Nanometer TiO2 film taking expanded perlite as carrier and preparation method of film

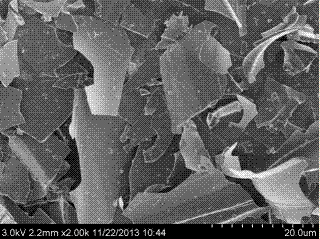

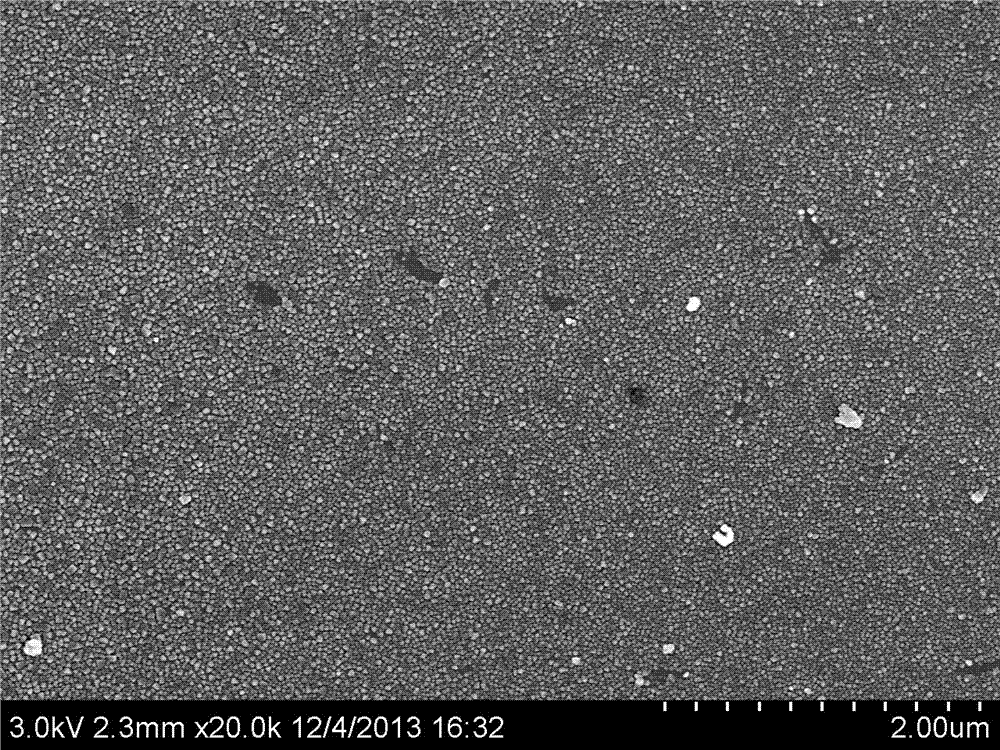

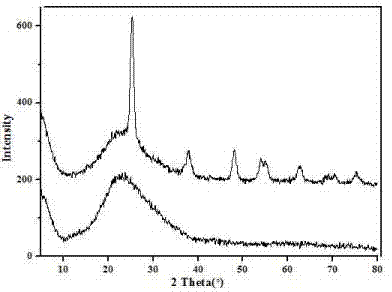

A technology of expanded perlite and nanotechnology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. It can solve the problem of uneven loading of nano-TiO2 particles, a large number of agglomerated blocks, and no expanded perlite package. Covering and other issues, to achieve the effect of dense distribution, good dispersion, high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Implementation 1: Raw material introduction: Expanded perlite comes from Langfang Xinzhong Filter Aid Co., Ltd., the main chemical composition and content are SiO 2 76.95%, Al 2 o 3 12.83%, Na 2 O 4.46%, K 2 O 3.07%, Fe 2 o 3 0.7%. Titanium oxysulfate is chemical grade, white powder, chemical formula TiOSO 4 2H 2 O, containing free H 2 SO 4 ≤8.0%, TiO 2 The content is not less than 38%. Urea is analytically pure, chemical formula (NH 2 ) 2 CO.

[0025] The preparation process steps are as follows:

[0026] (1) First prepare 0.1mol / L TiOSO 4 solution. Weigh TiOSO 4 Add 19.6g (0.1mol) of powder into 1000ml of hot water at a temperature of 40-60°C. Under rapid stirring, the solution gradually changes from milky white to clear, that is, TiOSO with a concentration of 0.1mol / L is prepared. 4 solution;

[0027] (2) Take 10g of expanded perlite and TiOSO with a concentration of 0.1mol / L 4 Solution 250ml, that is, mix according to the solid-liquid ratio of...

Embodiment 2

[0032] Example 2: Identical with raw material and process step in embodiment 1, difference is following process parameter: TiOS0 4 The concentration of the solution is 0.15mol / L, expanded perlite and TiOSO 4 The solid-to-liquid ratio of the solution is 1:25, TiOSO 4 : Urea=1:2 (molar ratio), the temperature in the hydrolysis precipitation reaction is 75°C and the time is 2h, the temperature in the calcination process is 500°C and the time is 2h.

Embodiment 3

[0033] Example 3: Identical with raw material and process step in embodiment 1, difference is following process parameter: TiOS0 4 The concentration of the solution is 0.15mol / L, expanded perlite and TiOSO 4 The solid-to-liquid ratio of the solution is 1:20, TiOSO 4 : Urea=1:1.5 (molar ratio), the temperature in the hydrolysis precipitation reaction is 80°C and the time is 2h, the temperature in the calcination process is 650°C and the time is 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com