Preparation process of photochromic polypropylene fiber yarn fabric

A photochromic and preparation technology, applied in textiles and papermaking, etc., can solve the problems of insufficient washing fastness, perspiration fastness and light fastness of photochromic materials, and achieve good thermal stability and discoloration effect. Significant, strong wash fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

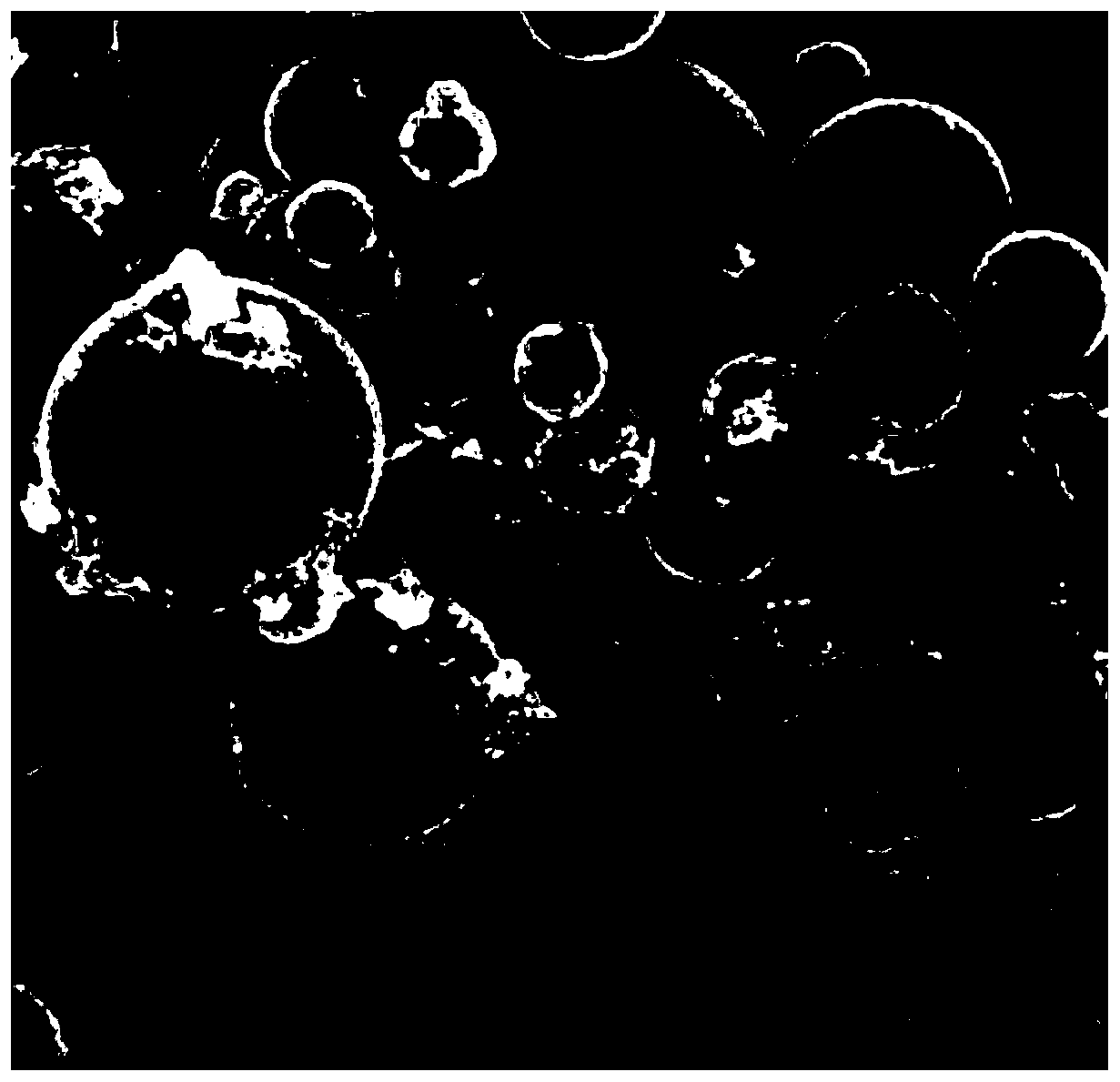

Image

Examples

Embodiment 1

[0023] A preparation process of photochromic polypropylene yarn fabric, comprising the following preparation steps:

[0024] Step 1, preparation of photochromic microcapsules: (1) Take the raw material with a molar ratio of formaldehyde and melamine of 3:1, first react the formaldehyde solution with 1 / 3 of melamine until it is clear and transparent, and use sodium hydroxide to carry out the reaction process. Adjust the acidity and alkalinity to make the system pH=8.0, the reaction temperature is 70°C, stir, then add 1 / 3 melamine to react until the system is clear and transparent, and finally add the remaining 1 / 3 melamine to react until clear and transparent to obtain a transparent prepolymer (2) Weigh the compound paraffin wax added with 20% photochromic solution, add an appropriate amount of emulsifier and deionized water, shear 5min under a high-speed disperser, and stir at a shear rate of 8000rpm to obtain a stable (3) Pour the O / W emulsion into a three-necked flask, stir ...

Embodiment 2

[0034] A preparation process of photochromic polypropylene yarn fabric, comprising the following preparation steps:

[0035]Step 1, preparation of photochromic microcapsules: (1) Take the raw material with a molar ratio of formaldehyde and melamine of 3:1, first react the formaldehyde solution with 1 / 3 of melamine until it is clear and transparent, and use sodium hydroxide to carry out the reaction process. Adjust the acidity and alkalinity until the pH of the system = 8.6, the reaction temperature is 70°C, stir, then add 1 / 3 melamine to react until the system is clear and transparent, and finally add the remaining 1 / 3 melamine to react until clear and transparent to obtain a transparent prepolymer (2) Weigh the compound paraffin wax added with 30% photochromic solution, add an appropriate amount of emulsifier and deionized water, shear 5min under a high-speed disperser, and stir at a shear rate of 8000rpm to obtain a stable (3) Pour the O / W emulsion into a three-necked flask,...

Embodiment 3

[0045] A preparation process of photochromic polypropylene yarn fabric, comprising the following preparation steps:

[0046] Step 1, preparation of photochromic microcapsules: (1) Take the raw material with a molar ratio of formaldehyde and melamine of 3:1, first react the formaldehyde solution with 1 / 3 of melamine until it is clear and transparent, and use sodium hydroxide to carry out the reaction process. Adjustment of acidity and alkalinity, pH of the system = 9.0, reaction temperature 70°C, stirring, then add 1 / 3 melamine to react until the system is clear and transparent, and finally add the remaining 1 / 3 melamine to react until clear and transparent to obtain a transparent prepolymer (2) Weigh the compound paraffin wax added with 40% photochromic solution, add an appropriate amount of emulsifier and deionized water, shear 5min under a high-speed disperser, and stir at a shear rate of 8000rpm to obtain a stable (3) Pour the O / W emulsion into a three-necked flask, stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com