Three-dimensional elastic rotating color changing fiber and spinneret plate thereof

A three-dimensional, spinneret technology, applied in fiber processing, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve problems such as unsmooth spinning, spinneret angle, and two-component cracking And other problems, to achieve the effect of improving moisture absorption and perspiration function, good visual effect, and good color rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] 1. Raw materials and their specific indicators:

[0028] ECDP chips: intrinsic viscosity 0.58dl / g, melting point 240°C

[0029] PET chips: intrinsic viscosity 0.87dl / g, melting point 265°C

[0030] 2. Spinning process conditions:

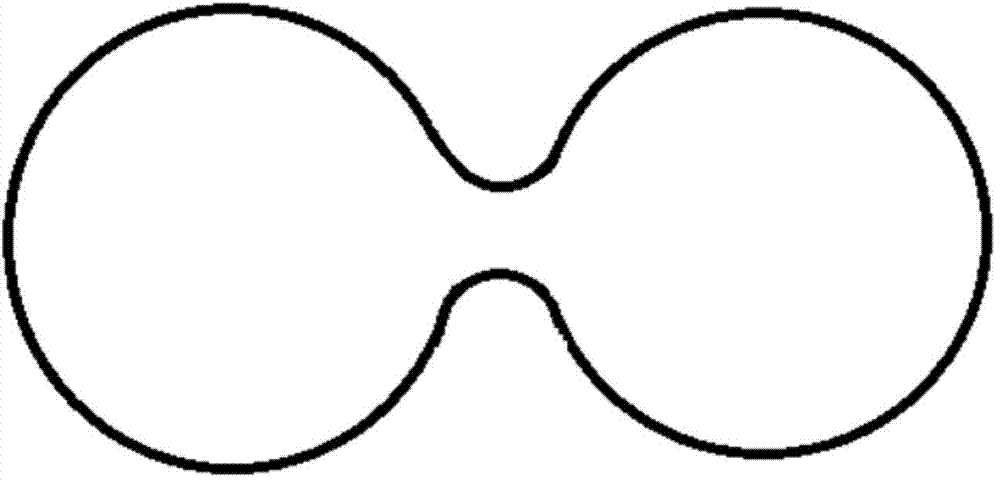

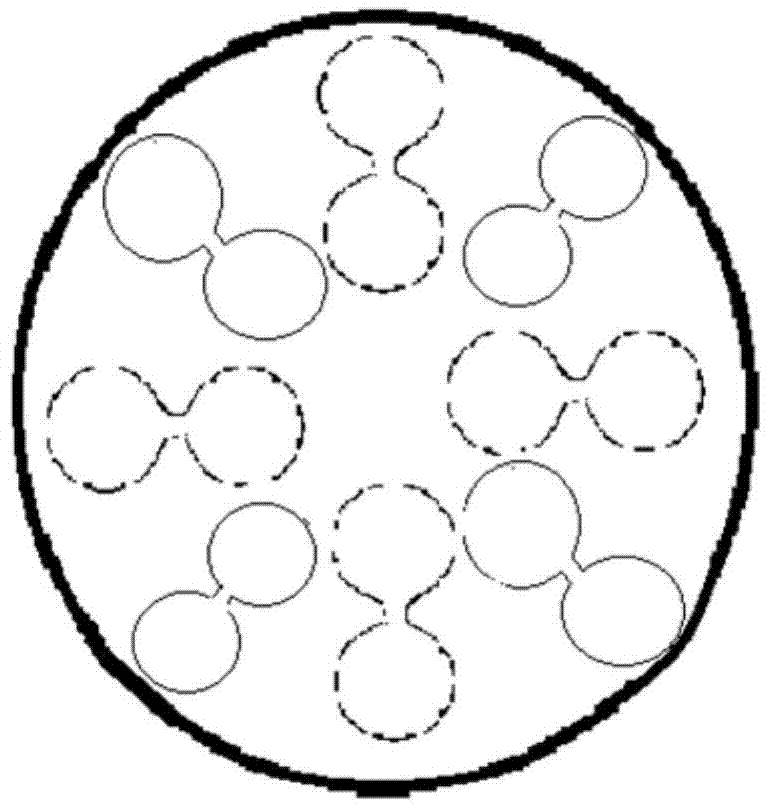

[0031] The ECDP slices with an intrinsic viscosity of 0.58dl / g were vacuum-dried at 100°C for 8 hours, and the PET slices with an intrinsic viscosity of 0.87dl / g were dried; the two slices were sent to a twin-screw extruder for melt extrusion, The melts of the two components use two sets of metering pumps respectively, enter the composite spinning assembly through the melt pipe, and are sprayed out from the spinneret; into, spinneret micropores such as figure 1 As shown, the diameter of the circular hole is 0.34mm; the channel center height of the connecting section is 0.02mm, and the length of the connecting section is 0.04mm. The arrangement of the spinneret microholes is as follows: image 3 shown. The spinning temperature ECDP is 28...

example 2

[0034] Take the preparation of side-by-side composite ECDP / PET side-by-side composite fibers as an example.

