Copper slag separation equipment

A technology of separation equipment and separator, applied in magnetic separation, solid separation, grain processing, etc., can solve the problems of flotation tailings index increase, construction difficulty, grinding efficiency reduction, etc., to maintain technical parameters and installation The size remains unchanged, the on-site installation is convenient and simple, and the effect of improving the metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

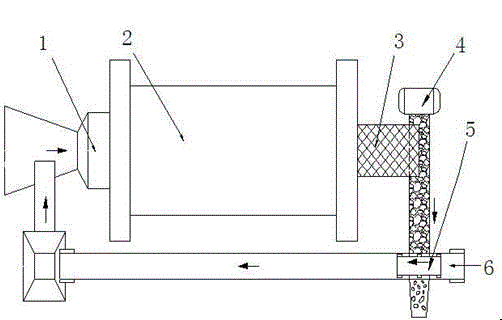

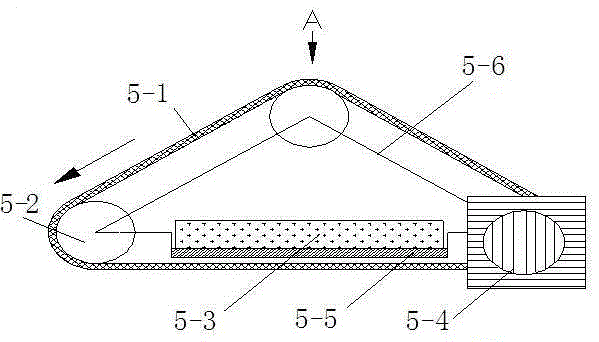

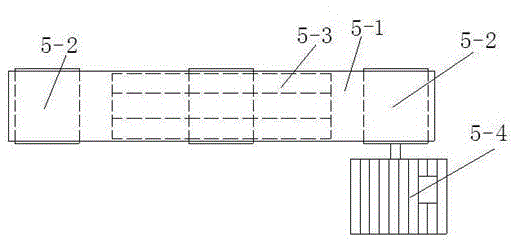

[0020] Embodiment: a kind of slag copper separation equipment (referring to Figure 1-Figure 3 ), it includes a base, the base is respectively connected to the ball mill 2, electric screen 4, slag copper separator 5, ore feeding belt 6 through the bracket, and the two ends of the ball mill 2 are respectively connected to the feed port 1, the cylindrical screen 3, and the cylindrical screen 3 Connect the electric sieve 4, the slag copper separator 5 is arranged on the top of the electric sieve 4, the electric vibrating screen 4 is arranged on the top of the ore feeding belt 6, and the ore feeding belt 6 is connected to the feed port 1. The slag-copper separator 5 comprises a triangular support 5-6, and the three corners of the triangular support 5-6 are respectively connected with 3 rollers 5-2, and the 3 rollers 5-2 are provided with a triangular belt 5-1, and the triangular support 5-6 A tray 5-5 is arranged on the tray 5-5, and a powerful magnet 3 with a magnetic induction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com