Silicon wafer aligning method

A silicon wafer alignment and silicon wafer technology, applied in the direction of optics, instruments, photoplate making process of pattern surface, etc., to achieve the effect of improving the efficiency of fine alignment, reducing the loss of the workpiece table, and improving the efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

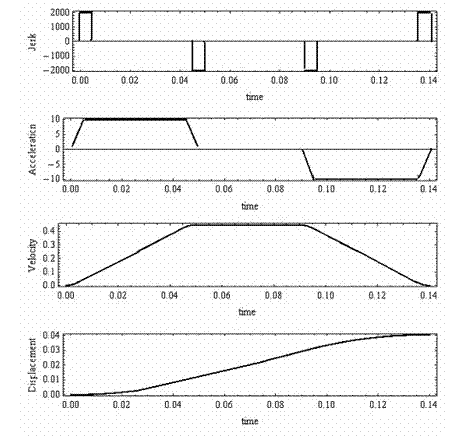

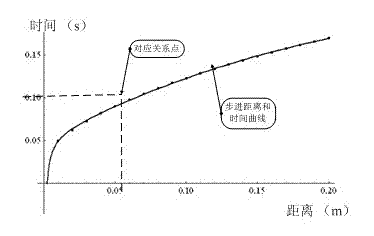

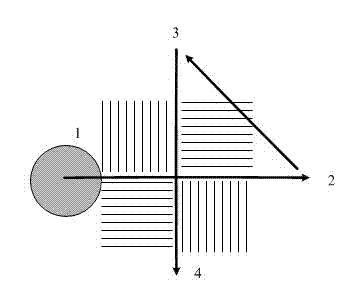

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] In order to better illustrate the technical solution, the following definitions will be made below to help understand the technical solution.

[0050] Wafer Alignment (WA): The function of the wafer alignment device is to complete the horizontal alignment of the silicon wafer and the mask. The radiation beam B is incident on the patterning device (eg mask) MA held on a support structure (eg mask table) MT and is patterned by the patterning device. After having passed through the patterning device (eg mask) MA, the radiation beam B passes through a projection system PS which focuses the radiation beam onto a target portion C of the substrate w. With the help of a second positioner PW and a position sensor IF (e.g. an interferometric device, a linear encoder or a capacitive sensor), the substrate table WT can be moved precisely, e.g. in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com