Method and device for calibrating finishing mill inlet side guide plates

A side guide and finishing mill technology, applied in the field of steel rolling, can solve the problems of deviation rolling, tail flicking, affecting the stability of rolling steel, etc., and achieve the effect of stable position of the arch, ensuring centering accuracy, and high calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

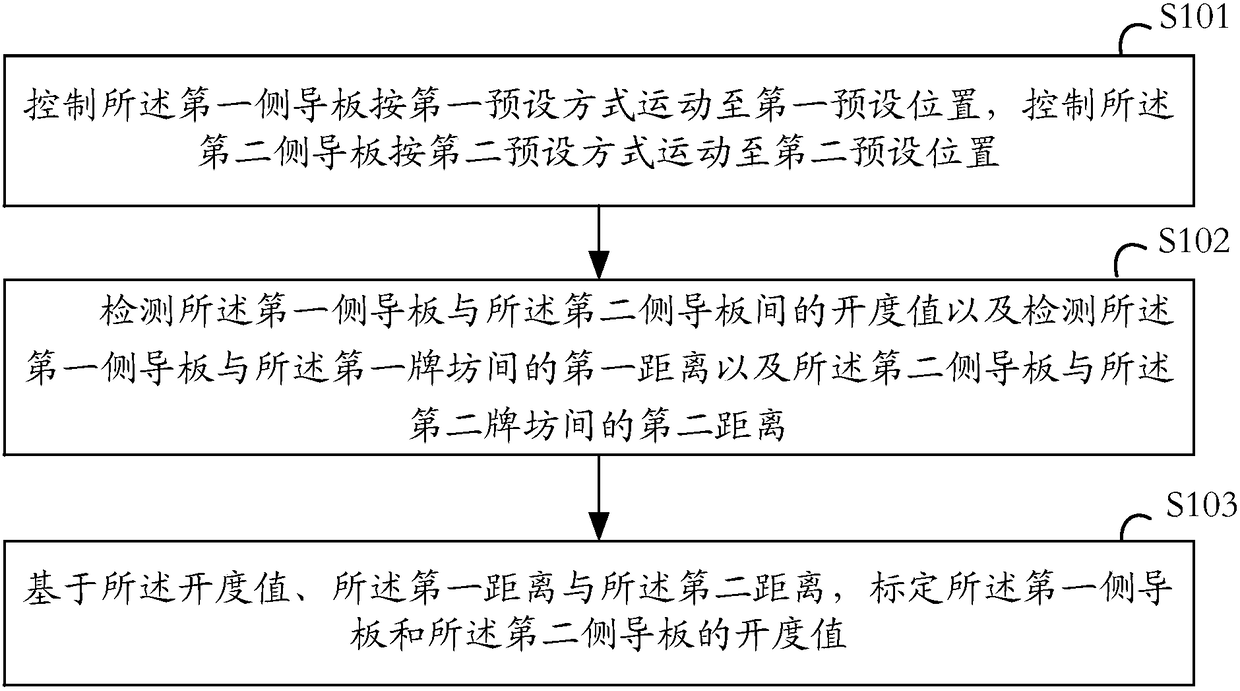

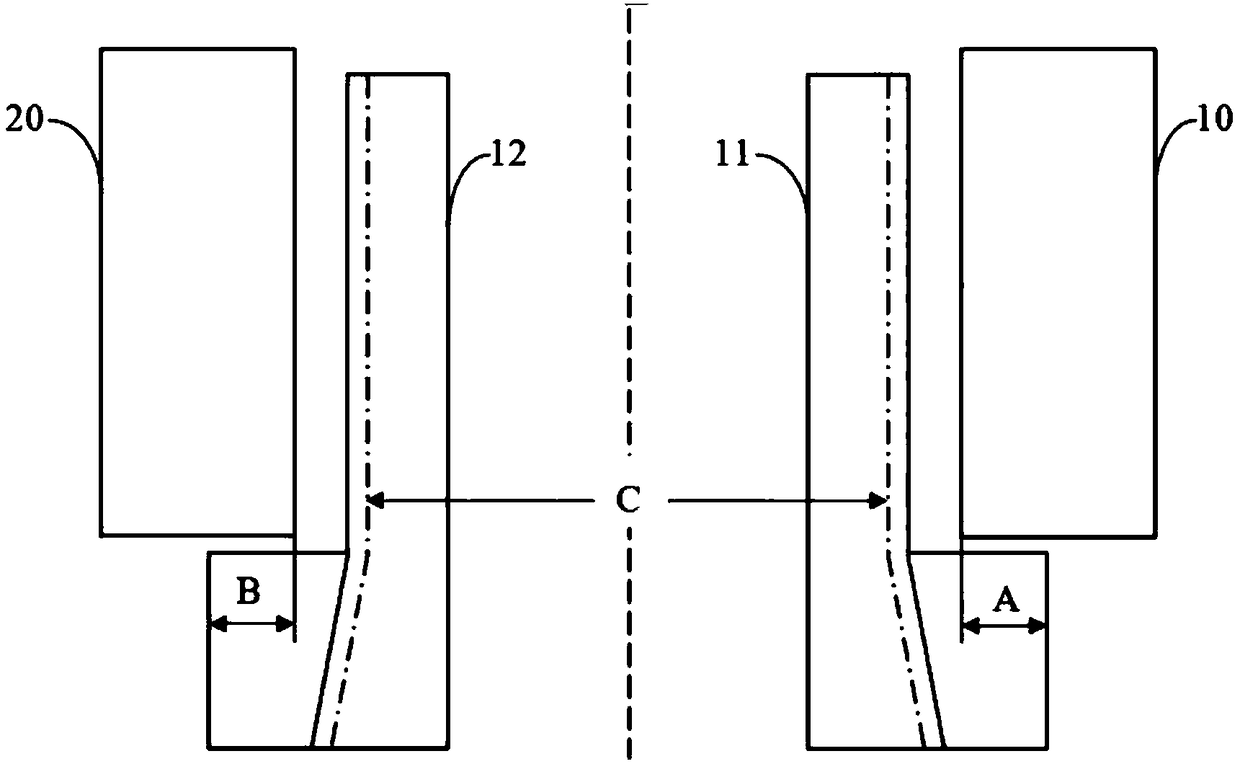

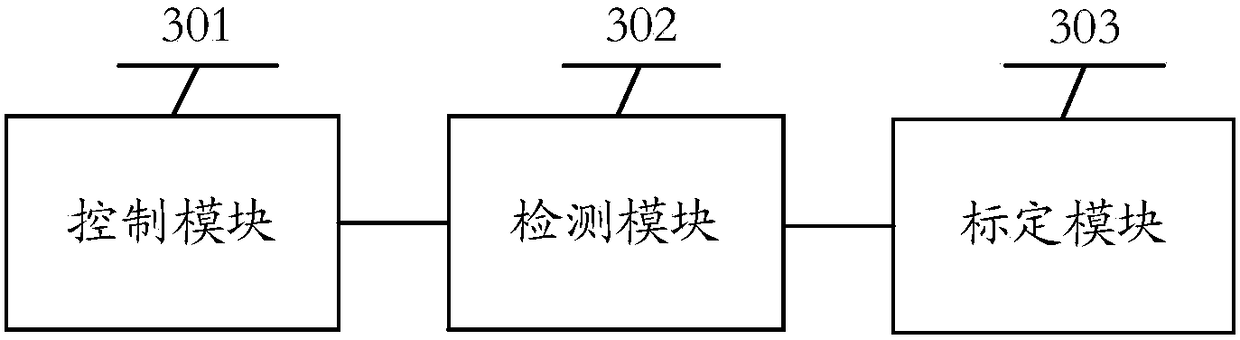

[0049]The embodiment of the present invention provides a method for calibrating the guide plate on the entrance side of the finishing mill, which is used to improve the calibration accuracy of the side guide plate, thereby ensuring the centering accuracy during the rolling process and improving the quality of the strip steel. The method includes: controlling the first side guide plate to move to a first preset position in a first preset manner, controlling the second side guide plate to move to a second preset position in a second preset manner; detecting the The opening value between the first side guide plate and the second side guide plate and detecting the first distance between the first side guide plate and the first archway and the distance between the second side guide plate and the second archway second distance: based on the opening value, the first distance, and the second distance, calibrate the opening value of the first side guide plate and the second side guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com