Electrode array manufacturing method

An electrode array and manufacturing method technology, applied in the field of electrode array manufacturing, can solve the problems of cochlear fine structure auditory nerve damage, residual auditory nerve stimulation effectiveness, etc., so as to improve biological safety, reduce electric field interference, and improve effectiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

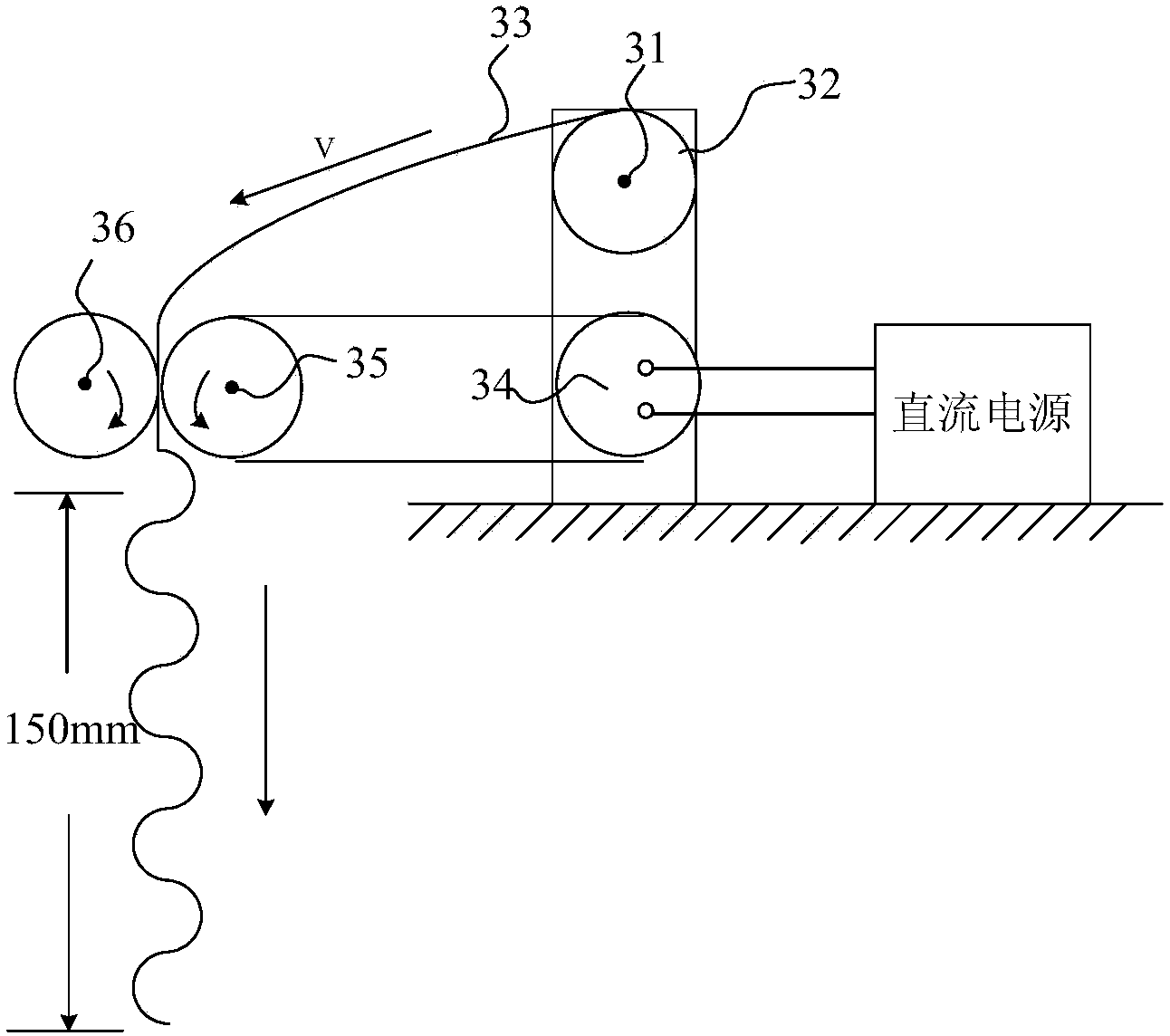

[0016] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0017] The manufacturing method of the electrode array of the present invention provides a safe and effective method for manufacturing the electrode array implanted into the cochlea of a cochlear implant.

