Epoxy curing agent synthesized through mercapto-vinyl addition

An epoxy curing agent, mercaptoethylene technology, applied in organic chemistry, sulfide preparation and other directions, can solve the problems of difficult curing, poor leveling, easy to form salt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

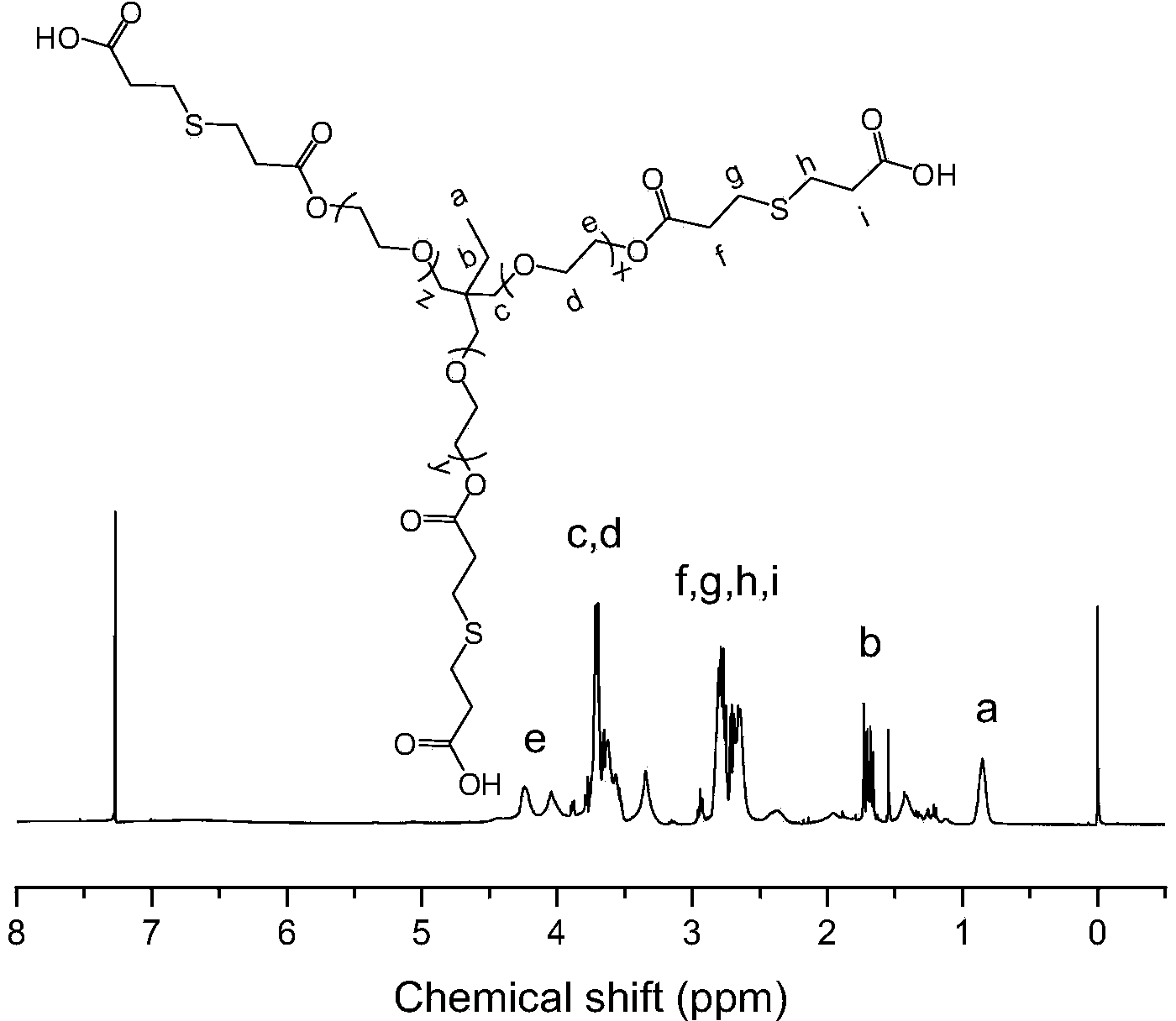

[0020] In a three-necked flask with a stirring device and a thermometer, add 50.5 parts of ethoxytrimethylolpropane triacrylate, 38.5 parts of 3-mercaptopropionic acid, and 1 part of azobisisobutyronitrile. Stirring was started, and the temperature was raised to 70° C. under nitrogen bubbling, reacted for 8 hours, cooled and discharged. The resulting product was a colorless, clear, viscous liquid. Since this product has three active carboxyl groups, it can be used as a curing agent for epoxy resins. The H NMR spectrum of the product was tested with an NMR instrument ( 1 HNMR) such as figure 1 , showing the obvious proton signal of propyl sulfide (2.55-2.88ppm), at the same time, the C=C double bond peak at 5.81-6.22ppm has completely disappeared, indicating that the C=C unsaturated double bond has been completely converted to carboxyl. In addition, after mixing 1.275g of the product with 1.000g of bisphenol A epoxy resin (E-51), the reaction performance of the mixture was ...

