Composite photocatalyst and preparation method thereof

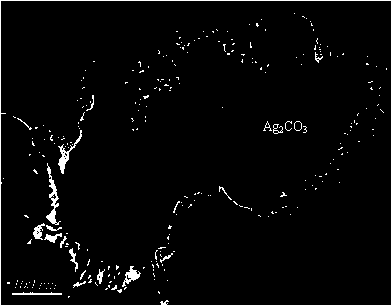

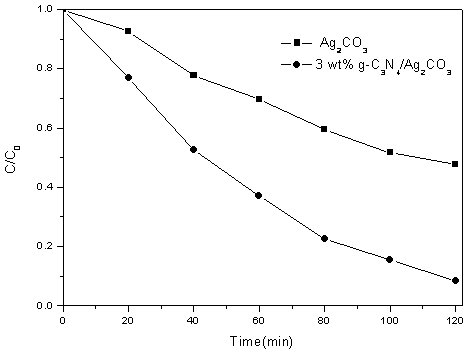

A catalyst and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of limiting photocatalytic activity, narrow energy band gap, large silver carbonate particles, etc. The probability of agglomeration, improving the effective separation, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

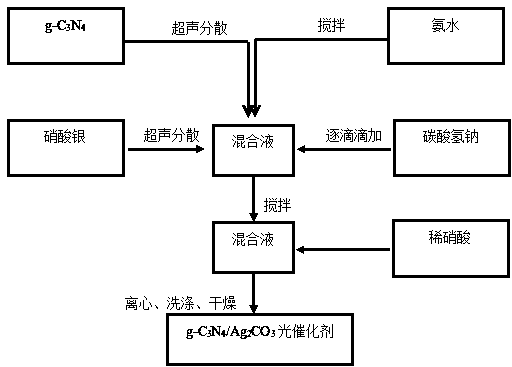

[0029] Embodiment 1: A visible light responsive g-C of the present invention 3 N 4 / Ag 2 CO 3 Composite photocatalyst and preparation method thereof, comprising the following steps:

[0030] (1) Put 0.0172 g of carbon nitride into 30 ml of deionized water for ultrasonic dispersion, and the ultrasonic dispersion time is 30 minutes.

[0031] (2) Add 0.6795 g of silver nitrate to the dispersion obtained in the first step, and ultrasonically disperse for 15 minutes.

[0032] (3) Add commercial-grade ammonia water with a mass concentration of 25-28% to the dispersion liquid obtained in the second step, and the addition amount is 0.5 ml.

[0033] (4) Add 0.336 g of sodium bicarbonate to the mixture obtained in the third step, and stir for 10 minutes.

[0034] (5) Drop dilute nitric acid into the mixture obtained in the fourth step, and keep stirring, test the pH with a glass rod, adjust it to 7, and then stir for 1 h.

[0035] (6) The product obtained in the fifth step w...

Embodiment 2

[0037] Embodiment 2: A visible light responsive g-C of the present invention 3 N 4 / Ag 2 CO 3 Composite photocatalyst and preparation method thereof, comprising the following steps:

[0038] (1) Put 0.056 g of carbon nitride into 30 ml of deionized water for ultrasonic dispersion, and the ultrasonic dispersion time is 60 minutes.

[0039] (2) Add 0.6795g of silver nitrate to the dispersion obtained in the first step, and ultrasonically disperse for 30 minutes.

[0040] (3) Add commercial-grade ammonia water with a mass concentration of 25-28% to the dispersion liquid obtained in the second step, and the addition amount is 0.5 ml.

[0041] (4) Add 0.0336 g of sodium bicarbonate to the mixture obtained in the third step, and stir for 15 minutes.

[0042] (5) Drop dilute nitric acid into the mixture obtained in the fourth step, and keep stirring, test the pH with a glass rod, adjust it to 7, and then stir for 1 h.

[0043] (6) The product obtained in the fifth step wa...

Embodiment 3

[0044] Embodiment 3: A visible light responsive g-C of the present invention 3 N 4 / Ag2 CO 3 Composite photocatalyst and preparation method thereof, comprising the following steps:

[0045] (1) Put 0.0418 g of carbon nitride into 30 ml of deionized water for ultrasonic dispersion, and the ultrasonic dispersion time is 90 minutes.

[0046] (2) Add 0.6795g of silver nitrate to the dispersion obtained in the first step, and ultrasonically disperse for 40 minutes.

[0047] (3) Add commercial-grade ammonia water with a mass concentration of 25-28% to the dispersion liquid obtained in the second step, and the addition amount is 0.5 ml.

[0048] (4) Add 0.0336 g of sodium bicarbonate to the mixture obtained in the third step, and stir for 20 minutes.

[0049] (5) Drop dilute nitric acid into the mixture obtained in the fourth step, and keep stirring, test the pH with a glass rod, adjust it to 7, and then stir for 1 h.

[0050] (6) The product obtained in the fifth step w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com