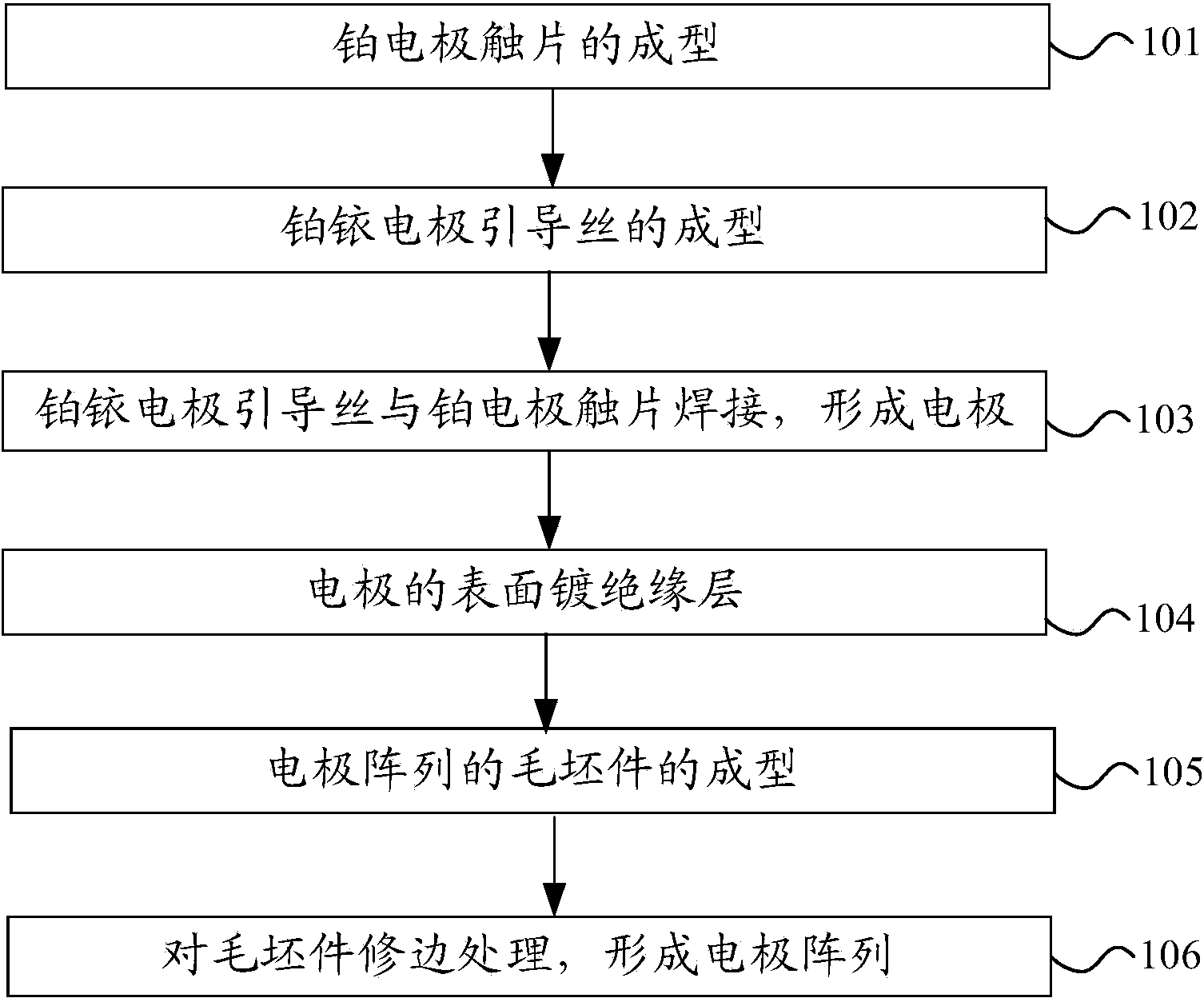

[0018] figure 1 It is a flow chart of the method for manufacturing the electrode array of the present invention, as shown in the figure, the method includes:

[0019] Step 101, molding of platinum electrode contacts.

[0020] Specifically, using special impact equipment and selecting a special stamping die, the selected platinum sheet is stamped to form a platinum electrode contact piece.

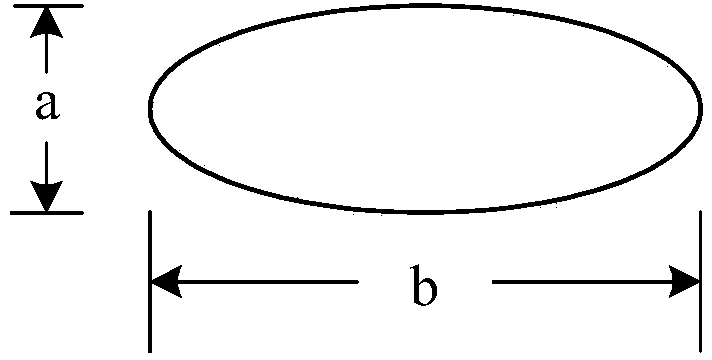

[0021] The electrode contact pieces can have various shapes, one is the electrode contact piece for stimulating the residual auditory nerve, which is oval or circular in shape, and the other is the common electrode for stimul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com