[0035] 1. Raw materials and their specific indicators:

[0036] ECDP chips: intrinsic viscosity 0.51dl / g, melting point 238°C

[0037] PET chips: intrinsic viscosity 0.72dl / g, melting point 262°C

[0038] 2. Spinning process conditions:

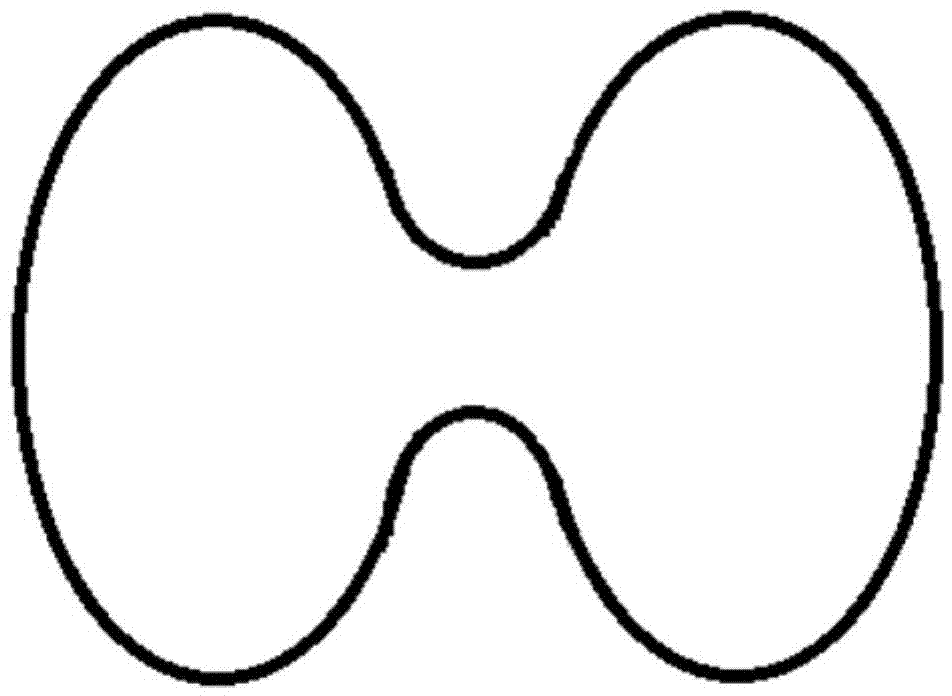

[0039] The ECDP chips with an intrinsic viscosity of 0.51dl / g were vacuum-dried at 100°C for 15 hours, and the PET chips with an intrinsic viscosity of 0.72dl / g were dried; the two kinds of chips were sent to a twin-screw extruder for melt extrusion, The melts of the two components use two sets of metering pumps respectively, enter the composite spinning assembly through the melt pipeline, and are sprayed out from the spinneret; the spinneret micropores of the spinneret are formed by connecting two identical ellipses through the connecting section , spinneret micropores such as figure 2As shown, the long diameter of the elliptica...

example 3

[0042] Take the preparation of side-by-side composite ECDP / PET side-by-side composite fibers as an example.

[0043] 1. Raw materials and their specific indicators:

[0044] ECDP chips: intrinsic viscosity 0.55dl / g, melting point 240°C

[0045] PET chips: intrinsic viscosity 0.80dl / g, melting point 265°C

[0046] 2. Spinning process conditions:

[0047] The ECDP chips with an intrinsic viscosity of 0.55dl / g were vacuum-dried at 100°C for 10 hours, and the PET chips with an intrinsic viscosity of 0.80dl / g were dried; the two kinds of chips were sent to a twin-screw extruder for melt extrusion, The melts of the two components use two sets of metering pumps respectively, enter the composite spinning assembly through the melt pipe, and are sprayed out from the spinneret; into, spinneret micropores such as figure 1 As shown, the diameter of the circular hole is 0.40mm; the channel center height of the connecting section is 0.03mm, and the length of the connecting section is 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com