Post-tensioning pre-stress duct grout material for low temperature condition

A post-tensioning prestressing and grouting technology, which is applied to the field of post-tensioning prestressing grouting and post-tensioning prestressing grouting at suitable low temperature. and other problems to achieve the effect of reducing alkali content, improving early strength and uniform slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

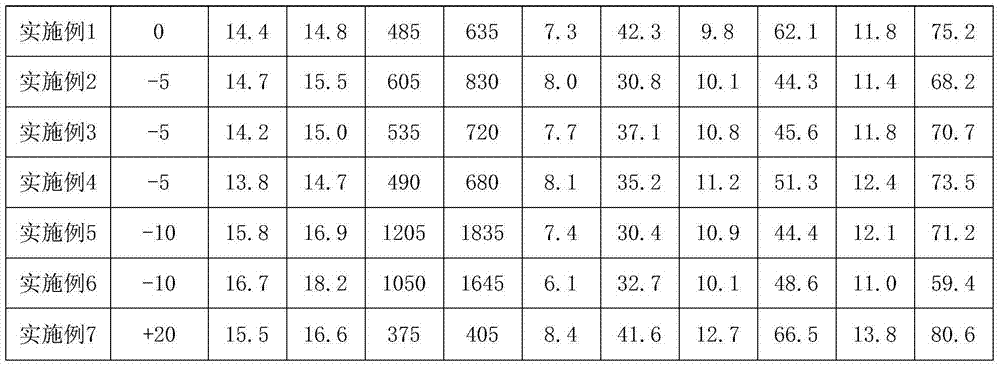

Embodiment 1

[0027] A suitable low-temperature post-tensioned prestressed tunnel press grout provided in this embodiment includes the following components: 85 parts by weight of coagulation-accelerating components, and the ratio is 16:1, that is, ordinary Portland cement (ordinary Portland cement is divided into 80 parts by weight of P.O42.5) and 5 parts by weight of sulphoaluminate cement, 1 part by weight of antifreeze component, 0.4 part by weight of polycarboxylate superplasticizer, 0.04 part by weight of CSA plastic expansion agent, P803 0.035 parts by weight of defoamer, 0.03 parts by weight of polyacrylamide, 0.03 parts by weight of plasticizer (hydroxypropyl methylcellulose), 13.5 parts by weight of mineral admixture, including 12 parts by weight of mineral powder, and 1.5 parts by weight of silica fume , wherein the antifreeze component is a mixture of sodium nitrite and sodium sulfate in a weight ratio of 0.6:0.4. After the grouting material is prepared according to the weight, w...

Embodiment 2

[0029] Same as Example 1, the difference is: 90 parts by weight of coagulation-promoting component, its ratio is 10:1, that is, the weight ratio of ordinary Portland cement to sulphoaluminate cement is 10:1, polycarboxylate superplasticizer 0.35 parts by weight, 8.5 parts by weight of mineral admixture, and its sodium nitrite and sodium sulfate are 0.5:0.5 by weight. The press grouts were tested at -5°C. See Table 1 for the data.

Embodiment 3

[0031] A suitable low-temperature post-tensioning prestressed tunnel press grout provided in this embodiment includes the following components: 90 parts by weight of coagulation-accelerating components, wherein the ratio is 10:1, that is, ordinary Portland cement and The weight ratio of sulphoaluminate cement is 10:1, 1.5 parts by weight of antifreeze component, 0.45 parts by weight of polycarboxylate superplasticizer, 0.05 parts by weight of plastic expansion agent, 0.03 parts by weight of defoamer, and 0.035 parts by weight of polyacrylamide , 0.035 parts by weight of a plasticizer, and 8 parts by weight of a mineral admixture, wherein the antifreeze component is a mixture of sodium nitrite and sodium sulfate in a weight ratio of 1.0:0.5. The grouting slurries were tested at -5°C. See Table 1 for the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com