Producing method of electrical steel extremely-thick insulating coating with good film-forming property

A technology of film-forming performance and insulating coating, applied in coating, device for coating liquid on surface, surface pretreatment, etc., can solve the problem of poor film-forming quality, poor scratch resistance of coating, coating peeling, etc. problems, to achieve the effect of facilitating coating adhesion, improving interfacial adhesion, and promoting film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

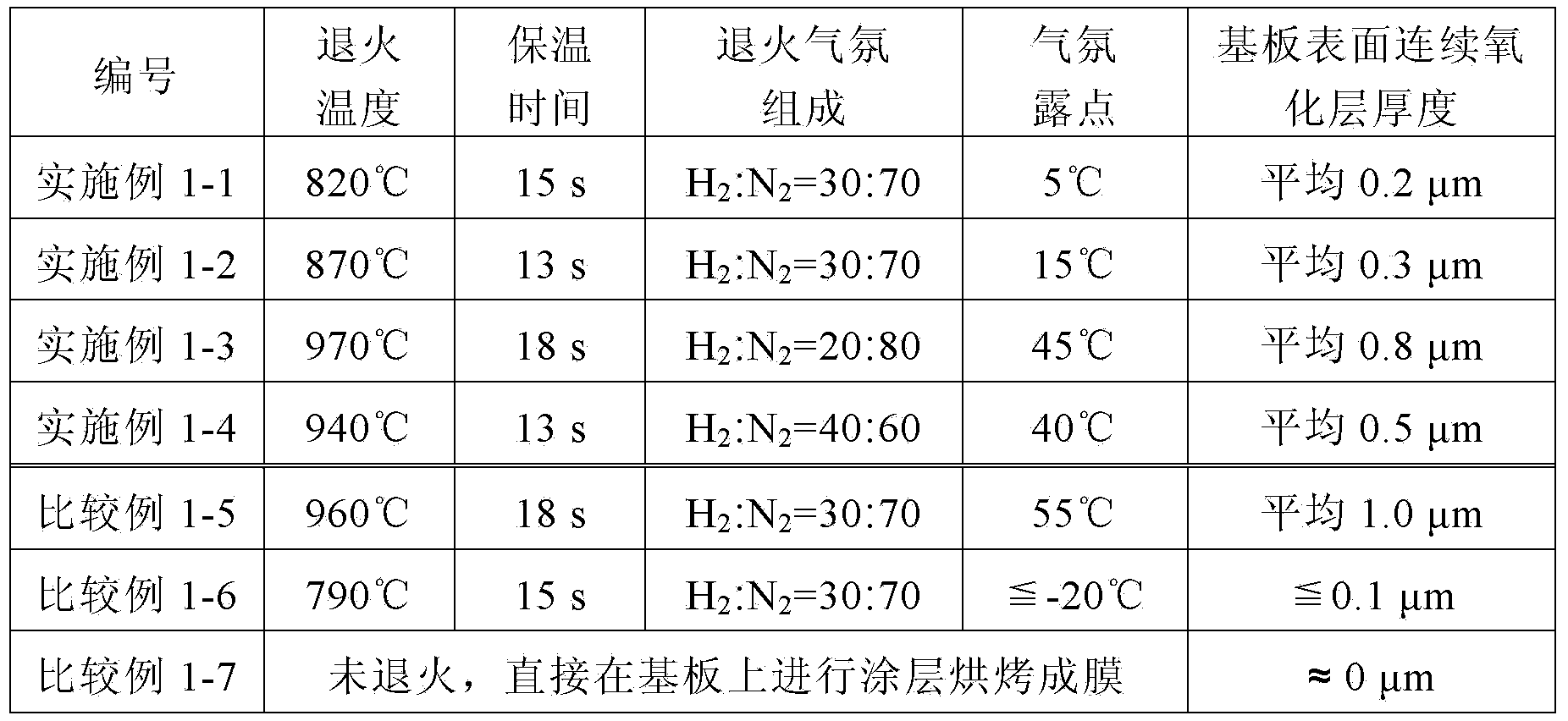

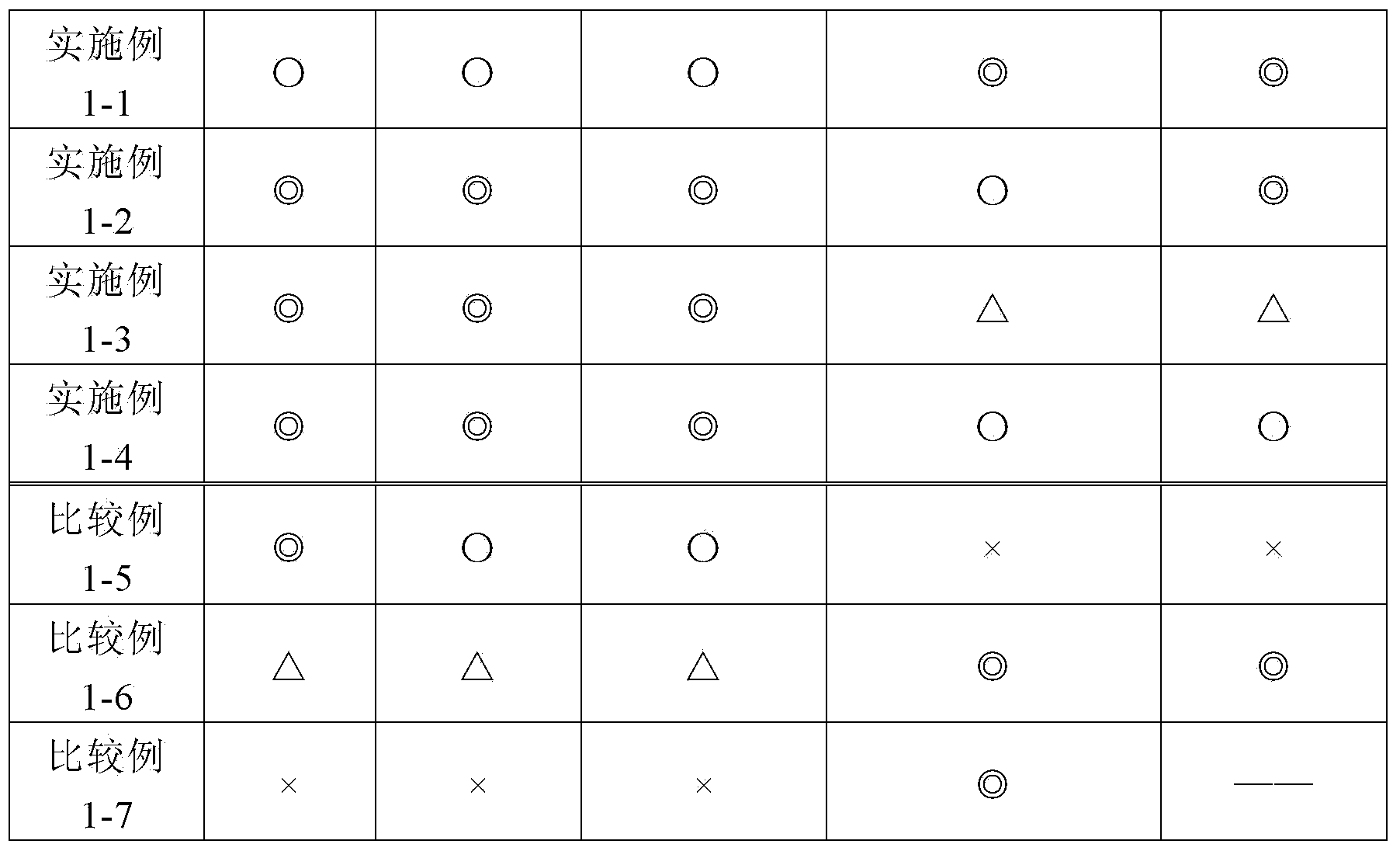

[0038] The effects of different substrate states on the main properties of the coating were compared. See Table 1 for the process conditions of the annealing treatment of the non-oriented silicon steel substrate. The coating solution uses a water-soluble extremely thick C6 insulating coating with an inorganic solid content of 45-55wt% and a total solid content of 70-80wt%. The film is baked under the condition of ℃ plate temperature, and the dry film thickness of one side of the coating is controlled to be 5 μm. The coating performance results are shown in Table 2. It can be seen that the overall performance of the coating after forming a certain thickness of oxide layer on the surface of the substrate before coating is much better than that of the comparative example (the surface oxide layer is too thick or too thin).

[0039] Table 1

[0040]

[0041] Table 2

[0042]

[0043]

[0044] (Note 1: Evaluation symbols are: ◎Excellent; 〇Good; △General; ×Poor)

[0045...

Embodiment 2

[0047] Compare the effects of different coating baking and curing methods on the coating. The process conditions for the annealing treatment of the non-oriented silicon steel substrate adopt the above-mentioned embodiment 1-1, apply the paint on the surface of the substrate with a roller coater as described in embodiment 1, and control the dry film thickness of one side of the coating to be 5 μm; The different baking methods shown (make sure that the plate temperature of each type of process is in the range of 200-280°C, preferably in the range of 240-280°C) correspond to different coating performance results.

[0048] It can be seen from Table 3 that conventional convection baking combined with high-infrared composite heating process has the best comprehensive performance on the coating.

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com