Device and method for recovering residual heat by dry-process granulation of metallurgical slag

A waste heat recovery device and dry granulation technology, applied in the fields of metallurgical engineering, environmental protection and energy saving, can solve the problems of affecting waste heat recovery and utilization, low granulation treatment efficiency, low heat exchange efficiency, etc. Slag treatment effect, good sphericity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

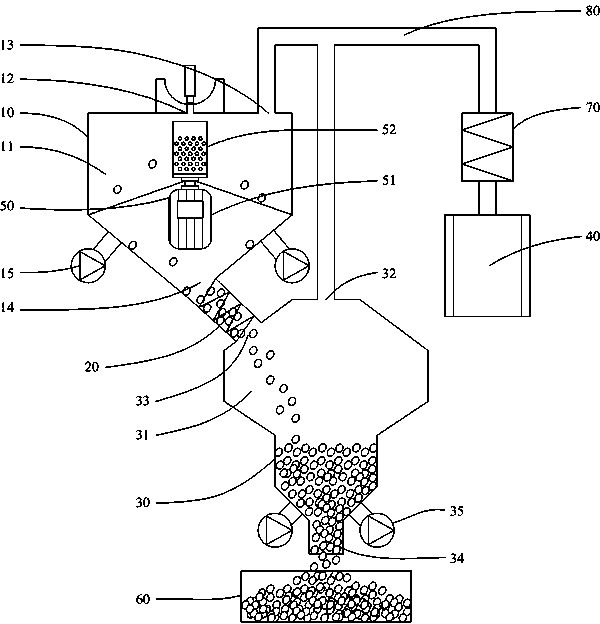

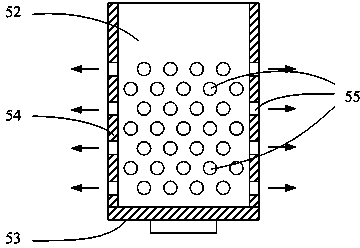

[0061] In the first embodiment, the metallurgical slag dry granulation waste heat recovery device of the present invention is used to perform granulation and waste heat recovery operations on the slag. The porous rotating cup used in the waste heat recovery device for dry granulation of metallurgical slag in this example has a diameter of 40mm, a height of 135mm, a wall thickness of 2mm, an inclination angle of the cup wall of 135°, and an opening diameter of the cup of 1mm. The metallurgical slag used in this embodiment is the blast furnace slag obtained from blast furnace steelmaking, and its main components are as shown in Table 1:

[0062] Table 1 Main chemical composition of slag (wt%)

[0063]

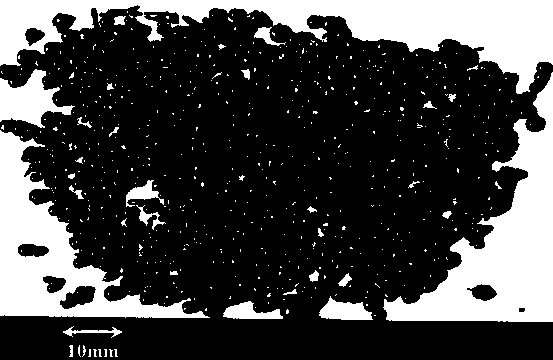

[0064] In this embodiment, the rotation speed of the porous rotating cup of the metallurgical slag dry granulation waste heat recovery device is set to 900, 1200, 1500 and 1800rpm respectively, and the slag temperature is 1450°C. The waste heat recovery device and method were...

Embodiment 2

[0070] In Example 2, the porous rotating cup used in the waste heat recovery device for dry granulation of metallurgical slag has a diameter of 40mm, a height of 135mm, a wall thickness of 3mm, an inclination angle of the cup of 110°, and a diameter of the opening of the cup of 2mm. In this embodiment, the rotating speed of the porous rotating cup of the metallurgical slag dry granulation waste heat recovery device is set to 900, 1200, 1500 and 1800 rpm respectively, and the metallurgical slag dry granulation waste heat recovery device and method of the present invention are used to The blast furnace slag described in Example 1 is subjected to granulation and waste heat recovery operations. The temperature of the slag is 1450°C. The main components of the slag are listed in Table 1, and the average particle size, sphericity and amorphization Rate and other indicators were analyzed, and the results are shown in Table 4 and Table 5:

[0071] Table 4 Slag particle size compositio...

Embodiment 3

[0076] In Example 3, the porous rotating cup used in the waste heat recovery device for dry granulation of metallurgical slag has a diameter of 40mm, a height of 135mm, a wall thickness of 5mm, an inclination angle of 90°, and an opening diameter of the cup of 3mm. In this embodiment, the rotating speed of the porous rotating cup of the metallurgical slag dry granulation waste heat recovery device is set to 900, 1200, 1500 and 1800 rpm respectively, and the metallurgical slag dry granulation waste heat recovery device and method of the present invention are used to The blast furnace slag described in Example 1 is subjected to granulation and waste heat recovery operations. The temperature of the slag is 1450°C. The main components of the slag are listed in Table 1, and the average particle size, sphericity and amorphization Rate and other indicators were analyzed, and the results are shown in Table 6 and Table 7:

[0077] Table 6 Particle size composition (wt%) when the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com