times , rinse the substrate with deionized water, dry it with an argon gun, put it in a vacuum drying oven, and set it aside.

[0024] (2) Open the sputtering chamber and place Cu 2 S target material (purity greater than 99.999%), place the substrate in the corresponding position, cover the sputtering chamber, and turn on the mechanical pump to draw the vacuum to below 10 Pa. Then turn on the molecular pump and pump the background vacuum to 7×10 -4 Below Pa.

[0025] (3) Infuse argon gas (> 99.99%) to make the pressure of the sputtering chamber reach 0.5 Pa and keep it for 10 minutes.

[0026] (4) Adjust the power of the DC sputtering source to 90 W, ready for ignition. Pre-sputter for 10 min, clean the surface of the targ...

Embodiment 2

[0030] It is the same as the above-mentioned embodiment 1, except that the step 6 is that the substrate temperature is about 300 oC.

Embodiment 3

[0032] It is the same as the above-mentioned embodiment 1, except that the step 6 is different, and the substrate temperature is about 400 oC.

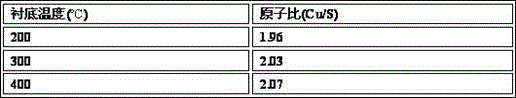

[0033] As shown in Table 1 below, Cu prepared under different substrate temperatures 2 The atomic weight ratio of the S thin film was maintained at Cu / S=2. Basically conforms to Cu 2 Atomic ratio of S.

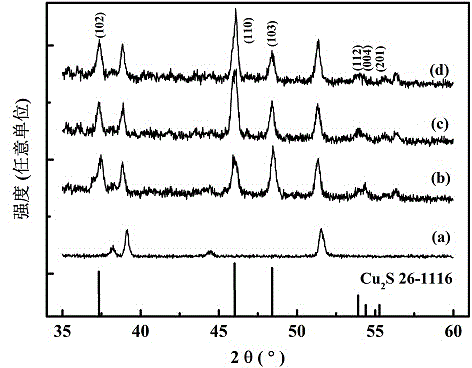

[0034] As shown in the attached picture figure 1 As shown, Cu prepared on CdS / ITO substrate 2 XRD image of S thin film and standard JCPDS card Cu 2 The peak position of S-1116 corresponds, which means that the prepared Cu 2 The S film is a chalcocite structure and belongs to the orthorhombic crystal system.

[0035]

[0036] Table 1 Cu deposition on CdS / ITO substrate at different substrate temperatures 2 Atomic ratio of S thin film (Cu / S)

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com