Embodiment 2

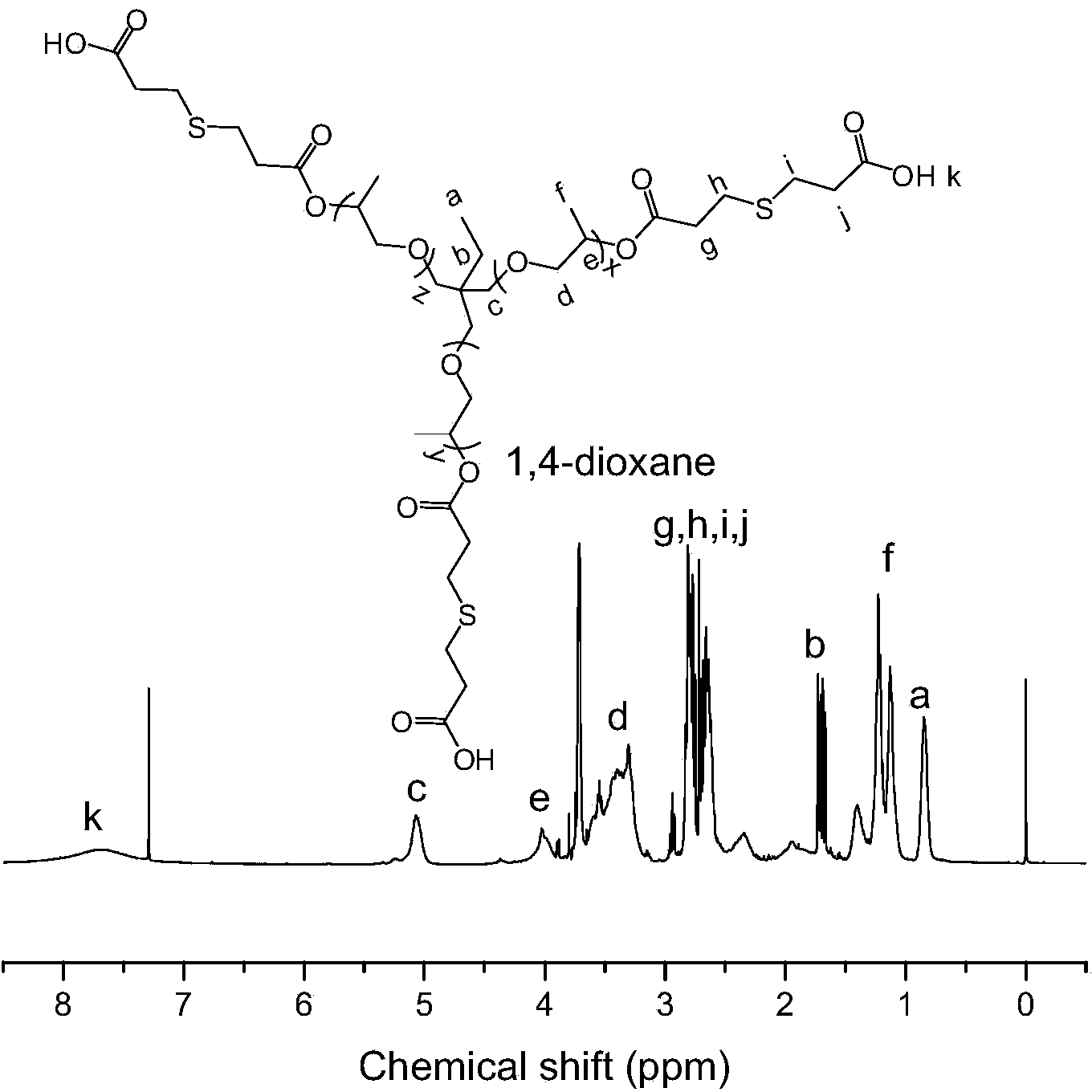

[0024] In a three-necked flask with a stirring device and a thermometer, add 55.4 parts of propoxytrimethylolpropane triacrylate, 38.5 parts of 3-mercaptopropionic acid, and 2.5 parts of benzoin dimethyl ether. Stirring was started, under the condition of nitrogen bubbling, the reaction was irradiated with ultraviolet light for 2 hours, the temperature was cooled and the material was discharged. The resulting product was a colorless, clear, viscous liquid. Since this product has three active carboxyl groups, it can be used as a curing agent for epoxy resins. The H NMR spectrum of the product was tested with an NMR instrument ( 1 HNMR) such as image 3 , showing significant proton signals of propyl sulfide (2.55-2.88ppm) and hydrogen protons on carboxyl groups (7.39-8.45ppm). It shows that the C=C unsaturated double bond has been completely converted into a carboxyl group.

