Preparation method of chitosan-based drug-loading composite antibacterial superfine fiber membrane

A composite antibacterial and microfiber technology, used in medical science, textiles and papermaking, bandages, etc., can solve the problems of unclear chronic toxicity, need to be further confirmed, and easy oxidation of nano-silver, and achieve good biological phase. Compatibility and biodegradability, promoting wound healing, reducing medical waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

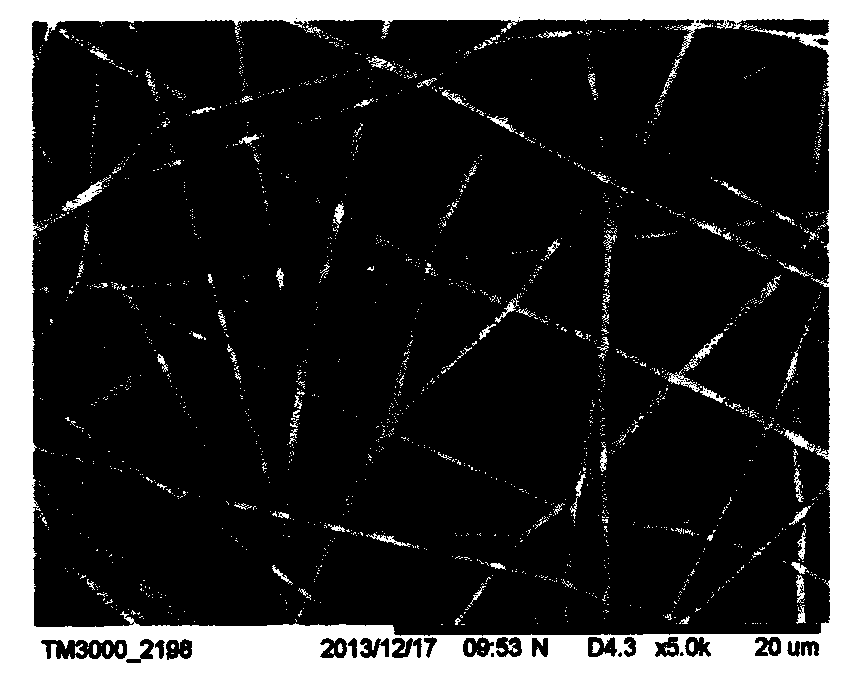

[0028] Take by weighing a certain amount of distilled water and glacial acetic acid respectively with electronic balance, be made into mass fraction and be 90% acetic acid aqueous solution, take by weighing 9.475g mass fraction and be 90% acetic acid aqueous solution, add the ciprofloxacin hydrochloride powder of 0.025g to it , stirred with a magnetic stirrer to fully dissolve, weighed 0.05g of PEO and 0.45g of CS powder and dissolved in the above solution, continued to stir with a magnetic stirrer for 12h, then oscillated with ultrasonic waves for 0.5h, and finally stood for 1h for defoaming to obtain a uniform, Stable spinning solution.

[0029] Add the above spinning solution into the injector for electrospinning, the spinning voltage is 10kv, the feeding rate is 0.5mL / h, the receiving distance is 20cm, the ambient temperature is 18°C, and the relative humidity is 35%. Electrospinning was carried out for 5 h.

[0030] The prepared chitosan-based drug-loaded composite antib...

Embodiment 2

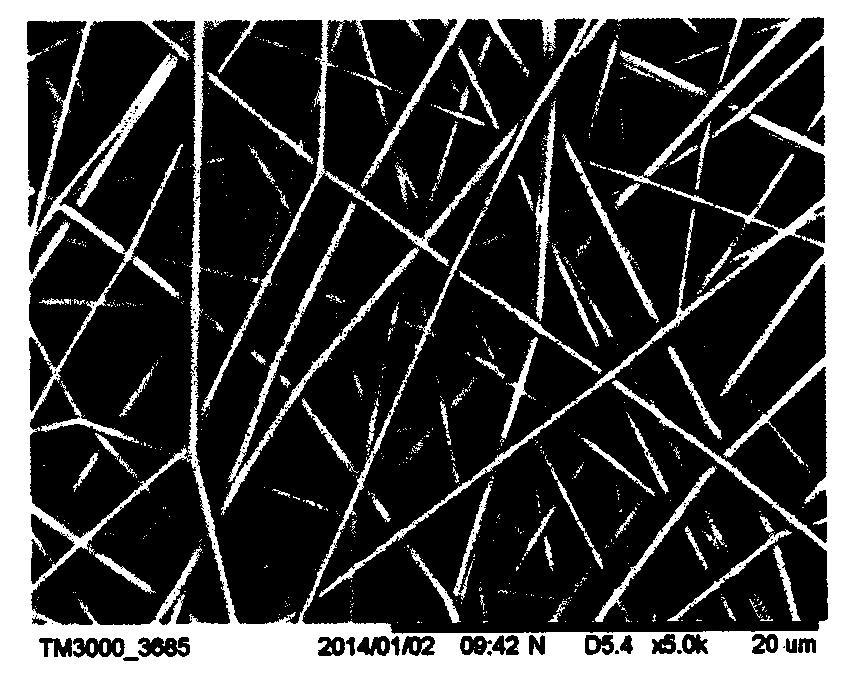

[0033]Take by weighing a certain amount of distilled water and glacial acetic acid respectively with electronic balance, be made into mass fraction and be 90% acetic acid aqueous solution, take by weighing 9.45g mass fraction and be 90% acetic acid aqueous solution, add the ciprofloxacin hydrochloride powder of 0.05g to it , stirred with a magnetic stirrer to fully dissolve it, weighed 0.05g of PEO and 0.45g of CS powder and dissolved in the above solution, continued to stir with a magnetic stirrer for 12h, then oscillated with ultrasonic waves for 1h, and finally stood for defoaming for 1h to obtain a uniform, Stable spinning solution.

[0034] Add the above spinning solution into the injector for electrospinning, the spinning voltage is 16kv, the feeding rate is 0.8mL / h, the receiving distance is 20cm, the ambient temperature is 20°C, and the relative humidity is 30%. Electrospinning was carried out for 5 h.

[0035] The prepared chitosan-based drug-loaded composite antibac...

Embodiment 3

[0038] Take by weighing a certain amount of distilled water and glacial acetic acid respectively with electronic balance, be made into mass fraction and be 90% acetic acid aqueous solution, take by weighing 9.475g mass fraction and be 90% acetic acid aqueous solution, add the moxifloxacin hydrochloride powder of 0.025g to it, Stir with a magnetic stirrer to fully dissolve, weigh 0.05g of PEO and 0.45g of CS powder and dissolve in the above solution, continue to stir with a magnetic stirrer for 12h, then oscillate with an ultrasonic wave for 0.5h, and finally stand for 1h for defoaming to obtain a uniform, stable spinning solution.

[0039] Add the above spinning solution into the injector for electrospinning, the spinning voltage is 10kv, the feeding rate is 0.5mL / h, the receiving distance is 20cm, the ambient temperature is 15°C, and the relative humidity is 40%. Spinning 5h.

[0040] Place the prepared chitosan-based drug-loaded composite antibacterial microfiber membrane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com