Y2O3-MgO nano-composite ceramic and preparation method thereof

A multiphase ceramic, y2o3-mgo technology, which is applied in the field of Y2O3-MgO nanocomposite ceramics and its preparation, achieves the effects of low cost of raw materials, improved mechanical strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention relates to a novel infrared transparent Y 2 o 3 -MgO nanocomposite ceramics and a preparation method thereof, belonging to the technical field of transparent ceramic preparation. It is characterized in that adopting sol-gel method to prepare Y 2 o 3 -MgO nanocomposite powder, and use spark plasma sintering (SPS) or hot isostatic pressing (HIP) or hot pressing sintering (HP) to prepare infrared transparent Y 2 o 3 -MgO nanocomposite ceramics. When the sol-gel method is used, the metal ions can be mixed at the molecular level, which ensures that the two phases of the prepared nano-oxide composite powder are evenly distributed. In addition, a large amount of heat and gas are released during the reaction process, which improves the crystallization performance and dispersibility of the powder, and reduces the particle size of the powder at the same time. Compared with traditional methods (spray pyrolysis method, co-precipitation method, etc.), the cost of...

Embodiment 1

[0076] At a certain amount of Y(NO 3 ) 3 and Mg(NO 3 ) 2 In the mixed solution, add citric acid monohydrate and ethylene glycol respectively, after the total solution is calibrated to 160ml, the concentration of each component is respectively citric acid 0.25mol / L, ethylene glycol 0.08mol / L, Y(NO 3 ) 3 0.23mol / L, Mg(NO 3 ) 2 It is 0.46mol / L. Stir the solution evenly, put it into a preheated 200°C muffle furnace, raise it to 800°C at 1°C / min, keep it warm for 1h, and then cool down naturally. get Y 2 o 3 -MgO nanocomposite powder. Use absolute ethanol as the dispersion medium for ball milling, then dry and sieve. The treated powder was subjected to discharge plasma sintering, wherein the heating rate was 100°C / min, the holding pressure was 80MPa, the holding temperature was 1100°C, and the holding time was 5min. Anneal in air at 1000°C for 15h. Finally, a high-quality infrared transparent Y 2 o 3 -MgO nanocomposite ceramics.

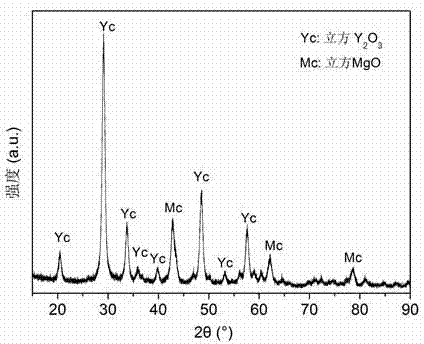

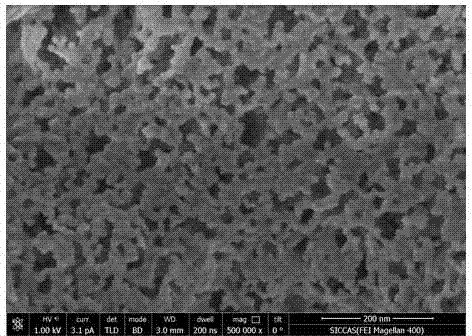

[0077] figure 1 Y prepared for Exam...

Embodiment 2

[0083] At a certain amount of Y(NO 3 ) 3 and Mg(NO 3 ) 2 In the mixed solution, add citric acid monohydrate and ethylene glycol respectively, after the total solution is calibrated to 160ml, the concentration of each component is respectively citric acid 0.25mol / L, ethylene glycol 0.08mol / L, Y(NO 3 ) 3 0.23mol / L, Mg(NO 3 ) 2 It is 0.46mol / L. Stir the solution evenly, put it into a preheated 200°C muffle furnace, raise it to 800°C at 1°C / min, keep it warm for 1h, and then cool down naturally. get Y 2 o 3 -MgO nanocomposite powder. Use absolute ethanol as the dispersion medium for ball milling, then dry and sieve. The treated powder was subjected to discharge plasma sintering, wherein the heating rate was 100°C / min, the holding pressure was 80MPa, the holding temperature was 1200°C, and the holding time was 5min. Anneal in air at 1000°C for 15h. Finally, the infrared transparent Y 2 o 3 -MgO nanocomposite ceramics.

[0084] Figure 6 Y prepared for Example 2 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com