A rare earth-doped luminescent glass and its preparation method

A technology of luminescent glass and rare earth doping, applied in the field of luminescent materials and their preparation, can solve the problems of high manufacturing cost, decreased luminous efficiency of semiconductor chips and phosphors, and difficulty in controlling the uniformity of luminous color, and achieves a technical bottleneck. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) The design glass mole percentage composition is 60B 2 o 3 -20CaF 2 -10CaO-10Na 2 O: 0.05Eu 2 o 3 ;

[0026] (2) According to the glass composition designed in step (1), accurately weigh 26.8826g of boric acid, 5.6572g of calcium fluoride, 3.6264g of calcium carbonate, 3.8402g of sodium carbonate and 0.0638g of europium oxide, and place these raw materials in an agate mortar Grind thoroughly for 20 minutes, and mix uniformly to obtain glass batch materials;

[0027] (3) Pour the glass batch material into a corundum crucible, put it into a high-temperature furnace for melting, the melting temperature is 1450 ° C, and keep it warm for 1 hour to obtain glass liquid;

[0028] (4) Pour the molten glass into a stainless steel mold preheated at 400°C for 30 minutes to form it, then put it into a muffle furnace for annealing at 450°C for 2 hours, and cool to room temperature with the furnace to obtain a luminescent glass.

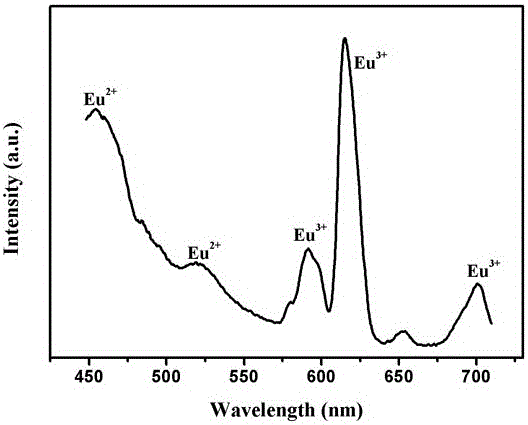

[0029] attached figure 1 is the emission sp...

Embodiment 2

[0031] (1) The design glass mole percentage composition is 35B 2 o 3 -25Al 2 o 3 -20CaF 2 -10CaO-10Na 2 O: 0.05Eu2 o 3 ;

[0032] (2) According to the glass composition designed in step (1), accurately weigh boric acid 16.4880g, aluminum oxide 9.7105g, calcium fluoride 5.9482g, calcium carbonate 3.8130g, sodium carbonate 4.0377g and europium oxide 0.0670g, these raw materials Grind fully in an agate mortar for 20 minutes, and mix well to obtain a glass batch;

[0033] (3) Pour the glass batch material into a corundum crucible, put it into a high-temperature furnace for melting, the melting temperature is 1450°C, and keep it warm for 1 hour to obtain a uniform glass liquid;

[0034] (4) Pour the molten glass into a stainless steel mold preheated at 400°C for 30 minutes to form it, then put it into a muffle furnace for annealing at 450°C for 2 hours, and cool to room temperature with the furnace to obtain a luminescent glass.

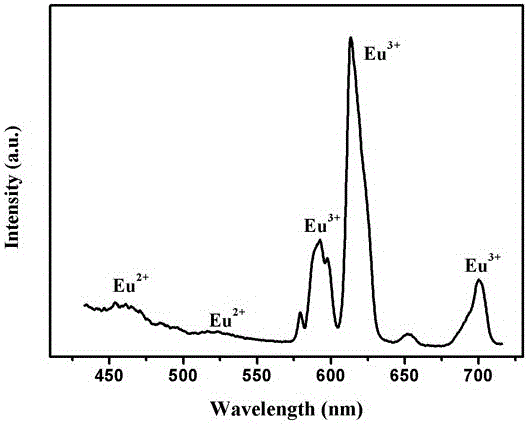

[0035] attached figure 2 For the emission...

Embodiment 3

[0037] (1) The design glass mole percentage composition is 35B 2 o 3 -25Al 2 o 3 -20CaF 2 -20CaO: 0.05Tm 2 o 3 , 0.125Dy 2 o 3 ;

[0038] (2) According to the glass composition designed in step (1), accurately weigh boric acid 16.5069g, aluminum oxide 9.7216g, calcium fluoride 5.9550g, calcium carbonate 7.6346g, thulium oxide 0.0736g and dysprosium oxide 0.1778g, these raw materials Grind fully in an agate mortar for 20 minutes, and mix well to obtain a glass batch;

[0039] (3) Pour the glass batch material into a corundum crucible, put it into a high-temperature furnace for melting, the melting temperature is 1450 ° C, and keep it warm for 1 hour to obtain a uniform glass liquid;

[0040] (4) Pour the molten glass into a stainless steel mold preheated at 450°C for 30 minutes to form it, then put it into a muffle furnace for annealing at 450°C for 2 hours, and cool to room temperature with the furnace to obtain a luminescent glass.

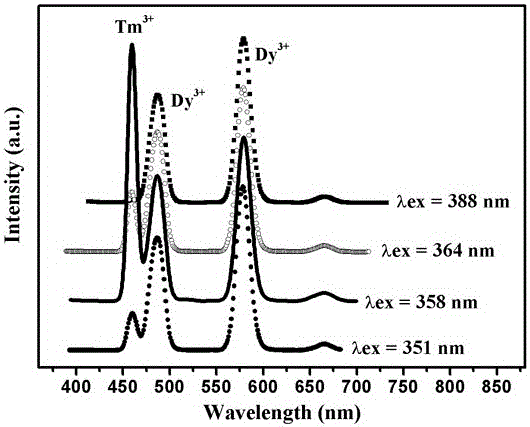

[0041] attached image 3 For th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com