A solid adsorption air conditioning system driven by automobile waste heat

A solid adsorption, air conditioning system technology, applied in the machine using waste heat, the operation mode of the machine, climate change adaptation and other directions, can solve the problems of poor thermal comfort, increased energy consumption of air conditioning startup, etc., to achieve significant heat exchange effect, Increase energy consumption, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

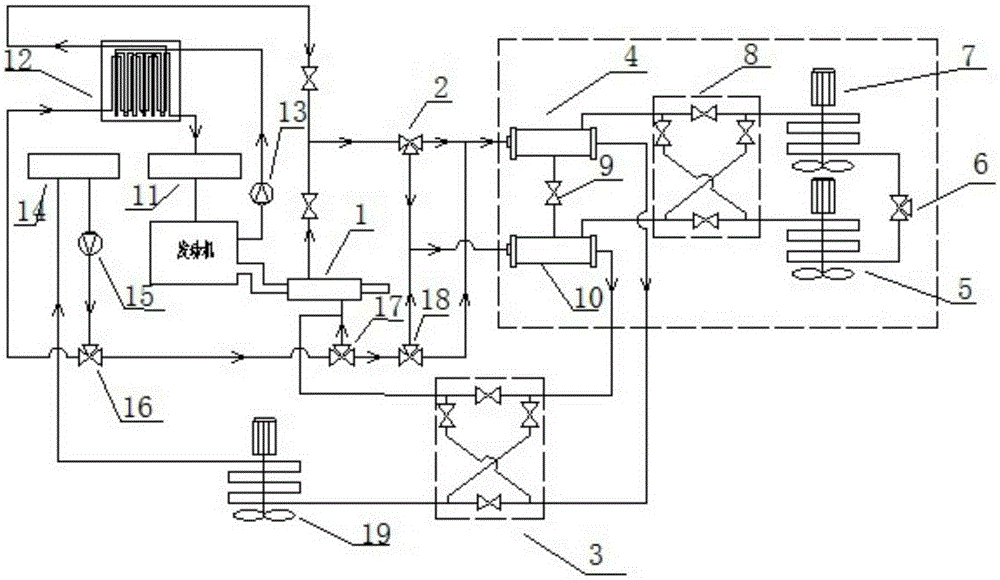

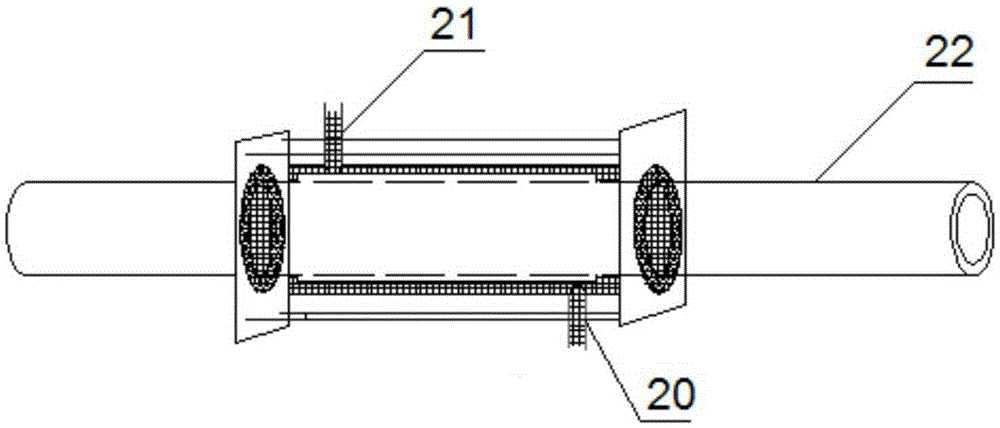

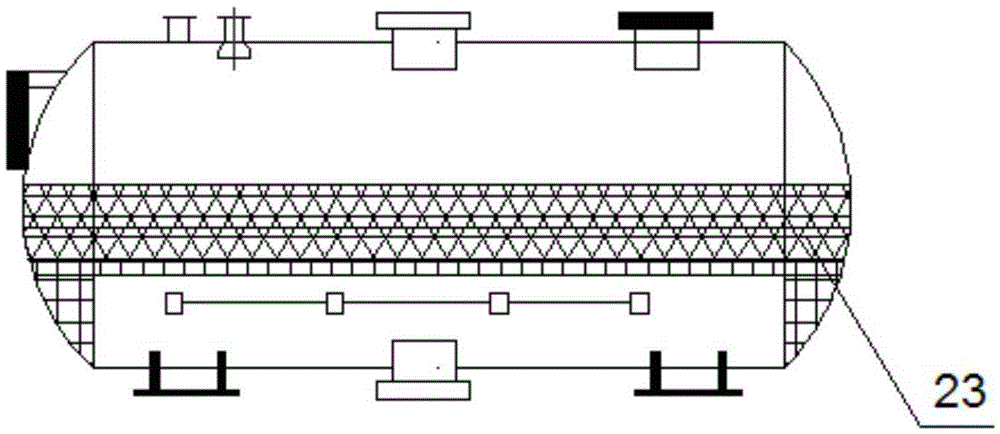

[0023] The system structure of this embodiment is as figure 1 As shown, it includes a heat source circulation preparation system, a continuous mass-regeneration solid adsorption refrigeration and air-conditioning system, a phase change heat storage and heat exchange system, and a circulating water cooling system. The heat source circulation preparation system includes a shell-and-tube heat exchanger 1, a three-way valve a2, and a commutator a3; the continuous mass-regeneration solid adsorption refrigeration system includes an adsorption bed a4, a condenser 5, a throttle valve 6, an evaporation 7, commutator b8, mass transfer pipeline 9 and adsorption bed b10; the adsorption bed a4, condenser 5, throttle valve 6, evaporator 7, adsorption bed b10 and mass transfer pipeline 9 are connected in sequence, wherein commutation The two ends of the device 8 are respectively connected to the adsorption bed a4 and the adsorption bed b10, and the other two ends of the commutator 8 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com