Welding method for assembly of stainless steel tube

A welding method and stainless steel technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as poor quality, polluting the environment, and low construction efficiency, and achieve the effects of protecting stainless steel pipes, improving work efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

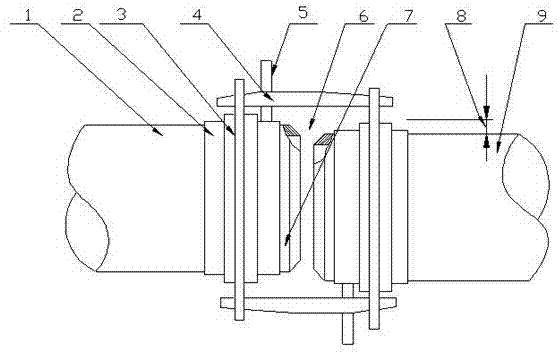

[0054] In this embodiment, two pieces of stainless steel strips 2 are placed on the welding grooves 7 of two stainless steel pipes 1 respectively. The diameter is longer than 20mm; the outer diameter of the stainless steel pipe 1 is between 70-2000mm.

[0055] The distance between the edge of the stainless steel strip 2 and the welding groove 7 of the stainless steel pipe 1 is 2-5 mm. And let the stainless steel strip 2 evenly cling to the outer wall of the stainless steel pipe 1; spot weld the inner and outer laps of the two ends of the stainless steel strip 2 firmly by argon tungsten arc welding and stainless steel welding wire. Preferably, a fine stainless steel welding wire is selected for welding . The pairing tool adopts the external counterpart 3; use the external counterpart 3 matched with the outer diameter of the stainless steel pipe 1 to ride on the stainless steel belt 2 respectively, fasten the external counterpart 3, and make the external counterpart 3 and its m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com