Condensation system and method for new material processing and production

A new material, condensing tank technology, used in steam/steam condensers, lighting and heating equipment, cleaning of rotating equipment, etc. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

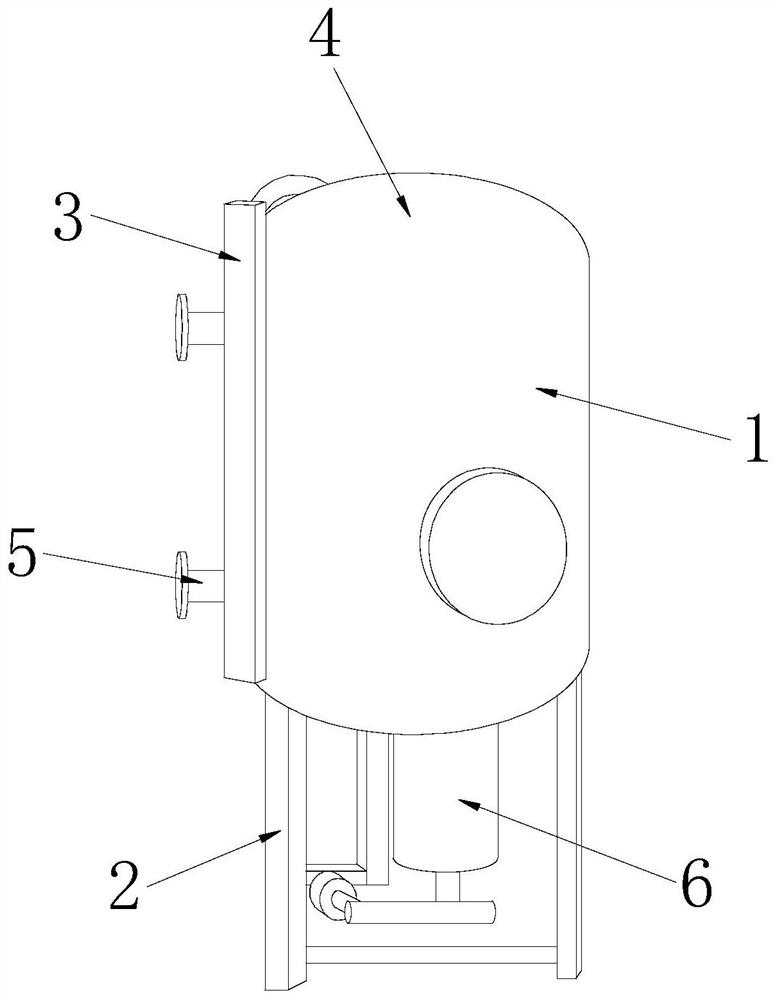

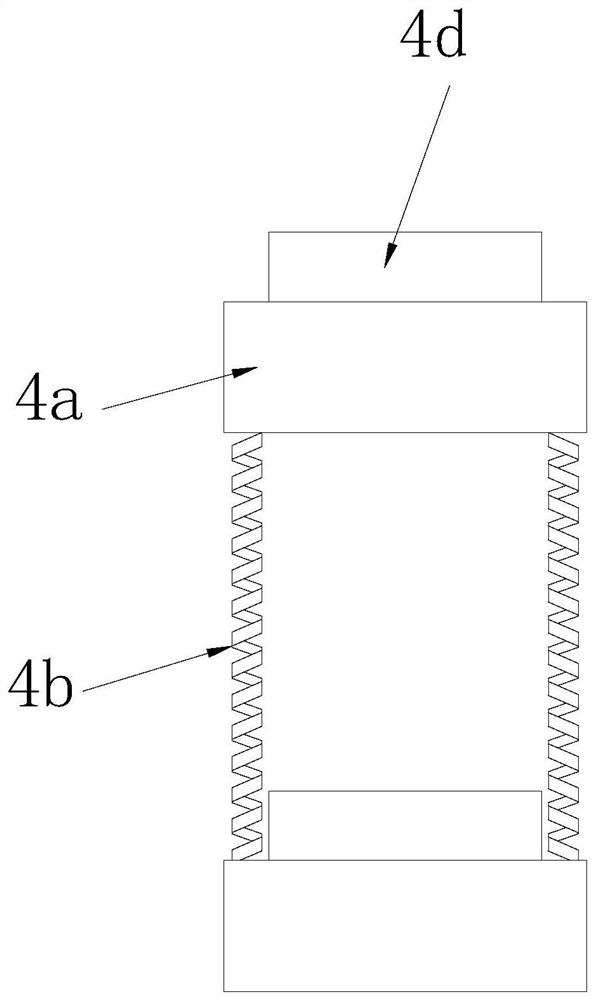

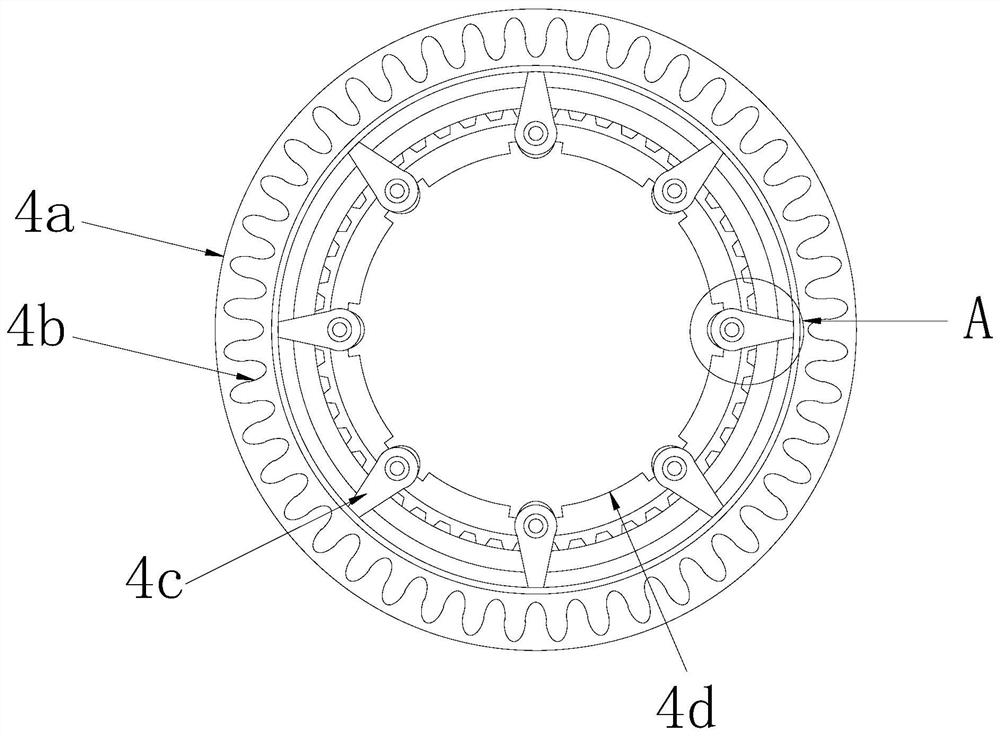

[0029] Such as Figure 1-Figure 5 As shown, the present invention provides a technical scheme of a condensation system and method for new material processing and production:

[0030] Such as Figure 1-Figure 3 As shown, a condensing system and method for processing and producing new materials, its structure includes a condensing tank 1, a support frame 2, a return pipe 3, an anti-scale wall device 4, a water inlet 5, a diversion port 6, and the support frame 2 Installed on the lower surface of the condensation tank 1 and connected by electric welding, the confluence pipe 3 is arranged on the outer surface of the condensation tank 1 and connected by electric welding, the anti-scaling wall device 4 is installed inside the condensation tank 1, the water inlet 5 It is arranged on the outer surface of the condensation tank 1 and connected by electric welding. The diversion port 6 is installed on the lower surface of the condensation tank 1 and connected by electric welding. The an...

no. 2 example

[0038] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 As shown, the present invention provides a technical scheme of a condensation system and method for new material processing and production:

[0039] Such as Figure 1-Figure 3 As shown, a condensing system and method for processing and producing new materials, its structure includes a condensing tank 1, a support frame 2, a return pipe 3, an anti-scale wall device 4, a water inlet 5, a diversion port 6, and the support frame 2 Installed on the lower surface of the condensation tank 1 and connected by electric welding, the confluence pipe 3 is arranged on the outer surface of the condensation tank 1 and connected by electric welding, the anti-scaling wall device 4 is installed inside the condensation tank 1, the water inlet 5 It is arranged on the outer surface of the condensation tank 1 and connected by electric welding. The diversion port 6 is installed on the lower surface of the condensation tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com