Preparation method of nanoporous nickel block

A nanoporous nickel, block technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex process, long production cycle, high cost, and achieve simple preparation process and equipment. The effect of low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

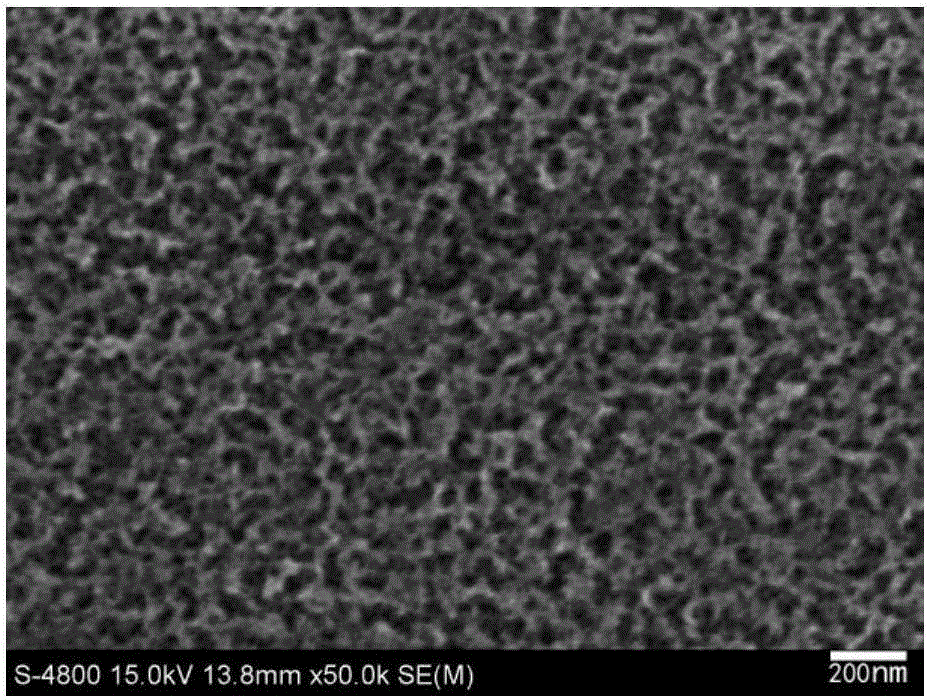

Embodiment 1

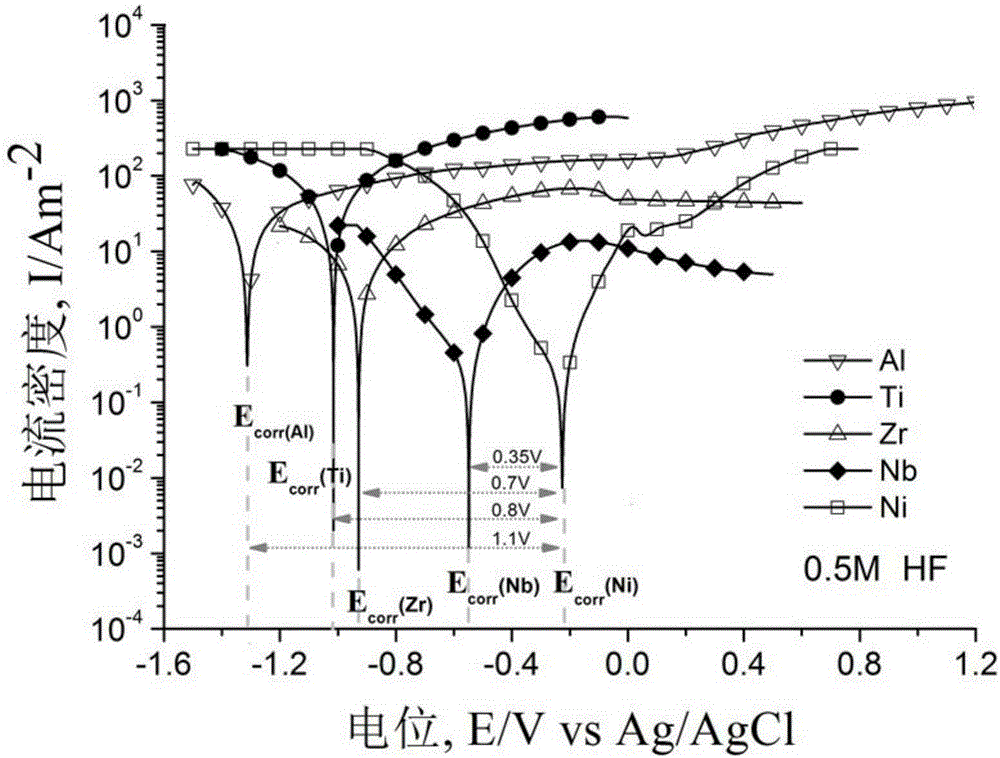

[0031] The first step, the selection of nickel-based amorphous alloy raw materials:

