Strain HD385 producing L-erythrulose through microorganism fermentation, and method

A technology for microbial fermentation and erythrulose, applied in the field of producing erythritol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

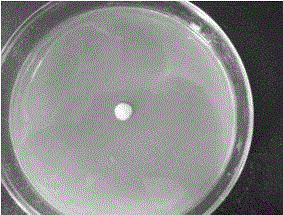

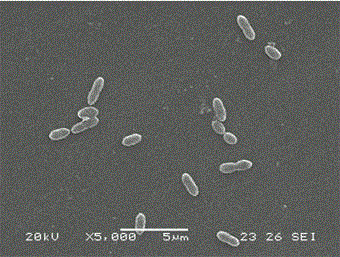

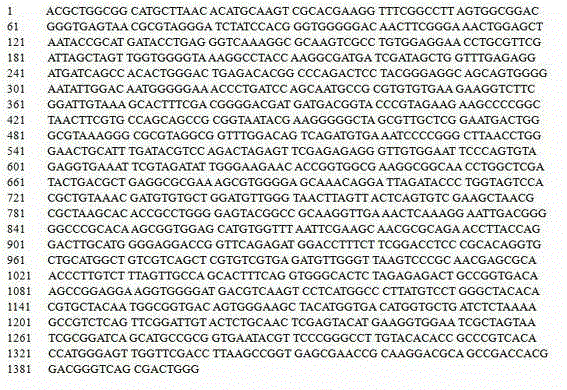

Image

Examples

Embodiment 1

[0042] Utilize described bacterial strain HD385 to ferment the method for erythritol to produce L-erythrulose, be specifically: bacterial strain HD385 is inoculated in first-level seed culture medium (the first-level seed culture medium of described first-level seed culture medium) by the inoculum size of 10% earlier The composition is: erythritol 30 g / L, yeast powder 15 g / L, KH 2 PO 4 0.3 g / L, the balance is water, and the pH is natural), and cultured aerobically at 28°C for 24 h; then the cultured primary seeds were inserted into the secondary seed medium at an inoculation amount of 5% (the secondary The composition of the seed medium is: erythritol 30 g / L, yeast powder 15 g / L, CaCO 3 0.3 g / L, the balance was water, pH 6.0), and after 8 h, the cultivated secondary seeds were respectively inserted into the liquid fermentation medium containing different erythritol concentrations (250 mL triangular bottle, with a liquid capacity of 50 mL). Rotate at 200 rpm, ferment at 28...

Embodiment 2

[0047] The method for producing L-erythrulose by using the bacterial strain HD385 to ferment erythritol is specifically: the bacterial strain HD385 is directly inserted into the liquid fermentation medium according to the inoculum size of 4% (the liquid fermentation medium consists of: food Grade erythritol 100g / L, peptone 8g / L, KH 2 PO 4 3 g / L calcium carbonate, 3 g / L calcium carbonate, water as the balance, medium pH 7), fermented and cultured at 30°C under aerobic conditions for 72 h; the measured L-erythrulose content in the fermentation broth was 79.4 g / L.

Embodiment 3

[0049] The method for producing L-erythrulose by fermenting erythritol using the bacterial strain HD385 is specifically: directly inserting the bacterial strain HD385 into a liquid fermentation medium according to an 8% inoculum size (the liquid fermentation medium consists of: pharmaceutical Grade erythritol 100 g / L, corn steep liquor 20 g / L, KH 2 PO 4 5 g / L calcium carbonate, 8 g / L calcium carbonate, water as the balance, medium pH 5.5), fermented at 30°C for 72 h under aerobic conditions; the measured L-erythrulose content in the fermentation broth was 81.0 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com