Silicon nitride composite separator and preparation method thereof

A technology of composite diaphragm and silicon nitride, applied in the field of electrochemistry, can solve the problems of complex process, uniformity change of diaphragm, high temperature resistance, etc., and achieve the effects of low cost of raw materials, simple preparation process and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

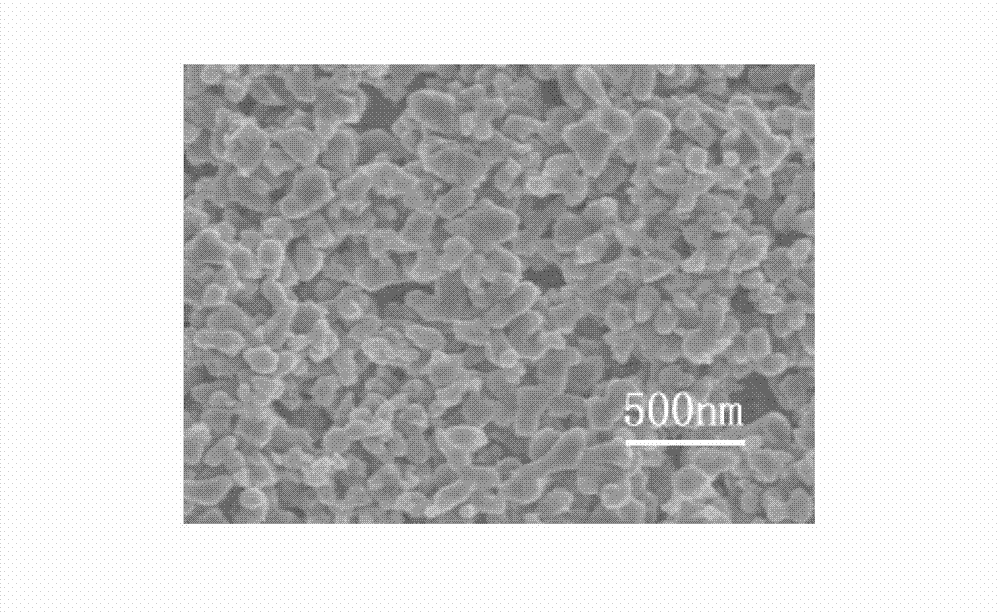

Image

Examples

preparation example Construction

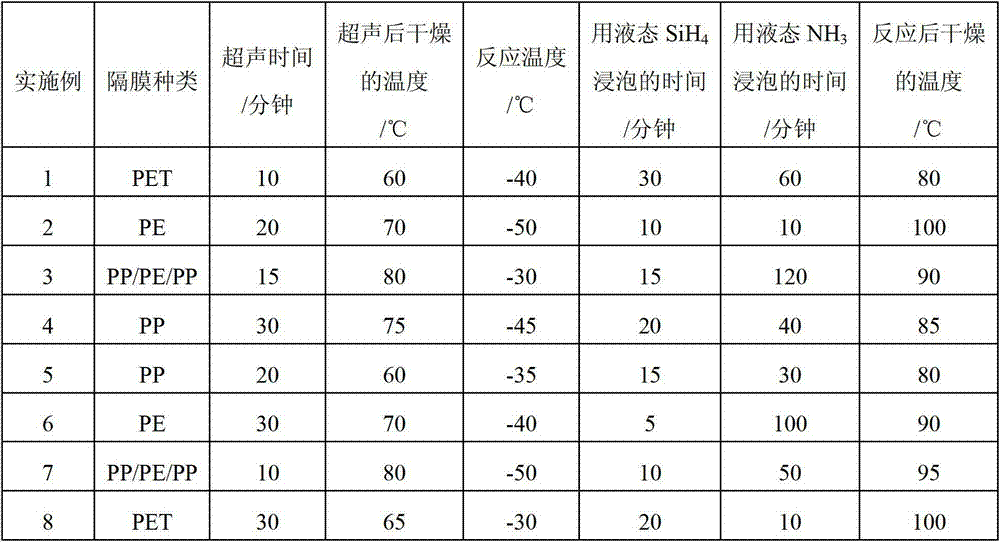

[0019] The preparation method of the silicon nitride composite diaphragm of the present invention comprises the following steps:

[0020] (a) Pretreatment of the diaphragm, ultrasonic cleaning of the diaphragm;

[0021] (b) Immersion of the pretreated separator in liquid SiH at low temperature 4 , then the liquid SiH 4 The soaked septum was taken out and placed in liquid NH 3 in the immersion reaction;

[0022] (c) The reacted separator is taken out and dried to obtain a silicon nitride composite separator.

[0023] In the above-mentioned embodiment, the diaphragm can be specifically a polypropylene diaphragm (referred to as PP diaphragm), a polyethylene diaphragm (referred to as PE diaphragm), and sequentially stacked polypropylene, polyethylene, and polypropylene composite diaphragms (referred to as PP / PE / PP diaphragms). ), or polyethylene terephthalate non-woven diaphragm (referred to as PET non-woven diaphragm).

[0024] Step (a) of the above embodiment is specificall...

Embodiment 1

[0030] First soak the polyethylene terephthalate non-woven diaphragm (PET diaphragm for short) in ethanol solution for 10 minutes, then soak the diaphragm in acetone and ultrasonic for 10 minutes, and finally put it into a 60℃ vacuum drying box to dry to constant weight;

[0031] Then, in a reaction chamber with a temperature of -40°C, the above-mentioned treated membranes were immersed in liquid SiH 4 30 minutes in. Next, from liquid SiH 4 Take out the soaked diaphragm, and a large amount of liquid SiH is attached to the diaphragm at this time. 4 , the diaphragm is placed in liquid NH 3 Soak in 60 minutes to make the liquid SiH attached to the surface of the diaphragm 4 with liquid NH 3 A reaction occurs to generate silicon nitride on the surface of the diaphragm;

[0032] Finally, the separator after the soaking reaction was put into a vacuum drying oven at 80° C. and dried to a constant weight to obtain a silicon oxide composite separator with silicon oxide deposited ...

Embodiment 2

[0035] First soak the polyethylene diaphragm (PE diaphragm for short) in ethanol solution for 20 minutes, then soak the diaphragm in acetone and ultrasonic for 20 minutes, and finally put it in a 70°C vacuum drying oven to dry to constant weight;

[0036] Then, in a reaction chamber with a temperature of -50°C, the above-mentioned treated membranes were immersed in liquid SiH 4 10 minutes in. Next, from liquid SiH 4 Take out the soaked diaphragm, and a large amount of liquid SiH is attached to the diaphragm at this time. 4 , the diaphragm is placed in liquid NH 3 Soak for 10 minutes to make the liquid SiH adhere to the surface of the separator 4 with liquid NH 3 A reaction occurs to generate silicon nitride on the surface of the separator.

[0037] Finally, the membrane after the soaking reaction was put into a vacuum drying oven at 100° C. and dried to a constant weight to obtain a silicon oxide composite membrane with silicon oxide deposited on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com