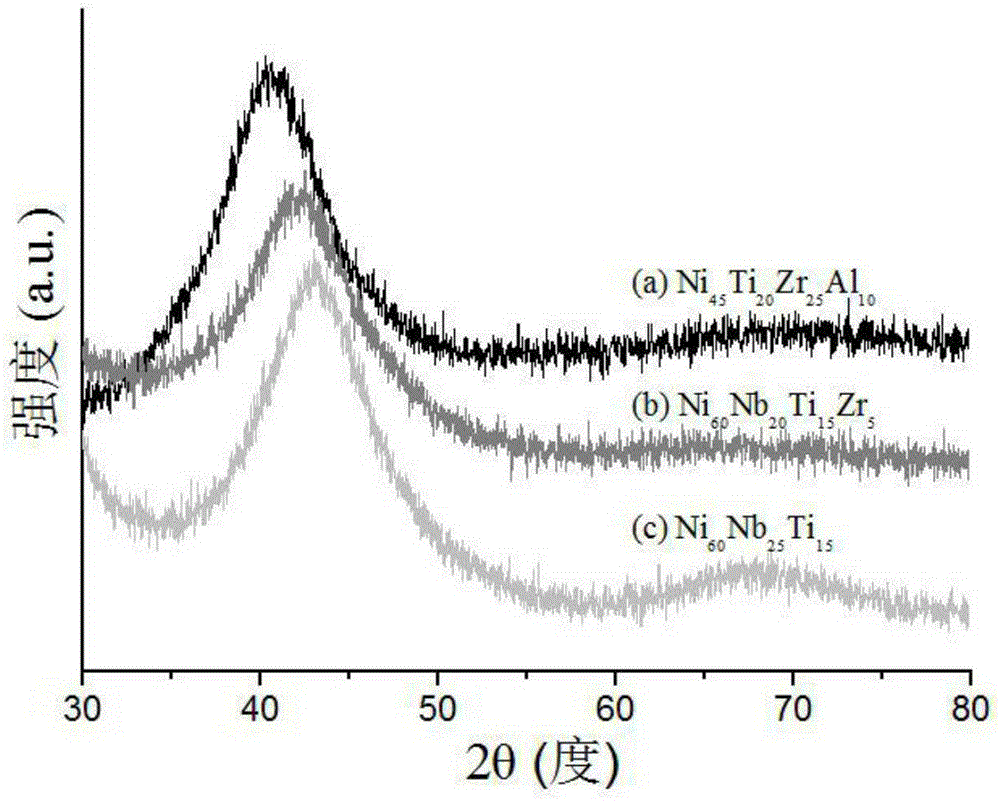

[0032] Select an amorphous alloy with large amorphous formation energy to form a nickel-based amorphous alloy Ni with a maximum thickness of 2mm 45 Ti 20 Zr 25 Al 10 The raw material is the material for preparing the precursor alloy, where the right subscript value of the element symbol is the atomic percentage of the element composition;

[0033] The second step, the preparation of the precursor alloy:

[0034] Put the nickel-based amorphous alloy raw material selected in the first step into a vacuum of 9.0×10 -4 In a vacuum electric arc furnace of Pa, it is heated to a molten state, and an inert gas is introduced to generate a pressure difference of 0.02MPa between the cavity of the vacuum electric arc furnace and the mold, and the molten liquid alloy is sucked into the mold to obtain a thickness of 1mm and a width of 1cm and Ni with a length of 7cm45 Ti 20 Zr 25 Al 10 Nickel-based ...

Embodiment 2

[0042] The first step, the selection of nickel-based amorphous alloy raw materials:

[0043] Select an amorphous alloy with large amorphous formation energy to form a nickel-based amorphous alloy Ni with a maximum thickness of 2mm 60 Nb 20 Ti 15 Zr 5 The raw material is the material for preparing the precursor alloy, where the right subscript value of the element symbol is the atomic percentage of the element composition;

[0044] The second step, the preparation of the precursor alloy:

[0045] Put the nickel-based amorphous alloy raw material selected in the first step into a vacuum of 9.0×10 -4 In a vacuum electric arc furnace of Pa, it is heated to a molten state, and an inert gas is introduced to generate a pressure difference of 0.02MPa between the cavity of the vacuum electric arc furnace and the mold, and the molten liquid alloy is sucked into the mold to obtain a thickness of 1mm and a width of 1cm and Ni with a length of 7cm 60 Nb 20 Ti 15 Zr 5 Nickel-based ...

Embodiment 3

[0051] The first step, the selection of nickel-based amorphous alloy raw materials:

[0052] Choose an amorphous with large amorphous formation energy to form Ni with a maximum thickness of 1.5mm 60 Nb 25 Ti 15 The raw material is the material for preparing the precursor alloy, where the right subscript value of the element symbol is the atomic percentage of the element composition;

[0053] The second step, the preparation of the precursor alloy:

[0054] Put the nickel-based amorphous alloy raw material selected in the first step into a vacuum of 9.0×10 -4 In a vacuum electric arc furnace of Pa, it is heated to a molten state, and an inert gas is introduced to generate a pressure difference of 0.02MPa between the cavity of the vacuum electric arc furnace and the mold, and the molten liquid alloy is sucked into the mold to obtain a thickness of 1mm and a width of 1cm and Ni with a length of 7cm 60 Nb 25 Ti 15 Nickel-based amorphous master alloy sheet;

[0055] The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com