Embodiment 3

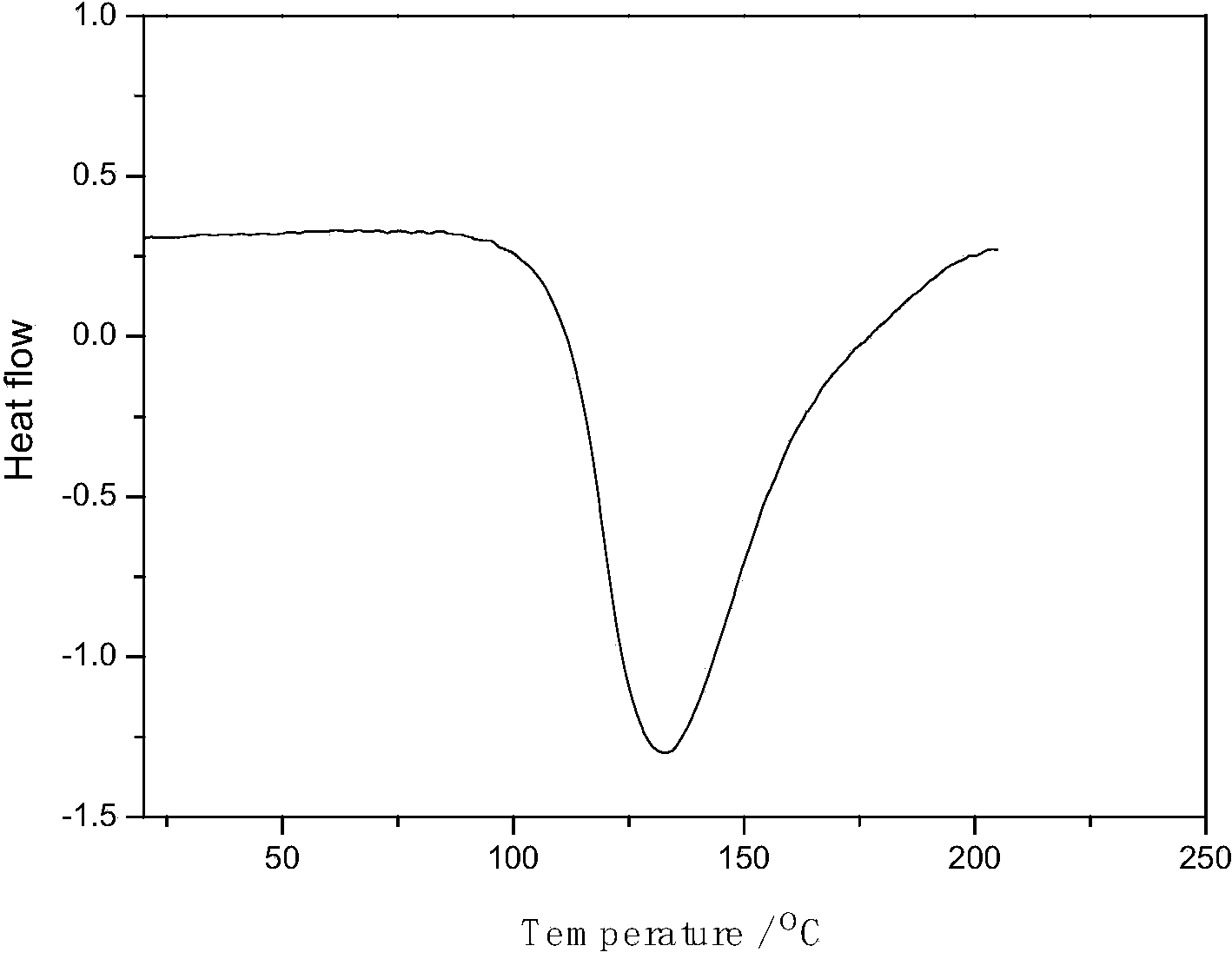

[0026] Add 40 parts of trimethylolpropane diallyl ether, 59 parts of 3-mercaptopropionic acid, and 1 part of azobisisobutyronitrile (AIBN) into a three-necked flask with a stirring device and a thermometer. Stirring was started, and the temperature was raised to 70° C. under nitrogen bubbling, reacted for 8 hours, cooled and discharged. The obtained product is a colorless or pale yellow, transparent, viscous liquid. In order to confirm that the obtained product can be used as an epoxy curing agent, it was mixed equimolarly with bisphenol A type epoxy resin (E-44). The reaction performance of the mixture was measured by differential scanning calorimeter (DSC), and the reaction curve is shown in Figure 4 .

[0027]

[0028] Mercapto-Vinyl Addition Reaction of Trimethylolpropane Diallyl Ether with 3-Mercaptopropionic Acid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com