Powder antifoaming agent and method for producing same

A powder antifoaming agent and technology for manufacturing method, applied in separation method, chemical instrument and method, foam dispersion/prevention, etc., can solve the problem of unsuitable amount of food additives, and achieve the effect of excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

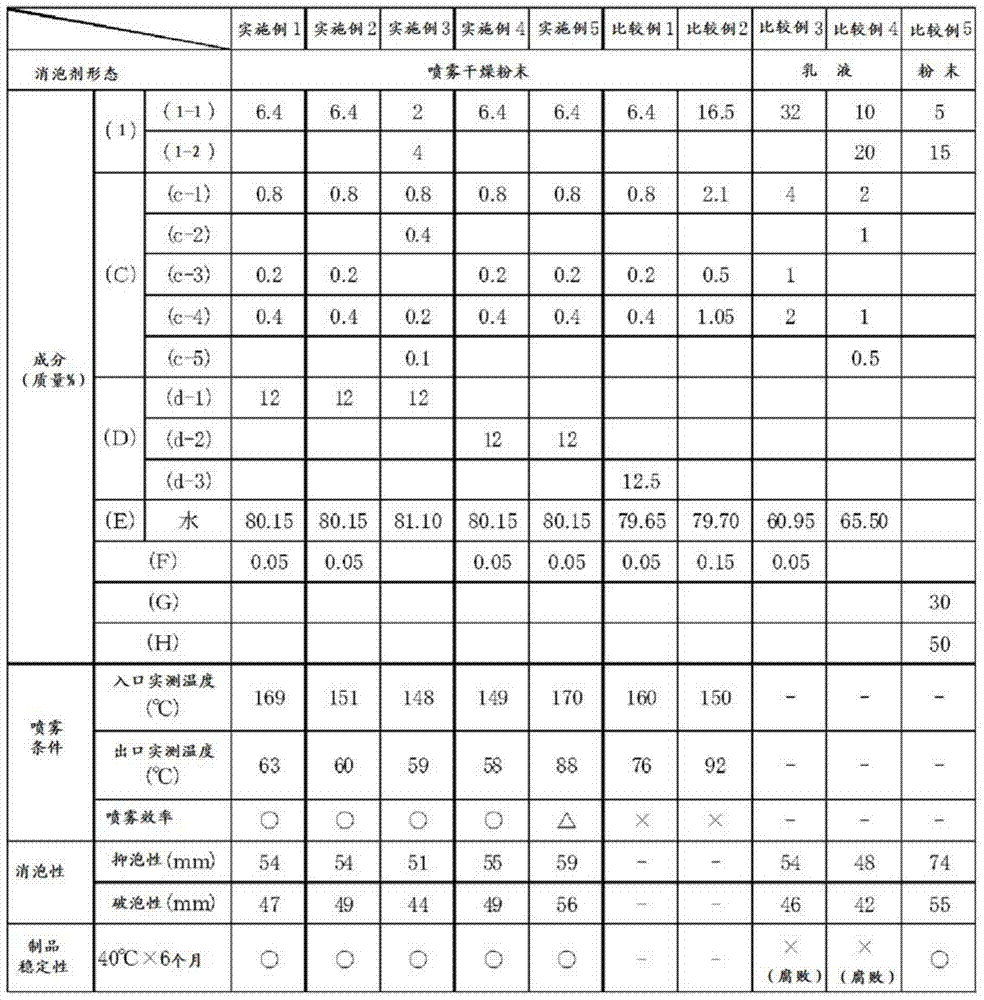

Embodiment 1

[0095] The above-mentioned oil compound (1-a) (6.40% by mass) as the silicone oil compound (1), (c-1) sorbitan monostearate (0.80% by mass) as the surfactant (C) mass %), (c-3) decaglycerol monooleate (0.20 mass %), (c-4) glycerol monostearate (0.40 mass %), as (D) water which is solid at 25°C (d-1) maltodextrin (12.00% by mass) as a soluble encapsulant, sodium carboxymethylcellulose (0.05% by mass) as a thickener (F) and a part of water as (E) are specified by weighing amount, heated to 80°C and uniformly mixed with a homomixer, then slowly added the remaining amount (80.15% by mass) of component (E) water to prepare an emulsion (aqueous dispersion) of the composition shown in Table 1 ( In parentheses is the final composition as an emulsion).

[0096] Next, using this emulsion, spray drying was carried out under the spray conditions shown in Table 1 (drying inlet temperature (actual measurement) 169°C, drying outlet temperature (actual measurement) 63°C) to obtain a powder d...

Embodiment 2

[0098] In Example 1, powder defoaming was obtained under the same conditions as in Example 1 except that the spraying conditions in the spray drying method were changed (drying inlet temperature (actual measurement) 151°C, drying outlet temperature (actual measurement) 60°C) agent.

Embodiment 3

[0100] The above-mentioned oil compounds (1-a) (2.00% by mass) and (1-b) (4.00% by mass) as silicone oil compound (1), (c-1) as (C) surfactant Sorbitan monostearate (0.80 mass%), (c-2) sorbitan monolaurate (0.40 mass%), (c-4) glycerol monostearate (0.20 mass%) , (c-5) sucrose stearate (0.10% by mass), (D) (d-1) maltodextrin (12.00% by mass) which is a solid water-soluble encapsulating agent at 25°C, A part of (E) water was weighed to a predetermined amount, heated to 80°C, and uniformly mixed with a homomixer, and then the remaining amount (81.10% by mass) of component (E) water was slowly added to prepare the composition shown in Table 1 The emulsion (water dispersion) (in brackets is the final composition as the emulsion).

[0101] Next, using this emulsion, spray drying was carried out under the spray conditions shown in Table 1 (drying inlet temperature (actual measurement) 148°C, drying outlet temperature (actual measurement) 59°C) to obtain a powder dispersant foaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com