Prestressed pore pressure slurry and grouting method thereof

A tunnel grouting and prestressing technology, which is applied in erecting/assembling bridges, bridge construction, bridges, etc., can solve problems such as serious bleeding, abnormal hardening strength, and unguaranteed grouting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

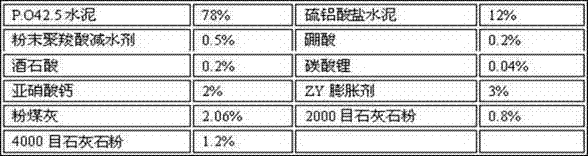

[0054] For on-site construction, select raw materials and mix them uniformly according to the following proportions.

[0055]

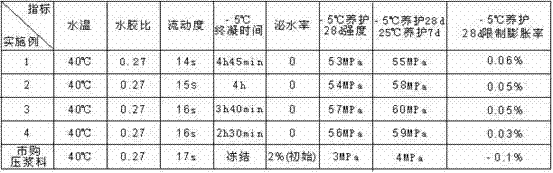

[0056] The water-to-binder ratio is 0.27, and the mixing water temperature is 40°C. Add water first and then pressurize the slurry. Use a mixer with a rotation speed of 1440r / min and a line speed of 15m / s to slurry. After stirring for 5 minutes, press the slurry immediately. See the technical specifications of the slurry. Table 1.

Embodiment 2

[0058] On-site construction, the raw materials are mixed evenly according to the following ratio.

[0059]

[0060] The water-to-binder ratio is 0.27, and the mixing water temperature is 40°C. Add water first and then pressurize the slurry. Use a mixer with a rotation speed of 1440r / min and a line speed of 15m / s to slurry. After stirring for 5 minutes, press the slurry immediately. See the technical specifications of the slurry. Table 1.

[0061]

Embodiment 3

[0063] On-site construction, the raw materials are mixed evenly according to the above ratio.

[0064]

[0065] The water-to-binder ratio is 0.27, and the mixing water temperature is 40°C. Add water first and then pressurize the slurry. Use a mixer with a rotation speed of 1440r / min and a line speed of 15m / s to slurry. After stirring for 5 minutes, press the slurry immediately. See the technical specifications of the slurry. Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com